|

Materials and Methods

Case Study:

Bioethanol from Enteromorpha intestinalis

The above-mentioned challenges are addressed in this case study,

which involves bioethanol production from green macroalgae; Enteromorpha

(Ulva) intestinalis belonging to Ulvaceae family.

They grow profusely and occupy intertidal zones under favourable

nutrient, salinity, light and temperature condition. E.

intestinalis is composed of 40.1% total carbohydrate,

20.4% Protein, 2.8% Lipid. Elemental analysis such as carbon

33%, nitrogen 4.36% and hydrogen 6.44% were recorded.

Biochemical composition of E. intestinalis is

comparable to earlier studies Cho et al., (2013) recorded 42.8%

carbohydrate, 31.6% crude protein and 1.3% crude lipid.

Bioethanol prospects from E. intestinalis is elucidated

in this section (Fig 6).

Fig. 6. Bioethanol production from green macroalgae

Enteromorpha intestinalis

Dilute acid hydrolysis of E. intestinalis at 0.7 N

H2SO4, 5% substrate concentration,

121oC for 45 min produced 239.94±1.3 mg/g of reducing

sugar. Enzyme extracted from marine bacteria Vibrio

parahaemolyticus (Hebbale et al., 2019). Pretreated

biomass of E. intestinalis subjected to enzyme

saccharification at pH 6, 50oC for 24 and obtained

reducing sugar of 289.89±2.4 mg/g of reducing sugar. Acid

pretreated macroalgal biomass was subjected to enzyme hydrolysis

using enzyme and incubated for 24 h, 1.2-fold increase in

reducing sugar was observed in E. intestinalis when

compared to dilute acid pretreatment. Scanning electron

micrographs of hydrolysed biomass indicates that the dilute acid

pretreatment prior to enzyme saccharification is a prerequisite

as it loosens the rugged surface of the biomass increasing the

surface area and exposing more of internal cellulose as seen in

Fig 7.

Fig 7. Scanning electron micrograph

of E.intestinalis illustrating

ultrastructural variations in the feedstock after

pretreatment and saccharification.

Acid hydrolysate obtained subjected to SHF using Pichia

kudriavzevii yeast strain isolated from Toddy juice at

35oC, 100 rpm for 24 h. Ethanol of 0.16 g with 51.8%

efficiency obtained. Pretreated biomass subjected to SSF process

using enzyme from Vibrio parahaemolyticus and Pichia

kudriavzevii yeast at 55oC,100 rpm for 24 h.

Ethanol of 0.10 g obtained with 65.1% efficiency. SSF exhibited

higher efficiency than SHF process.

Mass-energy balance was carried for analysing ethanol production

from P. kudriavzevii (TY) and the sugars obtained from

both SHF and SSF processes. Results obtained were extrapolated

to 1kg to make the study more comprehensive. Fermentation of

E. intestinalis in SHF process, obtained 23.9 g/kg

(30.4 ml/kg) ethanol with 55.9% conversion efficiency whereas in

SSF process 28.9 g/kg (35.8 ml/kg) ethanol with 83.9% conversion

efficiency was obtained (Table 6). Ethanol from SSF was

estimated 1.18-fold higher than the ethanol obtained from SHF

process indicating better efficiency. Similar results were

obtained for fermentation of E. intestinalis using S.

cerevisiae. SSF process achieved 30.5% efficiency when

compared to SHF (26.9%) process indicating better performance

regarding fermentation yield and faster process. Similar

mass-energy balance study was reported with the various

feedstock, 1kg of Saccharina japonica biomass yielded

23.1g (29.2 ml) of ethanol using SSF process achieving

conversion efficiency of 67.41% (Lee et al., 2013). Fermentation

of 1kg G, verrucosa produced 38g (48.1 ml) of ethanol

from SSF process achieving fermentation efficiency of 86% (Kumar

et al., 2013). Acid pretreatment of 1kg K. alvarezii followed

by detoxification produced 80g of galactose which was fermented

(SSF) to produce 43.7g (55.3 ml) of ethanol achieving 78.5%

conversion efficiency (Hargreaves et al., 2013). Fermentation of

1kg of switchgrass (second generation feedstock) produced 178.4

g (226.1 ml) of ethanol using SHF process, while SSF process

produced 183.5g (232.5 ml) of ethanol, but achieved lower

conversion efficiency which is attributed to the presence of

insoluble lignin in the biomass, that was treated using Ammonium

Fibre Expansion (AFEX) (Jin et al., 2010). Higher ethanol in SSF

process is due to the rapid consumption of glucose by yeast as

they were produced during enzyme hydrolysis (Xiao et al., 2004).

Acid hydrolysis of 1 kg of Lantana camara followed by

delignification, enzymatic hydrolysis of the biomass and

fermentation yielded 148.14 g (187.7 ml) of ethanol, whereas,

fermentation of pentose rich hydrolysate yielded 51.6 g (65.3

ml) of ethanol (Kuhad et al., 2010). Bagasse pith (1 kg)

(second-generation feedstock) produced 46.2 g (58.5 ml) and 66.4

g (84.1 ml) of ethanol by SHF and SSF process respectively. In

this study, commercial enzyme cellulase and β-glucosidase were

employed for enzyme hydrolysis and fermentation was carried

using P. stipitis JCM 10742 (Sritrakul et al., 2017).

Notable advantages were observed from SSF over SHF process, as

SSF process is amenable to enzyme hydrolysis with the rapid

ethanol production and occurrs in a single reactor, thereby

reducing the operation and investment costs for setting up a

biorefinery.

Ethanol production from macroalgal biomass results in large

quantity of spent biomass or waste products that are generally

disposed. High value products are created from these wastes

through the concept of biorefinery which aims to achieve no

waste flow resulting in economic and environmental benefits

(Balina et al., 2017).

Table 6. Ethanol

production from different macroalgal feedstock

(expressed in L per 100kg of biomass) |

Feedstock

|

Ethanol L per 100kg

|

|

1st generation feedstock

|

Corn grain |

35.6 |

Sorghum |

35 |

Cassava |

17 |

2nd generation feedstock

|

Rice |

43 |

Wheat |

34 |

Grapes |

13 |

Sugarcane bagasse |

76 |

|

Switchgrass |

22.6 |

3rd generation feedstock

|

Gracilaria verrucosa |

4.7 |

Ulva fasciata |

11.7 |

Kappaphycus alvarezii |

1.7-2.4 |

Gracilaria corticata |

2.6 |

Laminaria digitata |

26.2 |

Gelidium amnasii |

1.62 |

Enteromorpha intestinalis* |

3.55 |

Ulva lactuca* |

5.58 |

Palmaria palmata |

1.6 |

Ulva pertusa |

11.6 |

Lamanaria japonica |

36.8 |

Gelidium elegans |

23.2 |

Gelidium amansii |

8.8 |

Sargassum sp. |

28.70 |

*Present study |

|

|

Economic

Prospects of Macroalgae- Biorefinery

Seaweeds were mostly restricted to domestic purposes such as food

and feed, preparation of industrial gels, medicinal uses such as

Laminaria sp. for dilation of cervix in difficult

childbirth, Gelidium sp. used for intestinal

afflictions etc. In recent times, macroalgal biomass are

cultivated on largescale for production of more valuable

commodity than food and feeds. These include, extraction of

polysaccharides for agronomic applications, cosmeceuticals,

nutraceuticals, pharmaceuticals, and bioenergy. Seaweed

biorefinery approach extracts most valuable components from the

macroalgal biomass without altering the residue for commodity

purposes such as food, feed, fertilizers etc.(Balina et al.,

2017; Buschmann et al., 2017).

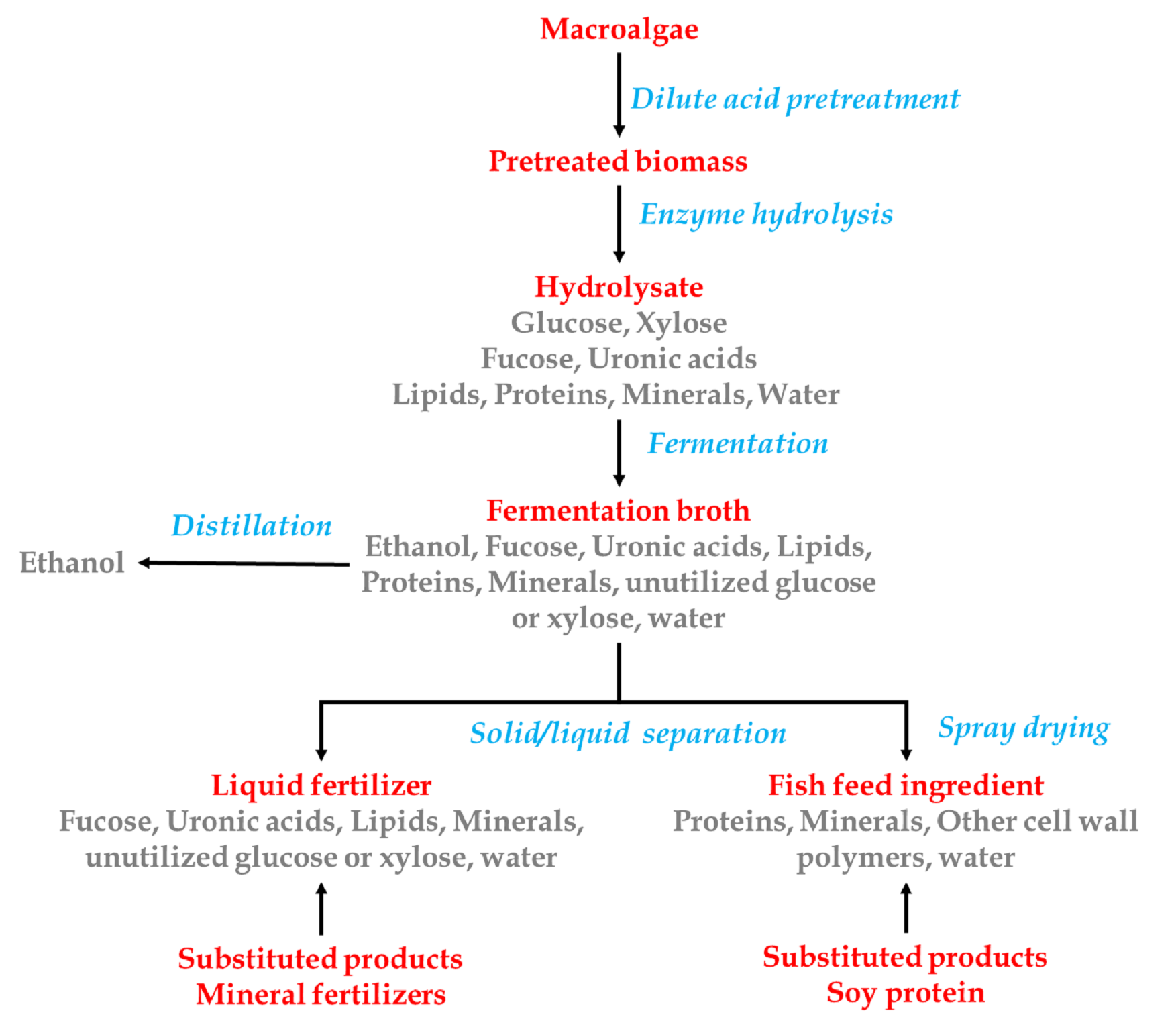

Macroalgae is subjected to dilute-acid pretreatment and

pretreated biomass is hydrolysed using enzyme. Enzyme

hydrolysate is fermented to produce ethanol. Solid/liquid

separation is carried out for the fermentation broth. The liquid

fractions are rich in lipid, minerals and other unutilized

sugars and are used as liquid fertilizers, which substitutes the

conventional mineral fertilizers. The solid fraction is spray

dried and rich with protein and minerals and is being used as

fish feed, which serves as a substitute for soy protein (Fig 7).

Selection of appropriate macroalgal feedstock accumulating

higher carbohydrate fractions and nutrients can lower the

CO2 level and provide climate change and marine

eutrophication mitigation services (Seghetta et al., 2016).

Fig

7. Seaweed biorefinery with probable constituents

Fatty acids content in the dried and

canned macroalgae are of linear structures and are major sources

of essential fatty acids such as palmitic acid and ω-3, 6 and 9.

Agar from G. edulis, G. acerosa and

Gracilaria sp. are extracted by boiling the seaweed and

extract is filtered, freeze thawed and dried in sun and market

as powder (Kaladharan and Kaliaperumal, 1999). Macrocystis

pyrifera was harvested for production of acetone and

potash (Roesijadi et al., 2010). Macroalgal biomass is composed

of high amount of water-soluble potash, which is readily

absorbed by the plants. Composting of seaweed along with shark

liver sediments and fish offal (15:4:3 by weight) fetches high

manure value with 2.4% N, 0.7% P and 3.5 % potash (Chennubhotla

et al., 1981). Macroalgal biomass are regarded as ‘super foods’

for being rich in vitamins B12, A and iodine. Seaweed meal

incorporated in poultry and animal feed increased the iodine

content of the eggs and milk production in dairy cows (Hebbale

et al., 2017; Holdt and Kraan, 2011; Torres et al., 2019).

Discarded waste of algin extracted macroalgal biomass is

estimated to contain 93-94% of iodine (Torres et al., 2019).

Extracted protein fraction from Ulva increase illeal

digestibility and rumen fermentation (Baeyens et al., 2015;

Bikker et al., 2016). Apart from whole seaweed, residue obtained

from industries; floating residues, spent biomass serves as

feedstock for bioethanol production (Sudhakar et al., 2016).

Therefore biorefinery approach is sustainable and

environmentally friendly as it reduces the burden on

environment.

Fatty acids content in the dried and canned macroalgae are of

linear structures and are major sources of essential fatty acids

such as palmitic acid and ω-3, 6 and 9. Agar from G. edulis,

G. acerosa and Gracilaria sp. are extracted by

boiling the seaweed and extract is filtered, freeze thawed and

dried in sun and market as powder (Kaladharan and Kaliaperumal,

1999). Macrocystis pyrifera was harvested for

production of acetone and potash (Roesijadi et al., 2010).

Macroalgal biomass is composed of high amount of water-soluble

potash, which is readily absorbed by the plants. Composting of

seaweed along with shark liver sediments and fish offal (15:4:3

by weight) fetches high manure value with 2.4% N, 0.7% P and 3.5

% potash (Chennubhotla et al., 1981). Macroalgal biomass are

regarded as ‘super foods’ for being rich in vitamins B12, A and

iodine. Seaweed meal incorporated in poultry and animal feed

increased the iodine content of the eggs and milk production in

dairy cows (Hebbale et al., 2017; Holdt and Kraan, 2011; Torres

et al., 2019). Discarded waste of algin extracted macroalgal

biomass is estimated to contain 93-94% of iodine (Torres et al.,

2019). Extracted protein fraction from Ulva increase

illeal digestibility and rumen fermentation (Baeyens et al.,

2015; Bikker et al., 2016). Apart from whole seaweed, residue

obtained from industries; floating residues, spent biomass

serves as feedstock for bioethanol production (Sudhakar et al.,

2016). Therefore biorefinery approach is sustainable and

environmentally friendly as it reduces the burden on

environment.

Scope for further research

Marine macroalgae have been explored worldwide for various

application owing to their ability to accumulate large

concentration of biomolecules (especially carbohydrates), which

serve as raw material for bioethanol production and other

value-added products. Bioprocess of bioethanol production

involves three major steps; dilute acid pretreatment, enzyme

saccharification and fermentation. The major future prospective

for bioethanol production from macroalgal biomass includes (i)

exploring enzymes having higher catalytic activity and stability

at extreme conditions (ii) yeast microorganisms able to ferment

broad range of sugars (iii) improved ethanol yield by process

optimization (iv) Consolidated bioprocess involving cellulolytic

yeast to hydrolyse cellulose as well as fermented subsequent

glucose released during hydrolysis to ethanol. Biorefinery

approach can be realised only with sufficient quantities of

biomass. Largescale cultivation of macroalgae in open ocean is

results is disease outbreaks and destruction of habitat (killing

endemic corals) (Bindu & Levine, 2011; Patterson et al.,

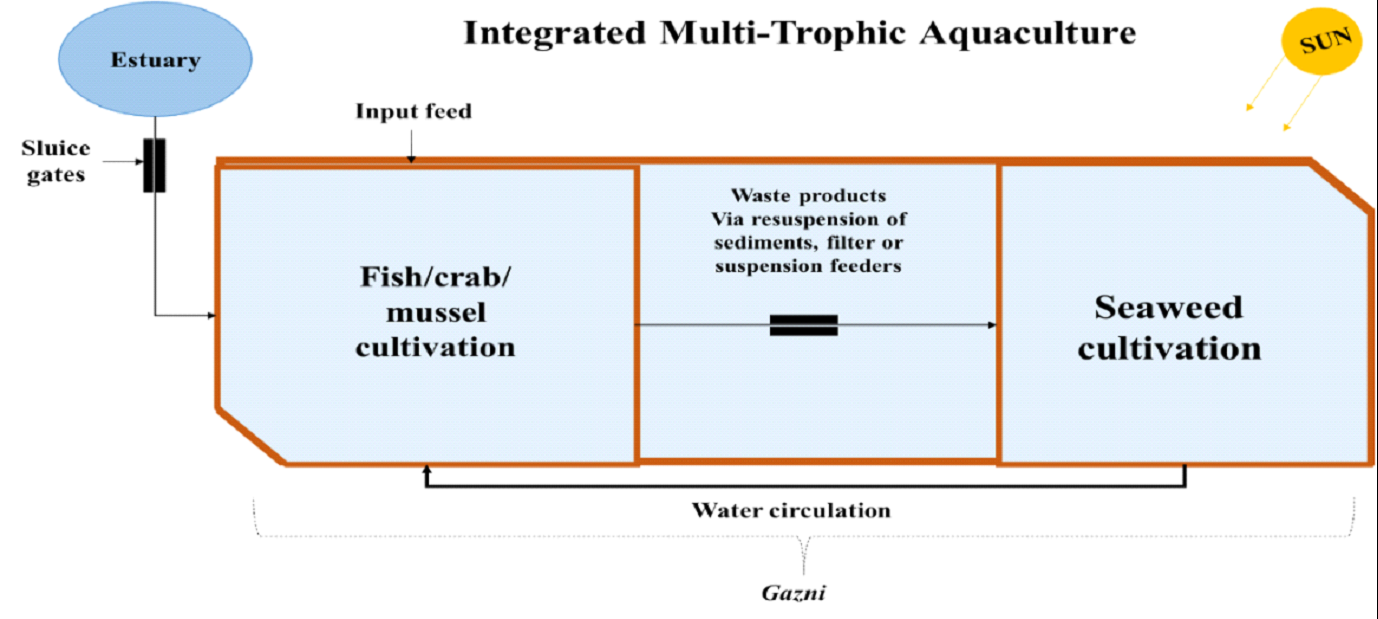

2008). In order to overcome this, Integrated Multi-Trophic

Aquaculture (IMTA) (Fig. 8) concept is introduced, which farming

macroalgae in close proximity to other species at different

trophic level on land. Land-based seaweed cultivation with

adaptation to much wider range of macroalgal genera offers raw

materials for higher-value product development. Intertidal

species like Ulva sp. and Enteromorpha sp.

have high tolerance to temperature and irradiance ranges, which

can be cultivated in IMTA system. Cultivation of seaweeds for

biofuel productions needs to be encouraged to meet the future

fuel demand as seaweeds have high potential as feedstock for

biofuel production as part of the Nation’s strategic energy

security program. This would also empower rural women with job

opportunities. Development of seaweed-based industries at

decentralized levels along coastal areas, where resources are

abundantly available would enhance the job opportunities for the

rural youth. Seaweed cultivation as a notable future enterprise

can open up platform for establishing seed hatcheries, seeding

units and processing units and enhance employment opportunities

in rural coastal area

Fig. 8. Integrated

Multi-Trophic Aquaculture Model

|