|

Renewable and Sustainable Energy Reviews

Bioethanol from macroalgae: Prospects and challenges |

|

aEnergy & Wetlands Research Group, Centre for Ecological Sciences, Indian Institute of Science, Bangalore – 560012, India.

bCentre for Sustainable Technologies, Indian Institute of Science, Bangalore, 560012, India

*Corresponding author: Ramachandra T.V emram.ces@courses.iisc.ac.in

Deepthi Hebbale , deepthih@iisc.ac.in

|

|

4. Scope and opportunities for macroalgal cultivation

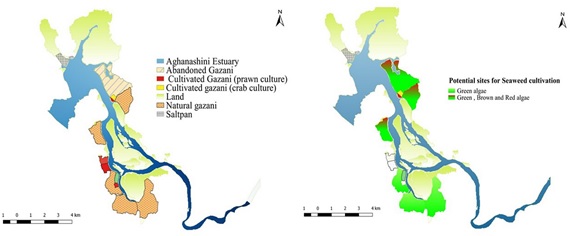

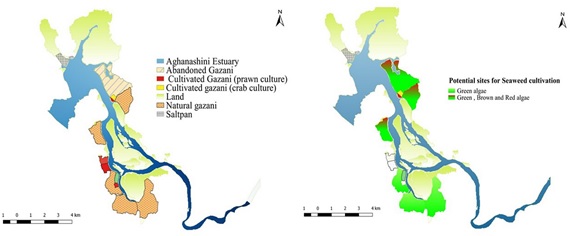

Macroalgal cultivation can be attempted in India by taking the advantage of 2.172 million km2 exclusive economic zone (including Andaman and Nicobar islands) as well as abandoned aquaculture ponds. Aghanashini estuary (Lat 14.391–14.585 N; Long 74.304–74.516 E) situated in Kumta taluk, Karnataka consists of such aquaculture ponds called gazni, which serves as potential site (Fig. 7) for macroalgal cultivation [134]. U.lactuca and E.intestinalis abundantly grows in this estuary during all the season and E.intestinalis naturally occurring in gazni ponds are mostly discarded as waste. Ulva and Enteromorpha genus possess a blade-like or filamentous morphology, which can tolerate wide range of environmental conditions such as temperature upto 40 C [51] and tolerate salinities in the range of 10–60 ppt [188] and resulting in higher [135].

The spatial extent of gazani lands in Aghanashini estuary (Fig. 7) is about 2000 ha (much of it not being used for rice cultivation now) and area of 1000 ha could be considered for algal cultivation during the late monsoon months and subsequently, these lands may be used for shrimp culturing or utilized for other forms of fisheries. The algal production happens indeed without any external input of nutrients, and therefore the gaznis hold very good potential for ethanol production, prior to the commencement of fishery operations, and before salinity rises substantially with the cessation of the rainy season. The algal harvests can be effectively made from any gazni at biweekly intervals, two weeks’ time considered fairly good for harvestable regrowth. It means effectively 1000 ha area are available for algal harvests every week. The lean season for fishery (of prawns and fish mainly) alone needs to be utilized for this purpose, so that prospects for ethanol production, by no means, could come in the way of food production. These 1000 ha of aquaculture areas could be effectively available for algal harvests during the off-season, which might benefit about 2500 small farmers, who were once rice cultivators, who had permitted their erstwhile fields to be converted into shrimp farms, which are not in suitable condition for reintroduction of rice without making substantial structural changes. These gazni lands also exhibit positive correlation with water temperature, air and salinity which influences the growth of diatoms such as Pleurosigma balticum, Melosira sp., Nitzschia sigma and Nitzchia spp. that are potential candidates for biodiesel production [189].

Fig. 7. Potential sites for macroalgal cultivation in Aghanashini Estuary.

Fig. 7. Potential sites for macroalgal cultivation in Aghanashini Estuary.

Cultivation of Ulva and Enteromorpha is estimated to produce annual biomass of 45 t/ha [179] and 100 t/ha [51] respectively, which is 2–20 times the production potential of first and second generation feedstock and 3 times the production of brown algae in temperate waters [179]. Commercial cultivation of these seaweeds largely focuses on high-value food (aonori) and aquaculture feed production. Ammonium are abundantly present in aquaculture effluent, which is readily assimilated by Enteromorpha and Ulva in the range of 50–90 μmol N/g DW h, which makes it feasible to cultivate these algae in aquaculture effluents qualifying as species for bioremediation process [190,191]. However, sporadic sporulation of Ulva leads to loss of biomass due to which attempts of cultivating at large scale has failed, also environmental factors responsible for these sporulation have not yet been completely explored [190]. This can be overcome by technique [135], involving artificial seeding under controlled conditions. This allows control over higher seeding density and consequently biomass production. Seeding density of 621,000 swarmers/m and nursery period of five days were quantified as key factors affecting the growth and biomass yield of Ulva sp. This study also highlights the shorter nursery period and culture cycles required for green seaweeds when compared to red and brown seaweeds.

Large-scale cultivation of macroalgae in open ocean eliminates the need for external inputs such as CO2 cylinders, monitoring of temperature or pH alteration. However in controlled conditions, all these parameters play a crucial role in sustaining biomass productivity. Algae acquire carbon in the form of CO2 or bicarbonates, at pH 8, seawater has alkalinity of 2.3 meq which allows only 0.5 mM of CO2 or 6 mg/l of C to be absorbed from the seawater. In order to increase the level of CO2 absorption pH needs to be increased to nearly 9 which is not feasible as it slows down the photosynthesis [192].In a study [193], brown seaweeds (Sargassum sp.) were cultivated at different pH and temperature and was observed that higher biomass productivity obtained at ambient pH of 7–8.2, indicating that low pH values affected the growth of the algae.

The seaweed industry in India is still at infancy, functioning more like a cottage industry. Seaweeds are collected from the natural stock mainly for the production of agar without any regulations [194]. Macroalgal biomass in addition to being potential feedstock for bioethanol production, also serves as a good food supplement. Enteromorpha was tested as nutritional supplement in preparation of Indian snacks, which resulted in higher iron and calcium content along with increase in proteins, vitamins and dietary fibres [195]. Macroalgal protein, dietary fibres and phytochemicals are utilized in order to enhance the nutritional quality of the food products. Complete utilization of macroalgal biomass into producing biofuel and value added products has potential to ensure India’s energy and food security [134]. The study presents the scope to utilize macroalgal biomass in producing value added products in addition to bioethanol production, bringing resilience to the Industry and improving their economics and usefulness. Prospects of bioethanol with the value added products would support the livelihood of rural population, while aiding as the potential feedstock for biorefinery [36, 196].

|

Citation :T.V. Ramachandra, Deepthi Hebbale, 2019, Bioethanol from macroalgae: Prospects and challenges, Available online 17 October 2019 1364-0321/© 2019 Elsevier Ltd. All rights reserved. https://doi.org/10.1016/j.rser.2019.109479 Received 24 February 2019; Received in revised form 23 September 2019; Accepted 8 October 2019

|