Chapter 2: Review of literature |

In this review, the first section focuses on the availability, composition and the utilization of the urban wastes as an alternative feedstock for biogas plants. Second section deals with the principles and process details of anaerobic digestion of these materials to energy (biogas). The third section deals with the technology involved in the biogas production process, namely biogas production from USW. In addition, the re-use of anaerobic digestion products, specifically the new applications for digested biomass namely its use as a bio-film support in anaerobic conversion of liquid wastes to biogas.

2.1. USW – sustainable energy resource for future

Brunce and Ernst (1986) define USW as “ the materials collected by the municipality (or) by authorized organization ”. Similarly Cailas et al ., (1996) classify USW as the residues coming from households, commerce, and institution and finally it represents “ all those generated by the activities of the community ” (Buenrostro et al ., 2001).

2.1.1. Problems from illegal disposal of USW

2.1.1.1. Emission of toxic gases

For a long time USW components have been burnt in open peri-urban (rural – urban) tracts with a view to make treatment and disposal inexpensive. It is burnt either as roadside heaps or at dump sites to reduce waste volume and/or to recover the recyclable materials (Srinivas et al ., 2003). Open burning of household wastes is often reported in developing countries (Lemieux et al ., 2004). Such burning also increases annual emissions of green house gases (Sinha, 1997). Such situations emit many toxic chemicals and gases such as carbonyls in addition to the volatile organic carbonyls, poly aromatic carbonyls (Lemieux et al ., 2004), which are dangerous to human health. Open burning of many of the plastic components within USW results in carcinogenic substances such as dioxins (Srinivas et al ., 2003), vinyl-chloride in particular and many other vinyl compounds, CO, CO2, SOx , NOx, tars, chlorinated hydrocarbons, incompletely combusted hydrocarbons and their derivatives, etc. Other than CO2 and CH4 in small quantities of other gases are toxic.

2.1.1.2. Proliferation of vectors

Other than open burning, USW is also dumped in shallow layers in unused areas around towns and cities (Chakrabarti, 2003; Hamer, 2003). In India about 90 % of USW is dumped in low-lying areas (TERI, 1998) and only a small fraction (<10%) is intermittently processed in mechanical compost plants (Shekdar, 1999). Shallow open USW dumps are firstly unaesthetic and second create a potential for parasites and pathogen breeding risks. Although USW may not directly carry large pathogen loads they promote the growth, multiplication and establishment of various insect, nematode, annelid, rodent, etc (CPCB, 2000). The example of the city of Surat that had a protracted epidemic of plague as a result of its open USW dumping and in turn supporting a large rodent population is a classic example (Sundaravadivel, 2000, Venkateshwaran, 1994).

2.1.1.3. Green house gases emissions

The problem of haphazard USW dumping (as also burning) has been growing at an alarming rate. Shallow open dumping is implicated very strongly with emissions of CH4 and CO2– where methane is a GHG gas with a large GHG potential – about 23 times larger than that of CO2 (IEA, 2004). Over a period of time this open dumping is reported to greatly increase the GHG footprint of cities (El fadel., 2001; Garg, 2002; Aitchison, 1996). Such large GHG footprints require large and protracted clean up efforts. The methane emissions are reported to last many years (20-50 years) after the material has been dumped (Aitchison, 1996) and thus the clean up costs are likely to be very high as well (Gupta et al ., 1998)

2.1.2. Origin of USW components

The type of waste and its nature depends largely on its source. The sources of urban wastes include institutions, commercials, parks and gardens, residential areas, and construction and demolition sites etc., (CPHEEO, 2000; Kumar, 2001). A study of the source of USW plays an important role since the source of generation is often the best place to segregate the waste material for reuse, recycling and treatment (CPHEEO, 2000). Buenrostro et al ., (2001) made an attempt to classify the sources of USW. In this study, USW is conceptualized on the solid waste generated within the territorial limits of a municipality independently of its source of generation. Grounded on this assumption, and based on the economic activity that generates a solid waste with determinate physical and chemical characteristics, a hierarchical source classification of USW is suggested. Thus a connection between the source and type of waste is established. This classification enable the assessment of the volume of USW generated and provides an overview of the types of residues expected to be generated in a municipality, region or state. By choosing proper processing options a significant component of the organic fractions in the wastes can be utilized (sometimes utilized many times over). In selecting and designing the waste processing system and disposal facilities, the knowledge of the composition of USW is essential (CPHEEO, 2000).

2.1.3. Generation rate and future scenario

The quantum of solid waste generated in the country is increasing day by day on account of its increasing population and changing lifestyles. USW generated in the city increased from 3200 to 5355 tpd in this same period - registering a growth of around 67% (CPCB 2000). On the other hand, the daily per capita waste generated in India ranges from about 100 in small towns to 500g in large towns (NEERI, 2001) also results in the elevation of its quantity at the rate of 1.0-1.33% annually (TEDDY, 2002). A study conducted by the CPCB, (2000) in country estimates that waste generation from 48 Mt in 1997 is expected to increase to 300 M tpd by 2047 (490 - 945g per capita). This enormous increase in solid waste generation will have significant impacts in terms of the land required for disposing this waste as well as on methane emissions. The burden that the increase in waste generation would impose is evident from the fact that the cumulative requirement of land for disposal of USW in India would reach around 169.6 km 2 by 2047 as against 20.2 km 2 in 1997 (CPCB, 2000). Hence it is very clear that solid waste generation and population growth are highly competitive in the process.

2.1.4. Factors affecting composition

The composition of the waste depends on a wide range of factors such as food, food habits, cultural traditions, lifestyles, climate and income etc (Deepa et al, 2002, Somashekar et al ., 2002). Daskalopoulos et al ., (1998) showed that the population and mean living standard of the country are the two main parameters affecting the annual quantity and composition of the USW generated. Because USW arises as a direct consequence of human activities, the population of a country has been chosen as the first major parameter determining the quantity of waste generated: more the people living in a country, the more waste produced was clearly seen in Table 2.1. The mean living standard (refers to the quality and quantity of goods available to the people) of the population of a country is the second major parameter that can be related to the rate of USW generation. It indicates the ability of the population to consume goods and products and therefore generate waste.

City |

Bangalore |

Kolkata |

Chennai |

Delhi |

Mumbai |

Area (km 2 ) |

226 |

187 |

174 |

1,484 |

437 |

Population (Million) |

5.31 |

6.00 |

5.00 |

12.20 |

12.50 |

USW generation (Tons/day) |

2200 |

3100 |

3050 |

6000 |

6000 |

USW/capita (kg/d) |

0.41 |

0.52 |

0.61 |

0.49 |

0.48 |

Garbage pressure t/km 2 |

9.73 |

16.55 |

17.53 |

4.04 |

13.71 |

| Source: TEDDY, 2002 | |||||

2.1.5. Physical characteristics of USW composition

USW in India can be broadly categorized into organic matter (putrescibles), recyclables and ash materials. Of these three, the organic waste component has remained constant over the past decades at the level of 40% (according to EPTRI, 1995, In India 42.5% was the total compostable matter). The ratio between the other two components has changed in past decades and likely to show further change in the future (Shuchi et al. , 1998). This is mostly due to the occurrence of shift in the usage of recyclable materials namely plastic, paper etc (results of rag picking). Within India, there is a vast difference in physical characteristic of garbage generated by different cities is given in Table 2.2. Paper is the main source of variation and increases with increase in the population. In the Indian context, paper waste generally falls in the range of 3-7%, when the waste reaches the disposal site (Asnani, 1998). The plastic and metal contents are lower than the paper content and do not exceed 1% except in metropolises. This is mainly due to the fact that large-scale recycling of these constituents takes place in most medium and large cities (as a results of rag picking). The biodegradable fraction is quite high, arising from the practice of using fresh vegetables in India.

Cities |

Paper |

Plastic |

Metal |

Glass |

Ash & Earth |

Total Compostable |

Calcutta |

3.18 |

0.65 |

0.66 |

0.38 |

34.00 |

47.00 |

Delhi |

6.29 |

0.85 |

1.21 |

0.57 |

36.00 |

35.00 |

Chennai* |

5.90 |

- |

.70 |

- |

16.35 |

56.24 |

Nagpur |

1.88 |

1.35 |

1.33 |

1.34 |

41.42 |

34.81 |

Bangalore |

4.00 |

2.00 |

- |

1.00 |

15.00 |

78.00 |

Bombay |

10.00 |

2.00 |

3.6 |

0.2 |

45.60 |

40.00 |

*A.P. Jain, 1994;

Source; Background information for Conference of Mayors and Municipal Com-missioners, Urban and Industrial Energy Group, Ministry of Non- Conventional Energy Sources, New Delhi,

1. Cited from: http://www.cleantechindia.com/eicnew/techoption/energy.html, Source: India's Development Report, 1997

2. Cited from: http://mospi.nic.in/comenv2000ta b 7 .4.3.htm

3. 20th WEDC Conference, A.P. Jain, 1994

2.1.6 Chemical Characteristic of waste

Knowledge in chemical composition is essential in selecting proper treatment options for the urban wastes. Chemical analysis of Indian wastes carried out by NEERI, India and others has shown that total nitrogen varies from 0.56% to 0.71%, phosphorous from 0.52% to 0.82%, potassium from 0.52% to 0.83% and C/N ratio is between 21- 31%. Hence the calorific value has been found to be ranging between 800 and 1010 Kcal/kg and density of waste between 330 and 560 kg/m 3 (Asnani, 1996).

2.1.7 Comparison of USW composition with other countries

Comparative physical characteristic of solid wastes produced by cities in developed countries versus that found in Indian cities are given in Table 2.3. This table clearly shows that the quantity of waste produced in developing countries is lesser than that in developed countries. Unlike in developed countries, the wastes of Indian cities have a high fraction of degradable organic matter, from 35 to 75%. This fraction of garbage has a high energy potential (Sharma, 2001), compared to only 12% to 15% of U.S.A and U.K (Table 2.3).

Particulars/component |

India |

UK |

USA |

Switzerland |

Japan |

USW generated (kg/day) |

0.3-0.6 |

0.82 |

2.5 |

0.6 |

1.47* |

Putrescible waste (%) |

31-67 |

13.00 |

15.0 |

14.5 |

36.9 |

Paper (%) |

0.25-8.75 |

50.00 |

54.5 |

33.5 |

24.8 |

Glass (%) |

0.07-1.0 |

6.00 |

9.1 |

8.5 |

3.3 |

Rags (%) |

0.3-7.3 |

3.00 |

2.6 |

3.0 |

3.6 |

Plastics (%) |

0.15-0.7 |

1.00 |

1.7 |

2.0 |

2.2 |

Carbon/nitrogen ratio (C:N) |

25-40 |

44.00 |

50.0 |

40.9 |

NA |

Density (kg/m 3 ) |

250-500 |

128.0 |

NA |

NA |

NA |

| NA-not applicable; * Source: CPHEEO, 2000 | |||||

2.1.8 Power production potential from USW in India

The urban areas of India produce about 30 million t/yr of solid waste (Table 2.4) from household and commercial activities every year. It is estimated that there is a potential of generating about 1000 MW of power (Table 2.5), from MSW in India. Table 2.4 clearly depicts the estimated quantities of different wastes from urban and industrial sectors in the country produced every year (its potential is shown in Table 2.5). Its Energy Recovery Potential (MWe) is shown in Fig 2.1. If this potential sector be effectively used, it will not only contribute substantially to the overall power generation capacity but will also give a good return on investment, apart from improving the environment. In addition to this, pollution load on environment is reduced.

Fig 2.1. Energy recovery potential (MW electrical ) of different wastes from urban and industrial sectors shown in Table 2.4

Source: http://www.undp.org.in/programme/GEF/march00/page12-14.html

2.1.9. World scenario

Table 2.6 shows data on solid waste of three different countries. This table shows the quantity of the solid waste available and its potential for generating electricity, in turn is useful for finding out the country's wealth on renewable source usage.

Country |

Quantity Available (Mt) |

Electricity capacity (kW) |

Electricity Generation (TJ) |

Direct Combustion (TJ) |

Total energy production (TJ) |

Germany |

7.3 |

555000 |

9526 |

19787 |

29 313 |

U.K |

2.6 |

158600 |

4892 |

1340 |

6232 |

U.S.A |

167 |

2862000 |

71405 |

217722 |

289127 |

Source: WEC, 2001

The solid wastes contain valuable resource and potential power is not tapped when utilizing various improper technologies. This problem can be mitigated through adoption of environment friendly technologies for treatment and processing of waste before it is disposed off. These technologies not only lead to generation of substantial quantities of decentralized energy but also reduce the quantity of waste besides improving the quality of waste to meet the pollution control standards (MNES, 2003). Proper treatment option is chosen to utilize these wastes as a raw material to produce some useful material (compost) or energy. The main objective of the treatment option is to utilize the recycling potential and utilization of energy of solid waste, etc. At the same time, the load on waste management system especially, on the disposal is also reduced. Possible conversion routes for these wastes to recover useful (organic fraction) resource are illustrated below (Fig 2.2).

Most of the countries in the world utilized the option of landfill for the disposal of wastes for a long time. The degradable component of the wastes in the landfill gives rise to the liquid and gaseous end products such as leachate and biogas (Jaffrin et al., 2003). The gaseous products of waste decomposition pollute the air and contribute to global warming. Similarly the liquid end product, called leachate, also contributes air pollution (by means of noxious odors) and ground water pollution (by percolation). These problems are clearly outlined elsewhere (IEA bioenergy update, 2004) converting organic wastes into a useful form of energy or compost reduces various environmental impacts. The composting route results in uncontrolled release of CO2 into the atmosphere without capturing energy of the waste (Yu et al. , 2002). Of the above three treatment methods, energy recovery seems to be effective by offering the following advantages:

• The total quantity of waste is reduced by nearly 60-90% depending upon the waste composition and the adopted technology (anaerobic digestion).

• Demand for the land, which is already scarce in cities for the land filling, is reduced.

• The cost of transportation of waste to far away landfill sites is also reduced.

Fig 2.2. Pathways for solid waste treatment for recovery and recycling process.

Inspite of above said methods, the final destination of USW in India is disposal. Most are land filled or dumped (Gerlagh et al., 1999). These wastes followed a different trend of destination in Bangalore city is given in Annexure 1.

2.1.10.1.Types of energy recovery process

Energy can be recovered from the solid wastes either by adopting thermo-chemical technology or by bio-methanation.

2.1.10.1.1. Thermo – chemical conversion

This process involves thermal decomposition of organic matter to produce either heat energy or fuel oil or gas. It is useful for the wastes containing high percentage of organic non-biodegradable organic matter and low moisture content. The main technological options under this category are given in Fig 2.3

• Incineration

• Pyrolysis

• Gasification

Fig 2.3. Pathways available for organic wastes to recover energy.

2.1.10.1.2. Bio chemical conversion

It is based on the decomposition of organic matter by microbiological action to produce methane gas. This option is mostly preferred for the waste having a high percentage of biodegradable organic matter along with high moisture content that aids in microbial fermentation. The main technological option under this category is bio-methanation or anaerobic digestion.

2.1.11. The biomethanation option

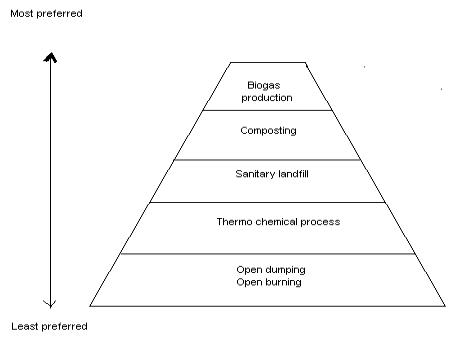

Thermo-chemical processes are cost efficient (Murphy, 2004) but not applicable to the developing countries like India on account of the low calorific value and high organic content of waste (Asnani, 1998; Gerlagh et al., 1999). It is not useful in recovering valuable resources that is possible by anaerobic fermentation (Braber, 1995). This leads to the utilization of anaerobic digestion process for energy recovery. This has the potential to make a significant contribution to sustainable development (environmentally benign and economically secure) (IEA, 2004). One of the principal objectives of anaerobic treatment of solid waste is to reduce the bulk and mass (Lopes et al ., 2004). This will not only generate significant quantity of biogas i.e. about 250-350m 3 /ton of waste (NEERI report, 1996) but also generate the digested material, used as a high-grade soil conditioner (CPHEEO, 2000). It also leads to preventing environment degradation. Thus from Fig 2.4.1 it may be seen that biogas technology is accorded the highest place in the hierarchy of choices. It is effective in terms of treating solid waste along with energy recovery and cost effectiveness. A part of the cost is recovered by substituting fossil fuels and or electrical energy in the treatment process One of the main advantages includes resource recovery without pollution. Residual or digested waste is further composted to yield a good compost. Gas can be used for in-plant as well as for valorization. Thus the recovery of energy in the form of biogas from USW is chosen for this study. Typical biogas composition of organic solid waste is given in Annexure 1.

Fig 2.4.1 : Hierarchy of technological options for OFUSW

2.1.12. Overview of biogas programme in India

Experience with biomethanation systems already exists in India. However, a large part of this is related to farm scale biogas plants and industrial effluents. There is a little experience in the treatment of solid organic waste (CPHEEO, 2000). The National Biogas Management Programme (NBMP) is a modified version of the National Project on Biogas Development (NPBD), which was implemented during 1981-82 to 2001-02. Its main objectives are (i) to provide clean and cheap source of biogas energy; (ii) to produce and use enriched organic manure; (iii) to develop management systems for production of value added products.

Against an estimated potential of setting up of 12 million biogas plants, a cumulative of 3.8 million biogas plants have been set up so far in the country. These include community, institutional, night soil, and family type biogas plants (Table 2.7).

Sources/technology |

Biogas plants |

Units |

Million |

Potential |

12 |

As on March 2003 |

3.8 |

India's Position in the world |

II |

| Source: TEDDY, 2002 | |

2.1.13. Status of biogas production in the world

The yearly production of biogas in the European community was estimated at 430X10 6 m 3 (1990) containing 65% methane or 240,000 tons of oil equivalents (toe; Pauss, 1992). The production from 474 agricultural biogas plants was 60 X 10 6 m 3 of biogas per year. The production from 195 industrial biogas plants was 370 X 10 6 m 3 of biogas per year (Pauss, 1992). Thus agricultural biogas plants in the European community outnumber industrial biogas plants by the ratio of 3 to 1. Type of technologies predominantly adopted for agricultural biogas plants include CSTR (app.250), plug flow reactor (app. 70), batch reactor (50) etc. Whereas for the industrial biogas plants technologies such as UASB (app.55), CSTR (app. 33), up-flow fixed bed (app. 20), down flow bed (app.18) reactors etc. Thus usage of the different technologies employed in the process depends on the type of waste treated.

2.2. Principle of biogas production

Anaerobic biodegradation of organic material proceeds in the absence of oxygen and in the presence of anaerobic microorganisms. It results in two products: biogas (CH 4 - 60% + CO 2 - 40%) and a digested organic matter.

2.2.1 Microbiology and biochemistry of biomethanation

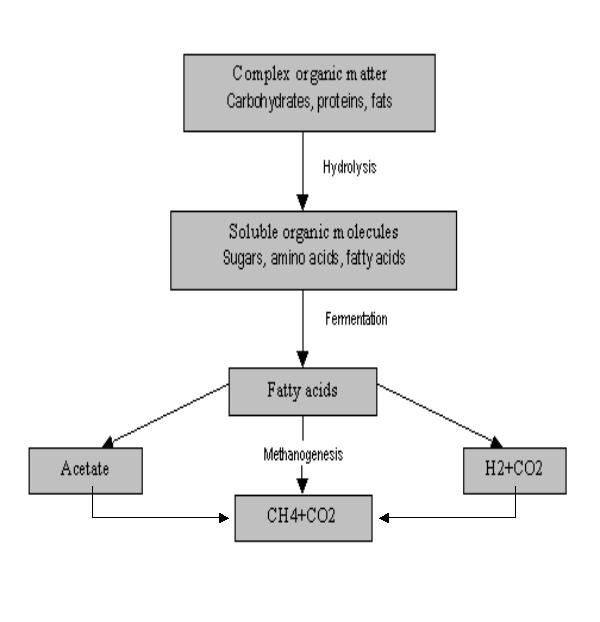

The metabolic reactions that occur during the anaerobic digestion of substrates consists of a complex set of reactions , which are catalyzed by consortia of microbes. These reactions are termed hydrolysis, acidogenesis, acetogenesis and methanogenesis as in the Fig 2.4.2 (Cho et al ., 1995). Mostly bacteria are involved in such a transformation .

Fig 2.4.2. Overall scheme of anaerobic digestion process.

2.2.1.1. Hydrolysis

In the first stage of hydrolysis, or liquefaction, hydrolytic bacteria convert the complex polymers to their respective monomers. For example, celluloses are converted to sugars or alcohols, proteins to peptides or amino acids, and lipids to fatty acids. This is carried out by several hydrolytic enzymes (cellulases, amylases, lipases, proteases etc) secreted by microbes and is presented in Fig 2.5.

Fig 2.5. Anaerobic breakdown of complex organic matter.

2.2.1.2. Acidogenesis

Simpler substances thus formed are converted to long chain fatty acids by acid formers by means of the fermentative reaction. The hydrolytic and fermentative activity is of significant importance in high rate organic waste treatment and sometimes may become rate limiting (Verma, 2002). The acidogenic bacteria has a higher growth rate than methanogens and acetogens (Liu et al., 1997; Bhattacharya et al ., 1996). Thus most often the conversion efficiency of a feedstock is determined by hydrolytic and fermentative action.

2.2.1.3 Acetogenesis

Once many complex intermediates and long chain fatty acids are produced as intermediates, acetogenic bacteria convert long chain fatty acids to simple organic acids (formic, acetic and propionic), carbon dioxide and hydrogen. The principal acids produced are acetic acid, propionic acid, and butyric acid. Acetic acid can even be produced from the CO2 and H2 . Since about two thirds of the methane formed in a biogas reactor is derived from acetate (Gujer, 1983), a decrease in the activity of the acetate utilising methanogens severely affects the anaerobic digestion process. Sometimes conversion of acetate to hydrogen and carbon-di-oxide can also takes place, only at low partial pressures of hydrogen, i.e. in the presence of hydrogen consuming organisms (Schnurer, 1999). The products formed in this phase are due to a number of different microbial species, e.g., Syntrophobacter wolinii , a propionate decomposer and Syntrophomonas wolfei , a butyrate decomposer. Complete conversion of one mole of acetic acid yields 0.78 SCF SI units of methane (Schwartz, 1973).

2.2.1.4 Methanogenesis

Finally in the fourth stage, methane is produced by a group of bacteria called methane formers (also known as methanogens) in two different pathways: either by means of cleavage of acetic acid molecules to generate carbon dioxide and methane, or by reduction of carbon dioxide with hydrogen. Methane production is higher from reduction of carbon dioxide but limited hydrogen concentration in digester results in that the acetate reaction is the primary path for methane (Omstead et al ., 1980). Addition of hydrogen in to the digester alone does not result in methane production thus confirming utilisation of the acetic acid is also possible step in anaerobic reactors (Kumar, 1993). All these products are substrates for methanogens. This phase of anaerobic digestion comprises the activities of two groups of bacteria: hydrogenotrophic and acetotrophic methanogens. The methanogenic bacterial consortium includes Methanobacterium, Methanobacillus, Methanococcus, and Methanosarcina spp ., and Methanothrix spp. These bacteria are highly sensitive to oxygen concentration in the system. Their inactivity depends on an increasing fatty and acetic acids concentration within the environment, consequently lowering the pH (pH needs to be in the range of 6.5 - 7.5). The methanogenic treatment process relies on a balanced symbiotic relationship between metabolically distinct microbial populations such as acidogenic and methanogenic bacteria (Hessami, 1996; Plaza et al ., 1996; Lastella et al ., 2002). The methanogens depend on obligate proton reducing acetogens for the supply of methanogenic substrates (acetate, H 2 and formate). The acetogens in turn depend on the methanogens for the removal of those chemicals. This removal is necessary, because the acetogenic reactions are -= only when those chemicals are at low concentrations. This relationship has been termed as syntrophic, which means, “feeding together”, because they depend on each other for their food. These two groups have an intimate ecological link. However, at short retention times or when inhibitory substances are present in the feedstock, methanogenesis may be incomplete and the acids may accumulate. Accumulation of these acids can lead to digester failure, so methanogenic reactions are crucial for the stable operation of digesters. Stoichiometry of anaerobic reactions likely to takes place inside the digesters is as follows:

| 1. Acidogenic fermentation of glucose: |

C6H12O6 C6H12O6 + 2H2 C6H12O6+ 2H2O |

| 2. Acetogenic oxidation reaction: |

CH3(CH2)2COOH + 2H2O CH3CH2COOH + 2H2O |

| 3. Methanogenic reactions: |

CH3COOH 4H2+ CO2 Source: Denac et al ., 1988 |

Boone et al . (1993) described the investigation of the microbial ecology of the anaerobic degradation of the biomass feedstock showed the presence of Methanosarcina mazei, an acetoclastic methanogen abundant in many biomass digesters can use wide range of substrates such as acetate, hydrogen and carbon-di-oxide (Tabassum, 2000). This was supported by Mladenovska (2000) who reported the presence of Methanosarcina strains, isolated from full-scale reactors treating different kinds of organic wastes could be distinguished from each other by the ability to grow on and utilize acetate. A mixture of several organic wastes gives a more active and efficient population of acetate utilizing methanogens in the reactors. However, some authors had presented entirely different results. Alagappan (1994) studied the kinetics of methanogenic reactions using solid phase biomass fermenters. Results showed that the CO2 reducing methanogens are more and are rapid growers than the aceticlastic methanogens. Aldrich (1993) studied the morphology of Methanobacterium mazei and Methanobacterium thermoautotrophicum abundant in many biomass digesters. In the same year, Hedrick and White studied the application of analytical microbial ecology to the anaerobic conversion of biomass to methane. The results of this application have been used to monitor the operation of a unique design of high solid high productivity methanogenic reactor. McHugh et al. (2003) examined the methanogenic community structures of six anaerobic sludges revealed the presence of Methanosaeta sp.

The role and importance of anaerobic microbes in the biogas production has been presented above. The utilisation of complex substrates by methanogens is also presented. Results discussed above indicate the need for a careful start up of anaerobic digesters.

2.3 Factors affecting anaerobic digestion

Biogas conversion process is microbiological in nature and is affected by the following factors as discussed below.

Anaerobic digestion can occur under two main temperature regimes namely, mesophilic (between 20-45 ° C usually 35 ° C) and thermophilic (between 50-75 ° C usually 55 ° C). Temperature is one of the most common factor affecting methanogenesis processes in a biogas digester (Castillo et al ., 1995; Chynoweth and Pullamanapallil). Enzyme kinetics, dissociation constants and death rates are greatly affected by small changes in temperature. Bacteria present within digesters are influenced by such changes in enzyme kinetics. As temperature rises, enzyme activation increases while at the same time enzyme denaturation also increases. In addition, higher temperature also increases the irreversible destruction of many of these vital proteins. Such mechanisms will cause a typical bacterium to have a range of temperature viability as well as an optimum temperature for growth and functioning (Harmon et al ., 1993). Griffin et al. (1997) found that the mesophilic digester did not respond favorably to an aggressive start-up method. A more gradual start-up improved the digestion process at mesophilic conditions. Yu et al ., (2002) showed that the retention time in a two-phase system could be reduced by heating or preventing heat loss (insulating). Castillo (1995) showed, that the temperature at 25 ° C was economical, since the biogas production was more homogenous and constant. This influences the gasholder capacity whereas at the increased temperature (35 ° C) the energy consumption by the process was greater than energy from the additional biogas produced. Thus the low temperature operation was economic and sustainable (Castillo et al ., 1995). The optimum temperatures for anaerobic digestion are either 35 ° C or 55 ° C, mostly depending on the application and its operating conditions (Hessami et al ., 1996).

2.3.2 pH

The pH is known to affect enzymatic activity owing to the fact that only a specific and a narrow pH range are often suitable for the maximum activity. A pH range between 6.7-7.4 is reported suitable for most methanogenic bacteria to function (Verma, 2002). The rate of methanogenesis may decrease if the pH is lower than 6.3 or higher than 7.8. The main reason for the absence of biodegradation was the rapid acidification of the waste (Verma, 2002). This is generally due to the over production of VFA by the activity of hydrolytic acidogenic bacteria capable of degrading the waste in the first few days of incubation (Gomec, 2003). The biological evolution of methane is inhibited at acid production phase. Saturating the waste with water could reverse this inhibition (Martinez, 1999). Gomec, (2003) studied the effect of pH on hydrolysis/acidogenesis in terms of soluble chemical oxygen demand (SCOD) and VFA production as well as TSS and VSS destruction both in the anaerobic solubilization of domestic primary sludge and activated sludge at mesophilic temperature. Results indicate that the pH control enhanced the biogas production. This was due to an increase in SCOD, resulting from a quicker hydrolysis and fermentation during the first 5 days. Besides, total COD removals were calculated at higher quantities in the pH controlled reactors indicating that pH control increased the performance of the anaerobic digestion.

The long chain fatty acids were found to be inhibitory to the several kinds of essential reactions in the anaerobic digestion because of their toxicity to the bacteria (Hanaki et al ., 1980). The rate of methane production from hydrogen was lowered by long chain fatty acids. The methane production from acetate was inhibited so strongly that a long lag period appeared. Wang et al ., (1999) investigated the efficiency of anaerobic digestion to evaluate the effect of C2-C6 VFAs on the methane fermentation and to examine the behavior of VFAs in anaerobic digestion. The VFA concentrations and methane production in anaerobic digestion were increased by pretreatment methods such as ultrasonic disintegration, thermal and freezing treatments. This experiment clearly shows that decomposition rates of the VFAs with a straight chain were greater than those of their respective isomers with a branched chain. Inhibition of degradation of the VFAs by acetate in a digester was also examined. It is known that VFAs are important intermediary compounds in the metabolic pathway of methane fermentation and cause microbial stress, if present in high concentrations resulting in a decrease of pH and ultimately leading to a failure of the digester. Hence it is necessary to investigate the optimum conditions and efficiencies of digesters by examining VFAs. Pind et al ., (2002) focused on the effects of VFA on the anaerobic process, showed that the high concentrations of propionate affected the degradation of all VFAs. At shorter retention times, VFA production could exceed the utilization rates, leading to the digester failure (Ghosh, 1991).

2.3.4 Inoculum-substrate ratio

Fernandez, (2001) reported that the ISR variation has less impact on anaerobic degradability than on specific methane productivity (SMP). While maximum anaerobic degradability was reached in those tests with high ISR, the greatest values of SMP were with the lowest values of ISR ratio. A low ISR caused a slow hydrolysis, although the methane production was fast. Lopes et al.,( 2004) affirmed that the inoculum used in the process, substantially improved the performance of the process. For this study, Lopes used bovine rumen fluid as an inoculum for the organic fraction of solid waste. Results clearly indicated that the better performance of the inoculated reactors might be related to the potential increase in number of indigenous anaerobic microorganisms of rumen that contributed substantially to degradation of the organic material in the reactor. The data obtained shows a strong influence of the bovine rumen fluid inoculum on anaerobic bio-stabilization of fermentable organic fraction of USW. Martin, (2001) showed, variability and slowness in the rate of solid-state anaerobic digestion may be largely due to inadequate seeding.

Distribution of recirculation leachate on to the solid fraction has been shown as an important factor affecting the degree of substrate degradation. It acts directly on the microorganisms-substrate contact and can favour the substrate rate biodegradation (Castillo et al ., 1995). Martin, (2001) proposed that the leachate recycle might confer no benefit on a well-seeded digester. Its only role may be to compensate for erratic seeding by transporting substrate into clusters of seed particles. Nopharatana et al ., (1997) proposed the directing of leachate to the bed of waste inturn provides moisture, buffering capacity and sources of microorganisms.

2.3.6 Effect of microbial population

Sundh et al., (2003) reported the microbial communities of biogas processes could respond quickly to changes in the feeding rate. The growth rate of acidogens is typically much higher than that of methane formers. Thus the potential advantage of stage separation will depend on whether the turnover rate is limited by the degradation of the readily degradable compounds or by polymer hydrolysis. Hydrolysis, being the first step in overall process, is normally the rate-limiting step of the overall anaerobic digestion process, if the substrate is in solid form. Griffin et al ., (1997) showed that the levels of Methanosaeta sp., decreased rapidly as acetate level build up. Noike et al., (1985) found that the anaerobic degradation of cellulose needs a longer retention time than that needed for methanogenesis. The dominant type of methanogenic bacteria changes as the SRT of the methanogenic reactor changes. Methanosarcina is dominant at short SRTs, while Methanothrix is dominant at long SRTs. M ethanosarcina s hows higher substrate utilization than Methanothrix . Thus the hydrolysis of cellulose limits the rate of anaerobic acidogeneis in an anaerobic digester. Microbial ecosystem needs time to adapt itself to the new substrate (Raynal et al., 1998) inside the digester for degradation.

Ammonia produced in the protein degradation may cause problems in anaerobic digestion as unionized ammonia inhibits anaerobic microorganisms, particularly methanogens. Sterling et al ., (2001) determined the feasibility of monitoring hydrogen gas as an indicator of digester upset resulting from ammonia overloading. This experiment clearly revealed the amount of ammonia nitrogen in the digester feed impacted digester hydrogen production, methane production and VS removal. Small increases in ammonia nitrogen resulted in increased hydrogen and methane production. Large increases caused the inhibition of hydrogen and methane production. Total biogas production reduced to 50% of the original rate with increases in ammonia nitrogen. This is mainly due to the methanogen inhibition metabolism by ammonia, resulting in lower pH. With an insufficient alkalinity, the digester undergoes acidosis, resulting in the cessation of methane production. It has been reported by Van Velsen (1979) that methanogenesis is severely inhibited above 2000mg/L ammoniacal nitrogen (Callaghan, 1999). The problems associated with ammonia inhibition in a high solids anaerobic digestion process can be corrected by one or more of the following methods:

(1). Diluting the contents of the digester to reduce the ammonia concentration in the liquid phase.

(2). Adjusting the C/N ratio of the feedstock and

(3). External ammonia absorption (Kayhanian, 1994).

2.3.8 Pretre a tment methods

Three types of pretreatment are reported in literature, viz., enzymatic hydrolysis, acid hydrolysis, and alkali pretreatment, for improved digestibility of lignin- rich biomass waste. These methods could be used either as a full treatment step for complete hydrolysis to sugars or as an alkali pretreatment step for breaking certain links in the hemicellulose-lignin polymeric system so as to provide increased diffusivity to hydrolytic enzyme. Alkali pretreatment methods have accordingly been adopted by several researchers for achieving increased volatile acid and gas production in anaerobic digesters. Gunaseelan, (1994) reported that the high lignin content of Parthenium was one of the factors accounting for the low methane yield. Alkali pretreatment of Parthenium with NaOH significantly enhanced the methane production and cellulose reduction. Hamzawi et al ., (1998) found that alkaline pretreatment significantly increases the biodegradability of the waste mixture in the co-digestion of sewage sludge and OFUSW.

2.3.9 Influence of bed materials

To maintain a high bacterial concentration in the reactor, immobilization methods of microbial cells onto various supports have been studied (Andersson and Bjornsson, 2002). Chanakya et al ., (1998) envisaged that anaerobically digested herbaceous biomass could be deployed as methanogen support in the anaerobic digestion of several liquid wastes for biogas production. Methanogenic activities measured on such biomass support material exhibited a potential to achieve much higher biogas production. Results clearly indicated that the fermentor functioned well even at 21 ±1ºC with gas production rates up to 3L/L/d and thus appeared to have potential for small-scale high rate biogas production from various combinations of liquid and solid biomass wastes. Yang (2004) reported the effects of bed materials on the performance of methanogenic fluidized bed reactors with acetic acid as a sole organic substrate. Four bed materials such as carbon filter, rock wool , sponge ( loofah- commercial name) and polyurethane foam were evaluated and compared for their methanogenic characteristics and immobilized microbes. Among these, loofah sponge and polyurethane foam were suggested to be suitable for the bed material in anaerobic digestion, since these materials showed good methane yield. This was mainly due to the better performance of porous structure of polyurethane foam and loofah than the fibriform structure of the carbon felt and rock wool. Thus, this result clearly revealed that the material characteristics have some influence on the methane fermentation. Microscopic observations of the immobilized microbes revealed that different bed materials could provide specific conditions for the adherence of distinct microorganisms types. The phylogenetic analysis of 16s rRNA indicated that the major methanogens immobilized on the bed materials were M. formicicum, M. barkeri and M. mazei . In a same way, Baumann, (1997) investigated the anaerobic biodegradability of substances, products and wastewaters using continuous anaerobic fixed bed reactor. Dupla et al ., (1995) investigated the dynamic evaluation of a fixed bed anaerobic digestion process in response to organic overloads and toxicant shock loads using online instrumentation. In case of organic overloads, the fixed bed reactor can be considered as very robust despite very high VFA concentrations. Indeed in both cases (with and without pH regulation in the feeding line), recovery of the process was possible. In addition pH regulation in the feeding wastewater minimized the inhibition of the methanogenic biomass and it helped the overall process to recover faster. When ammonia shock loads were applied, a complete inhibition of the process was expected, but the biofilm protected the microorganisms and no effect could be noticed. Yang et al ., (2004) studied the performance of the fixed bed reactor packed with carbon felt during anaerobic digestion of cellulose. Results showed that biomass distribution in the felt and on the felt surface was high, when compared to the liquid phase, clearly indicated that most of the microbes were immobilized on the carbon felt fixed bed in the reactor. Thus the reactor with the carbon felt bed would be suitable for the efficient anaerobic digestion of cellulose.

2.4 Biological Methane Potential assay (BMP)

BMP assay was developed to determine the ultimate CH 4 yield (B 0 ) of organic substrates and for monitoring anaerobic toxicity. B 0 of a variety of biomass were determined using a modified method of Owen et al ., The BMP is a valuable, quick and inexpensive method for determination of the potential extent and rate of conversion of biomass and wastes to methane. A similar assay has otherwise been named as (ABP) anaerobic biogasification potential (Gunaseelan, 1997). Gunaseelan (2004) evaluated the extents and rates of fruit and vegetable solid waste (FVSW) conversion to methane by means of BMP. The ultimate methane yields of fruits and vegetable feedstock ranged from 0.18 to 0.73 L/gVS and 0.19 to 0.4 L/gVS addition. According to Gunaseelan, (2004) different parts within the same variety showed different yields in orange, pomegranate, grapevine and sapota. Among the FVSW tested in this study, the varieties of mango peels, citrus wastes, pomegranate rotten seeds and pressings exhibited methane yields significantly higher than the cellulose. Most of the FVSW showed methane yields greater than 0.3L/gVS added and thus represent an excellent choice for commercial methane production. In a same way, Chynoweth et al ., (1993) reported the BMP of biomass and waste feedstock. This was evaluated in terms of inoculum, inoculum to feed ratio and particle size for analysis of extent and rate of conversion of biomass and waste feedstock to methane. Results showed that the rumen and sludge inocula exhibited similar solubilization of organic matter, 2:1 inoculum to feed ratio was shown to give maximum conversion rates. Particle size did not influence rate in the range of 1-8 mm. Thus the results of this assay can be used to compare differences in extent and rate of BMP as a function of inoculum, inoculum to feed ratio and particle size.

2.5 Techniques employed for anaerobic digestion

The anaerobic biological treatment of the organic fraction of USW has received attention during the last few years. A conversion of these wastes to methane provides some energy and has a beneficial effect on the environment. The production of methane during the anaerobic digestion of biologically degradable organic matter depends on the amount and kind of material added to the system. So, waste biomass subjected to anaerobic digestion for the above said potential energy value could be performed in various ways. The leading concepts of now -a- days are:

• Single-phase digestion.

• Two phase digestion.

• Co-digestion.

• Dry fermentation.

These four options were effectively utilised for USW treatment. Several studies have been made on the bioconversion of USW by different researchers. For example Mata Alvarez et al ., (1992) carried out experiments on Barcelona's central food market organic wastes, Lane, (1984) on fruit and vegetable wastes, Nand et al ., (1990) on canteen wastes, Cho et al ., (1995) on Korean food wastes and Sharma, (1999) on water hyacinth.

2.5.1 Single Phase Digestion

In the single-phase digestion, the acid forming bacteria and methane forming bacteria exist in the same biological environment (Fig 2.6). That is, complex organics in the wastes first acted upon by the hydrolytic, fermentative, and acidogenic bacteria results in the production of

Fig 2.6. One-step digestion

VFA's, inturn acted upon by the methanogens, results in the production of biogas. Acidogens present at the top portion of biomass bed, rapidly hydrolysing the polymeric substances results in the production of VFA, this inturn get in to contact with those methanogens at the bottom, is possible through leachate recycling process.

2.5.2 Two-phase digestion

In the conventional digesters, the acid forming and methane forming bacteria exists in the same biological environment. In such an environment, the VFA production exceeds than the conversion rates of VFA's to methane. This may results in acids accumulation, leads to pH drop and a consequent inhibition of methanogenesis. To overcome these problems, two-phase anaerobic digestion was suggested (Fig 2.7). This is possible by isolating the two major microbial phases in the two separate reactors (acidogenesis and methanogenesis). This concept was widely used by various scientists to recover the methane from valuable waste resources.

Fig 2.7.Two-step digestion

2.5.3 Dry fermentation

Dry fermentation or high solid digestion came in to light, to overcome the problems created by the slurry phase fermentation. It describes the systems in which the total solids concentration in the digester is about 20-25%. They can show a very high rate of gas production per unit reactor volume. The main advantages of dry fermentation is as follows:

• The addition of water is very limited, decreasing post treatment costs and reactor volume.

• Heating requirements during the process are minimised due to exothermic energy released during anaerobic microbial decomposition.

It would appear that continuous dry fermentation offers the greatest potential for digestion of the organic fraction of solid waste, either on its own or co digestion with other high solids organic wastes.

An interesting option for improving yields of anaerobic digestion of solid wastes is co-digestion. In this the use of a co-substrate is employed, which in most cases improves the biogas, yields due to positive synergisms established in the digestion medium and the supply of missing nutrients by the co-substrates. More works have been done on biogas by utilising this property (Mata-Alvarez et al ., 2000). For this property, it is important to choose the appropriate criterion for assessing the “optimum mix” of the different mixtures of wastes. It must also be recognized that, with a practical co digestion facility, it might not be possible always to operate with the optimum blend of wastes as long term storage would not really be a sensible consideration, particularly in countries with high ambient temperature (Misi et al ., 2001). For instance in North America, this option has been examined in a study evaluating the technical feasibility of the anaerobic co-digestion process for typical solid wastes (Hamzawi et al., 1998). Using biological activity tests, an optimal mixture, for biogas production was identified as 25% OFUSW and 75% sewage sludge (65% raw primary sludge, 35% thickened activated sludge (TWAS)). Also based on the rate of biogas production, the most anaerobically biodegradable components of OFUSW were paper and grass. TWAS and newspaper were found to be the least biodegradable components. The authors also developed empirical models based on alkaline dose, total solids concentration in feed and particle size, biogas production and removal of TS and VS. All five experimental factors were found to be significant with respect to the response variables studied. Callaghan et al ., (1999) tested the several mixtures of cattle slurries with a range of different wastes, allowing them to digest in 1L-batch digesters. The criteria for judging the success of a co-digestion were VS reduction, total methane production and methane yield. In terms of the VS reductions (%), there was little difference between the various digestions. In terms of the cumulative methane production, the co-digestions with fruit a vegetable wastes, fish offal and dissolved air floatation sludge were more effective than the digestion with cattle slurry alone. Compared with their control (cattle slurry alone), both co-digestions with poultry manure (7.5 and 15%TS) gave higher cumulative productions of methane, and the system with the lower concentration of poultry manure gave a higher specific methane yield.

2.5.5 Sources of methane chosen for the study

From the above-mentioned solid wastes a wide range of biomass wastes have been considered as potential sources for methane production (Fig 2.8).

Fig 2.8. Selected types of methane yielding wastes

2.5.5.1. Organic fraction of USW

The composition of USW varies from place to place, due to its heterogeneous (different) nature. The composition of USW is affected by various factors, including regional differences, climate, and extent of recycling, collection frequency, season, cultural practices, as well as changes in technology. Reserved form of chemical energy in these wastes can be renewed by means of biogas production. Rodriguez et al ., (2000) carried out the pilot plant studies to observe the mechanism of anaerobic digestion of USW and also to study the behavior of a sanitary landfill under controlled conditions leads to the optimization of the operating mode of a sanitary landfill deposit by reducing the pollution load of the leachate formed and by increasing the production of biogas. Chanakya et al ., (1992) utilized major part of SW for biogas production. The digester employed in this study constitutes solid phase acidogenic digester and up flow bed methanogenic digester packed with acid washed granite chips, with the capacity of 2L and 0.5L respectively. Feed rates adopted for this study was 1g TS, increased up to 2g TS /week for 63 days and 102 days respectively. The total 19g TS of urban garbage samples gave rose to 6.37gVFA and 1.73L gas production, showing the utilization efficiency of 33.5%. Thus the major part of OFUSW gave good yield of methane, if it is properly and biologically converted to methane. Vieitez, (1999), subjected finely chopped pieces of MSW to the digestion. The digester employed in this study constitutes cylindrical, jacketed, cone bottomed solid bed reactor with the volume of 14L capacity gave the bed volume of 12L and methane phase reactor filled with plastic rings gave the void volume of 90% and culture volume of 8L. 1.227 kg of dry chopped MSW compacted to a density of 160 kgm -3 was adopted as a loading rate. 7.4L of inoculum was used to initiate the digestion, includes 3L of digested sludge with 4.4L of tap water, results in the production of 900ml leachate in turn contains 13g/L of VFA, contributes the specific methane yield of 0.12 SCM/kg of VS showing conversion efficiency of 40%. Hamzawi (1998) evaluated the technical feasibility of the anaerobic co-digestion of sewage sludge with the organic fraction municipal solid waste. Using biological activity tests, an optimal mixture was identified with 25% organic fraction of municipal solid waste and 75% sewage sludge based on biogas production. It was found that the alkaline pre-treatment increased the biodegradability of the sewage sludge/OFUSW mixture over that of the untreated control. Thermo chemically pre-treated feedstocks inhibited anaerobic biodegradability as compared to the control, whereas the anaerobic biodegradability of thermally pre-treated feed was not found to be significantly different from that of the control. The empirical models were developed based on alkaline dose, total solids concentration in feed and particle size, biogas production and removal of TS and VS. All five experimental factors were found to be significant with respect to the response variables studied (Hamzawi et al ., 1998). Rao et al. , (2000) concluded that the municipal garbage is a high potential bioenergy source and it can be effectively utilized for biomethanation process. Results showed that biogas yield of 0.661m 3 /kg VS, indicating the high biodegradability of the feed. This yield was found to be 2.5 times the yield obtained from the cattle dung, indicating that anaerobic conversion of municipal garbage to biogas is a suitable option for commercial energy production.

2.5.5.2. Fruit and vegetable solid wastes

These wastes are characterized by high percentages of moisture ( > 80 %) and VS ( > 95 %) and have a very high biodegradability. The methane yield of FVSW is very high. Lane, (1984) carried out some trials to determine the long-term stability of digestions fed with fruit and vegetable wastes. It was found that recovery of settled solids from the discharged digester effluents and their return to the digester enables 88-96% VS removal, provided adequate alkalinity levels are maintained. For balanced digestion, alkalinity (mg/L) of 0.7 X volatile fatty acids (VFA, mg/L) is required and it should not be less than 1500. The performance of digestion of asparagus waste was stable at OLR of 4.2 kg VS m -3 d -1 with 90% removal of VS. Bouallagui et al ., (2003) evaluated the performance of tubular digesters at higher loading rates, in order to establish conditions for optimal conversion of FVW into biogas. The work was carried out in semi-continuously mixed mesophilic tubular digesters. The overall performance of the reactor was depressed by changing the feed concentration from 8%-10%TS. The most significant factor of the tubular reactor is its ability to separate acidogenesis and methanogenesis longitudinally down the reactor, allowing the reactor to behave as a two-phase system. In this digester FVW could be treated anaerobically with a high stability, high depurination rate and energy recovery with a good process economy. Viturtia et al ., (1995) evaluated the two-phase continuous anaerobic digestion of these feedstocks in the mesophilic range using a hybrid up flow anaerobic sludge bed anaerobic filter reactor. In this study phase separation has been achieved without difficulty. This was very clear from the values of pH and VFA concentration in both hydrolyser and methanizer. When the systems were operated at hydrolyser and methanizer HRT of 2.6 and 1 day respectively, methane yield as high as 0.51m 3 kg -1 VS was achieved (Viturtia, 1995). Hence two-phase digestion was also possible for the conversion of these wastes in to biogas was clearly depicted from the results. High biogas yields are obtained from digesting a mixture of fruit and vegetable wastes in a batch two-phase system with digested pig manure as inoculum, results in maximum gas production. Also evaluated, that the one phase system seems to be more appropriate for this type of waste (Mata-Alvarez et al., 1993). Thus it is very clear from the above study, that the hydrolytic step was affected by OLR, since at high organic loads hydrolysis does not seem to be very effective. Furthermore, at higher loads, more methanization takes place in the hydrolyser than in methanizer, because VFA are in a lower concentration and, thus phase separation is not so effective. At low organic loads, VFA concentrations are poor, because they are immediately optimised and the yields per kg VS are high. Thus to upgrade yields in a two-phase system, more investigations would be needed concerning the system set-up, the control of pH in both reactor, etc., in order to optimise conditions in both the hydrolyser and methanizer. Thus the one phase system would be the best choice. Since it is simpler, can be applied successfully to the treatment of this type of waste without any type of control action. As a solution to the problem of ammonia inhibition during the anaerobic digestion of chicken manure, it has been proposed that co-digestion with cattle slurry could be a possible disposal route (Callaghan et al ., 2002). In fact in his previous study, co-digestions were used, as a screening trial to determine which wastes could be best with cattle slurry. This showed that chicken manure, fish offal and FVW were the most promising combinations. Also, tested several mixtures of cattle slurries with a range of different wastes, allowing them to digest in 1-L digesters. The criteria for judging the success of a co-digestion were VS reduction, total methane production and methane yield. When fruit and vegetable solid waste was co-digested with cattle slurry with the feed containing 30% or more FVW, high concentrations of VFA's were produced. Despite this, mixtures of CS and FVW, gave a good co-digestion in terms of methane yield, but the VS reduction decreased slightly. Chicken manure was not as successful as a co-digestate. As the amount of CM in the feed and the organic loading was increased, the VS reduction deteriorated and the methane yield decreased. This appeared to be due to the concentrations of free ammonia present in the liquors. Lomas et al ., (1999) also observed the same kind of process inhibition by ammonia.

2.5.5.3. Leaves

Chanakya et al., (1993) evaluated the solid phase fermentation process to overcome problems in conventional slurry based reactors. Their experiment demonstrated the feasibility of solid waste conversion of biomass to biogas. In digesters that were fed with intact, untreated leafy or USW biomass feedstock in a weekly fed batch mode without spent feed removal, acidogenesis and methanogenesis were shown to occur in different layers of the decomposing biomass bed.

2.5.5.4Grasses

Zhang, (1999) studied the anaerobic phased solids digester system for the conversion of rice straw to biogas. Ligno-cellulosic rice straw digestion is difficult to degrade biologically. Hence different pre-treatment methods such as physical, thermal and chemical treatment on the digestion of rice straw were investigated. Results clearly depict that the combination of grinding, heating and ammonia treatment resulted in the higher biogas yield. Thus, it was very clear that the pre-treatment has some significant role on the digestibility of the straw. Lawn grass-major fraction of USW was chosen and subjected to this digestion (Yu et al ., 2002). The digester employed in this study was 8m 3 solid phase reactor (harbouring 155 kg of feedstock) coupled with methane phase reactor consisting of inert commercial packing media used to facilitate the bacterial attachment and growth. This package gives the total porosity of 190 L/Column, operated like up flow anaerobic filter. Maximum loading rate in this digester was determined to be 2.7 kg of COD/m 3 of UAF per day. Yu et al ., (2002) also studied the effects of temperature on the gasification efficiency by using heated UAF in one of the reactor. Higher gas production was reported in the heated UAF was due to the higher COD conversion (35.6 kg of COD compared to the 26.4 kg of COD conversion in ambient UAF column). This COD conversion contributes 0.344 m 3 and 0.339 m 3 of CH4 /kg of COD removed. Hence it is very clear that one kg of grass showed the yield of 0.15 m 3 of methane (Yu et al. , 2002).

2.5.5.5 Terrestrial and aquatic weeds

The use of weed plants, as a potential source of biomass is a rather recent concept. Aquatic macrophytes have been the subject of great interest for the past few years, because of their potential uses in wastewater treatment. The concept of using aquatic plants for water treatment and the harvested biomass as an energy source is gaining attention throughout the world. Eichornia crassipes , Water hyacinth, until 1940's and 50's was considered an obnoxious weed clogging up agricultural canal systems, dammed streams and encouraging mosquito breeding (Gopalakrishna, 1989). The prolific growth of water hyacinth and the ease of harvest techniques make it a suitable feedstock for biological conversion to methane. It can be utilised in both the fresh and dried forms serves as an alternative feedstock for the biogas production and can also be employed for phytoremediation purpose (Singhal et al ., 2003).

These non-conventional crops on wastelands and aquatic lands can be considered as potential biomass and used efficiently to recover the reserved form of energy, because:

• Weeds have ability to trap a significant amount of solar energy.

• Weeds are capable of growing on soils generally unsuitable for conventional crop production.

• The genetic base of weeds is such that many can grow under a wide range of cultural and climatic conditions.

• Weeds grow in natural stands without inputs and irrigation.

Hence the large-scale utilisation is one of the best strategies for weed management.

a. Terrestrial weeds

Parthenium hysterophorus, paper mulberry are some of the weeds used and studied as sources for methane production. Gunaseelan (1994) reported that anaerobic digestion of mixtures of chicken manure and Parthenium (flowering stage) enhanced methane production in batch digesters. Anaerobic digestion of Parthenium in CSTR at 30 ° C, 10 day HRT and 4.13 kg VS m 3 d -1 produced methane yield of 0.11 m 3 kg -1 VS added and volumetric methane productivity of 0.46m3 gas m -3 d -1 . Results on pre-treatment showed greater than 95% increase in methane production from NaOH treated Parthenium than untreated Parthenium.

b. Aquatic weeds

Chanakya et al ., (1992) utilised water hyacinth for biogas production. The total 19g TS of fresh and dry water hyacinth gave rose to 3.15g VFA, 4.02g, inturn corresponds to 1.64L, 1.63L gas production, showing the utilisation efficiency of 16.6%, 21% respectively. The ultimate methane yields from water hyacinth, based on BMP assay, showed that CH 4 yields were higher in shoots than roots (Shiralipour et al ., 1984). The ultimate methane yield from water hyacinth, based on ABP assay was 0.34m 3 kg-1 VS added. Alkaline treatment with 50% NaOH increased the ultimate biodegradability by approximately 15%, and neither particle size reduction nor steam treatment exhibited any effects (Gunaseelan, 1997).

2.6 Bio-digesters

The bio-digester is a physical structure, commonly known as the biogas plant. Since various chemical and microbiological reactions take place in the bio-digester, it is also known as bioreactor or anaerobic reactor. The main function of this structure is to provide anaerobic condition within it. As a chamber, it should be air and watertight. It can be made of various construction materials and in different shape and size. Construction of this structure forms a major part of the investment cost. Some of the commonly used designs are discussed below.

Experiment on biogas technology in India began in 1937. In 1956, Jashubhai J Patel developed a design of floating drum biogas plant popularly known as Gobar Gas plant. In 1962, Patel's design was approved by the Khadi and Village Industries Commission (KVIC) of India and this design soon became popular in India and the world. In this design, the digester chamber is made of brick masonry in cement mortar. A mild steel drum is placed on top of the digester to collect the biogas produced from the digester. Thus, there are two separate structures for gas production and collection. With the introduction of fixed dome Chinese model plant, the floating drum plants became obsolete because of comparatively high investment and maintenance cost along with other design weaknesses.

2.6.2 Fixed dome digester

Fixed dome Chinese model biogas plant (also called drum less digester) was built in China as early as 1936. It consists of an underground brick masonry compartment (fermentation chamber) with a dome on the top for gas storage. In this design, the fermentation chamber and gasholder are combined as one unit. This design eliminates the use of costlier mild steel gasholder, which is susceptible to corrosion. The life of fixed dome type plant is longer (from 20 to 50 years) compared to KVIC plant. Based on the principles of fixed dome model from China, Gobar Gas and Agricultural Equipment Development Company (GGC) of Nepal has developed a design and has been popularizing it since the last 17 years. The concrete dome is the main characteristic of GGC design.

2.6.3 Deenbandhu model

In an effort to further bring down the investment cost, Deenbandhu model was put forth in 1984 by the Action for Food Production (AFPRO), New Delhi. In India, this model proved 30% cheaper than Janata Model (also developed in India) that is the first fixed dome plant based on Chinese technology. It also proved to be about 45% cheaper than a KVIC plant of comparable size. Deenbandhu plants are made entirely of brick masonry work with a spherical shaped gasholder at the top and a concave bottom. Preliminary studies carried out by BSP did not find any significant difference in the investment costs of GGC and the Deenbandhu design plants. Recently, Environmental Protection and Social Development Association (EPA), a NGO, has constructed modified Deenbandhu design plants in Bardiya district, which is also approved by Biogas Support Programme (BSP). In addition to above designs developed particularly for household use in developing countries, there are other designs suitable for adoption in other specific conditions.

This design was developed in 1960s in Taiwan. It consists of a long cylinder made of PVC or red mud plastic. The bag digester was developed to solve the problems experienced with brick and metal digesters. A PVC bag digester was tested in Nepal by GGC at Butwal from April to June 1986. The study concluded that the plastic bag bio-digester could be successful only if PVC bag is easily available, pressure inside the digester is increased and welding facilities are easily available (Biogas Newsletter, No. 23, 1986). Such conditions are difficult to meet in most of the rural areas in developing countries.

This type of digester was developed in the 1950's to use relatively dilute and soluble waste water with low level of suspended solids. It is one of the earliest and simplest types of design developed to reduce the reactor volume. It consists of a column filled with a packing medium. A great variety of non-biodegradable materials have been used as packing media for anaerobic filter reactors such as stones, plastic, coral, mussel shells, reeds, and bamboo rings. The methane forming bacteria form a film on the large surface of the packing medium and are not carried out of the digester with the effluent. For this reason, these reactors are also known as "fixed film" or "retained film" digesters (Bioenergy Systems Report, 1984).

2.6.6 Up-flow anaerobic sludge blanket

This UASB design was developed in 1980 in the Netherlands. It is similar to the anaerobic filter in that it involves a high concentration of immobilized bacteria in the reactor. However, the UASB reactors contain no packing medium, instead, the methane forming bacteria are concentrated in the dense granules of sludge blanket which covers the lower part of the reactor. The feed liquid enters from the bottom of the reactor and biogas is produced while liquid flows up through the sludge blanket. Many full-scale UASB plants are in operation in Europe using waste water from sugar beet processing and other dilute wastes that contain mainly soluble carbohydrates (Bioenergy Systems Report, 1984). There are also other designs of anaerobic reactors, which are of less interest due to their limited utility. Reduction in investment cost using alternative construction materials has been one of the main driving forces in the development of new designs. In an effort to achieve this objective, use of bamboo, plastics and other such cheap construction materials have also been tried with varying degree of success (Cortsen, Lassen and Neilsen, 1995; Beteta, 1995). However, all such reported success stories are yet to take the form of implementation programmes in a mass scale.

2.7 Current status: Need for new biogas producing technologies

Variations in reactor design, operating conditions and feed composition will result in changes within the microbial populations present in the system. Further insight into these changes is not only beneficial from a microbiological point of view but also in the development of novel reactor designs and modes of operation. In addition, Wase (1984) reported that the choice of the digester is therefore considered in relation to the waste itself, results in the possibilities of increased use of anaerobic digestion as a treatment process arise from the introduction of improved reactor designs. The digester performance is highly sensitive to the quality of the feed of wastes, then yield and kinetics of the biological reaction involved in anaerobic digestion being strongly dependent upon waste composition (Archana et al ., 1999). There are no simple biogas producing technologies capable of continuous operation using solid wastes without investing substantial capital and energy in to slurrification. Such slurrification does not suit for the Indian context. The CST (IISc campus) has addressed this problem and developed the plug flow and solid state stratified bed fermenters for the effective anaerobic treatment:

2.7.1 Solid state stratified bed reactor (SSB)

SSB reactor came in to existence to overcome the problems related to floating, pre-treatment and feedstock addition. By virtue of its ability to accept fresh or dried feedstock without serious operation problems makes it an attractive process option. The SSB digesters permitted the use of untreated, large sized biomass feedstock and avoided particle size reduction. Simple reactor design constitutes the digester, which inturn is connected to the gasholder. A two-reactor configuration may be simplified into a single reactor configuration when methanogen rich biomass bed is placed in the lower part of the reactor and operated in the following manner. When a small quantity of recycled digester liquid was sprinkled over the decomposing biomass bed in solid-state stratified bed digesters, VFA rich pockets were dissipated. When these VFAs reach the lower part of the biomass bed intensely colonised by methanogens, they are quickly converted to biogas (Chanakya et al ., 1995). Therefore it is possible to design and operate a two-phase system within a single vessel functioning as a stratified bed reactor. This greatly simplifies design and operation for small-scale rural use. In such a process, fresh feedstock needs to be introduced on top of the bed and spent biomass needs to be taken out from below in order to permit continuous operation. Such a fermentation process also overcomes another problem, namely, the need to add biomass feedstock without concomitant introduction of air. Untreated and intact biomass feedstock can thus be introduced through a hatch at the top of the biomass bed being predominantly acidogenic; the overall process is not affected (Chanakya et al ., 1995). This is because the methanogens are colonised far below in the decomposed bed and oxygen (in air) introduced at the top does not reach these lower layers. This therefore greatly simplifies the feedstock addition and fermenter design. It is also not necessary to maintain a large liquid phase in the reactor because only an equivalent of 5-10% of the fermenter volume needs to be used as a liquid phase, which is continuously recycled.

The solids retention time in such fermenters are thus governed by:

• The duration for which there is a VFA flux (rapid acidogenic stage).

• The rate of compaction of biomass feedstock.

• The rate and extent to which methanogens colonize on decomposed biomass.

• The quantity of methanogen colonised decomposed biomass to be retained for converting the VFA fluxes to biogas.

2.7.2 Plug flow bioreactor

The plug flow digester is similar to the bag digester. It consists of a trench (trench length has to be considerably greater than the width and depth) lined with concrete or an impermeable membrane. The reactor is covered with either a flexible cover gasholder anchored to the ground, concrete or galvanized iron (GI) top.

In the plug flow digester, a volume of the medium with a suitable inoculum enters at one end of the tube and, if the rate of passage of the medium is correct, by the time the medium reaches the other end, denotes that the digestion is completed. For continuous operation, some of the digested effluent flowing from the end of the tube is separated and returned to the influent substrate. Rapid initial decomposition of the feed to volatile fatty acids takes place within 3-5 days of feeding. This takes place when the biomass is still forcibly submerged in water. As a result proper diffusion of VFA's is obtained which prevents their accumulation. When the biomass is still under water and the rapid VFA producing constituents are removed from them, methanogenic bacteria colonize on it and gas is produced from itself. The gas bubbles adhere to the biomass because of which its buoyancy increases and it soon begins to float. At this stage even though biomass remains a float there is adequate methanogenic activity and VFA produced is converted to biogas without facing VFA over-production and subsequent souring. Towards the end of 30-40 days SRT, much of the VS are decomposed but the feedstock is usually still float, albeit to a lesser degree and is manually removed to enable continuous operation.

The Valorga technology was developed initially in France and later by Steinmuller Valorga Sarl, a subsidiary of the German company Steinmuller Rompf Wassertechnik GmbH. The process was initially designed to treat organic MSW and was later adapted to the treatment of mixed MSW, biowaste (source separated household waste), and grey waste (organic residual fraction after biowaste collection). The Valorga process plant consists of essentially six units: waste reception and preparation unit, AD, compost curing, biogas utilization, air treatment, and an optional water treatment unit (when effluent is not treated in municipal wastewater treatment plant). The reception unit has a scale for weighing the trucks bringing in the organic materials. The waste is unloaded in a closed pit equipped with a foul air collection system. The feed material passes through an electromechanical system, designed according to the waste to be treated, that includes plastic bag opening and size reduction equipment. The waste is then conveyed and fed continuously to the AD unit. In the AD unit, the waste is mixed with re-circulated leachate into a thick sludge of about 20-35% solids content, depending on the type of waste. Therefore, the water requirement is minimal. The digester operates either in the mesophilic range or the thermophilic range. The Valorga digesters are concrete vertical cylinders of about 20 meters height and 10 meters internal diameter. They are designed so as to maintain plug flow through the reactor. They are equipped with a vertical partition in the center that extends over 2/3 of the diameter and over the full height of the reactor. This inner partition minimizes shortcircuiting of the sludge and ensures plug flow through the entire volume of the reactor. The orifices for introducing feed and removing digestate are located on either side of the inner wall. Mixing of the fermenting material is provided by a pneumatic system i.e. biogas at high pressure is injected through orifices at the bottom of the reactor and the energy of the rising bubbles serves to mix the sludge. There are no mechanical parts and maintenance consists of periodic cleaning of the nozzles at the bottom of the digester. The digested material exiting the reactor goes through a filter press that separates the compost material from the leachate solution. The leachate is reused for diluting incoming waste and any excess is transferred to the water treatment unit or the municipal sewage network. The filter cake is transferred to composting piles where it is subjected to curing in a closed building for about two weeks. Stones and other inert materials are removed. The compost product is considered to be of high quality and is sold as soil conditioner. The biogas produced is used to generate electricity and steam or is fed to the city gas network. The biofilters and the water treatment facilities ensure that the Valorga plants control all air and water emissions and meet local regulations (Source: Verma, 2002). Laclos et al ., (1997) showed that the valorga plant in Tilburg (methane yield-210 to 290 m 3 STP/ Mg of VS) clearly demonstrate that anaerobic digestion can be considered as a reliable industrial process for the treatment of organic solid waste.