TECHNO-ECONOMIC ANALYSIS OF DEVICES FOR HARNESSING SOLAR ENERGY

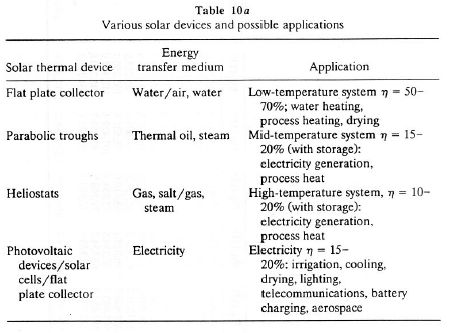

Solar thermal systems and photovoltaic systems are two fundamentally different concepts of solar energy conversion. For solar thermal conversion, a heat-carrying medium (usually liquid or gas) flows continuously through a heat receiver, thus transporting the absorbed heat to the site of thermal use for generation of electricity in a conventional bottoming steam cycle. While photovoltaic systems employ semiconducting compounds having characteristics of the energy threshold and contribute directly to the electricity. The conversion efficiency is independent of system capacity and incoming radiation intensity. As a consequence, a modular design from a few watts to the megawatt scale becomes possible without significant loss in performance even in the case of only moderate insolation. Different solar concepts and possible applications are listed in Table 10a.

Solar Thermal Electric Devices

Parabolic trough, parabolic dish, and central receiver are the three main types of solar thermal electric technologies. Among these, the most advanced type of the "Concentrator" systems is the parabolic trough (De Laquill et aI., 1993). Parabolic troughs track the sun along one axis, concentrating the energy into a receiver tube located at the trough's focal line. Concentration ratios of 10-100 are typically achieved, with operating temperatures of about 400°c. The receiver tube usually has water or oil running through it as the heat transfer medium. This fluid is then piped from each of the parabolic troughs to a central area, where the energy is converted to electricity.

The parabolic dish operates on the same principle as the parabolic trough, but it tracks the sun on two axes, concentrating the energy at the focal point of the dish because it is always pointed at the sun. The concentration ratios of the parabolic dish are considerably higher than the trough of the order of 600-2000, and the operating temperature exceeds 1500°c. The power generating equipment for use with parabolic dishes may be mounted at the focal point of the dish itself, or as with the trough, energy may be collected from a number of separate installations and converted to electricity at a central point. The fomer option is perhaps the most promising use of the dish technology, making it very well suited to remote or stand-alone applications.

The central receiver is a very promising technology for large-scale grid-connected power generation, even though it is at an early stage of development compared with the parabolic trough technology. In this case, heliostats, flat tracking mirrors, concentrate the sun's energy onto a central receiver tower. Concentration ratios are 300-1500, and systems can operate at temperatures of 500-1500°c. Energy losses from thermal energy transport are minimized as solar energy is being directly transferred by reflection from the heliostats to a single receiver rather than being moved through a transfer medium from several receivers to one central point, as with parabolic troughs. Solar to electric efficiencies for test systems are in the range 10-15%.

Photovoltaic Devices

Photovoltaic (PV) modules are made from a number of materials and fabricated in a variety of different designs. The principle is the same for silicon and other semiconductor devices. When sunlight shines on these materials, it frees electrons from fixed sites. The wavelength of the sunlight absorbed depends on the band gap of the material. The materials are designed so that the electrons cannot return to these sites easily except by flowing through an external circuit, thus generating a current. A typical solar cell consists of a layer of semiconductor material sandwiched between conducting top and bottom layers. PV modules are made up of several interconnecting solar cells, as the individual PV cells do not provide much power. PV modules are generally less than 1 m2 in size and deliver between 50 and 150 W of electric power (Thornton & Brown, 1992). The whole is encapsulated in clear waterproof form arrays, either non tracking or tracking. The latter is complex and more expensive but can optimize the system performance. The efficiency of single-crystal silicon modules is about 10-15%, while that of amorphous silicon modules is about 3-5%. However, the manufacturing cost of the latter is much lower.

Cost of Electricity Generation from Solar Thermal Electric Technologies

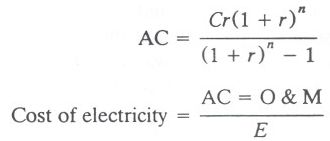

The annual capital cost (AC) is computed assuming r = 0.10 and a lifetime t = 30 years and is given by

where E is the number of units of kWh produced annually (kWh/yr).

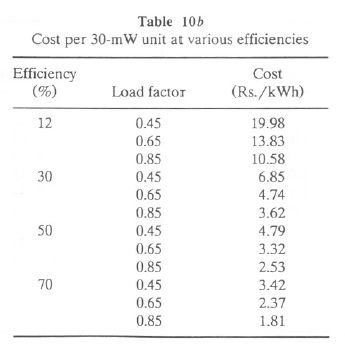

The cost is computed from the quoted capital cost, assuming 2% of capital cost as operation and maintenance (O & M) cost, and the life of the plant as 30 years. The levelized cost or annual capital recovery factor is computed assuming a discount rate of 10%. The cost computed for solar thermal devices for various load factors and efficiencies are listed in Table 10b.

Solar Energy for Water Heating

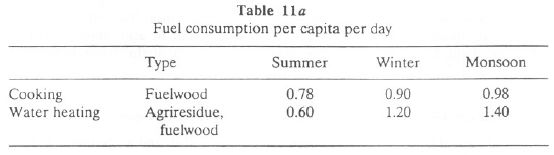

Solar energy for water heating would decrease fuelwood consumption in the domestic sector. A survey of rural households in Kumta concerning trends in fuelwood consumption in the domestic sector (kg/capital / d) is shown in Table 11a.

Tables 11b and 11c list population by taluk and seasonal requirements of fuelwood and agricultural residues (converted to fuelwood equivalent) for water heating and cooking. It is seen, on average, that the coastal belt of Uttara Kannada requires 222.56 kilotonnes of fuelwood for water heating and 185.81 kilotonnes of fuelwood for cooking. A fuelwood survey conducted in the villages of Kumta revealed that about 46.7% of the population take a bath everyday, 32.45% take a bath twice a day during the agricultural season, 32% once every 2-3 days, 12% once every 4 days, and 9.3% once a week.

Solar water heating technology has been well established and functioning satisfactorily in some places in Bangalore for the past 10 years. An integrated solar system with electric immersion heater is satisfactorily supplying the energy needs for all periods and seasons of the year. Only during very cloudy days are immersion heaters used. The cost of such devices is about Rs.12,000 for 200-L capacity and Rs.8000 for l00-L capacity. In the coastal area we have seen earlier that the climate is favorable to set up solar water heating devices to meet the requirement of hot water for bathing purposes. If 30% of the population switches over to solar water heating devices, the fuelwood savings would be of the order of 66.77 kilotonnes/yr from five coastal taluks of Uttara Kannada. Lack of knowledge of technology and nonavailability. of proper service/maintenance backup in this region are the main reasons that energy efficient devices and alternative technology are not finding significant usage in the rural energy scene.

Rural industries like cashew processing are major consumers of fuelwood in rural coastal areas of Uttara Kannada. A preliminary survey conducted in the cashew processing industries has revealed that some industries use fuelwood of the order of 4-8 kg for processing a kilogram of cashews (in boilers, dryers, etc.). Also, these industries are seasonal, operating at peak load during the premonsoon period (February-June). It is possible to switch over to solar energy for conditioning, mild roasting, and Broma drying operations (solar energy is also plentiful during this period).

Drying is one of the most important processes in the postharvest handling of agricultural products such as cardamom, pepper, chilies, copra, and arecanut. Drying of agricultural products is an energy intensive process. It is estimated that to remove a kilogram of water, 2.5 MJ of heat energy is required (Malhotra & Imre, 1990), mainly through fuelwood and other bioresidues.