|

Introduction

Major commercial energy sources such as oil, coal and natural gas are extracted from fossil fuels. Burning of fossil

fuel results in the escalation of CO2 in the atmosphere- a major cause for global warming, price

volatility, air pollution and environmental degradation (Adenle et al., 2013; Naik et al., 2010). Surging demand in

these sectors has led to increase in oil production from the finite source of fuel reserves. Continuous exploitation

is depleting these reserves at staggering speed and will no longer suffice the world’s energy demand (del Río et

al., 2020; Goli et al., 2016; Hirsch et al., 2005; Raheem et al., 2018) leading to global energy crisis. Hence,

fossil fuels are regarded as unsustainable and questionable from economic, ecology and environmental point of view

(Naik et al., 2010). Therefore the quest for an economical, renewable, sustainable and environmentally benign source

of energy is underway (Hahn-Hägerdal et al., 2006; Tripathi et al., 2016). Biomass energy in the form of cow dung

cake, firewood, agriculture residue and other natural feedstock for cooking and heating have been prevailing from

ages which contributes to 80% of rural energy in developing countries like India (Kumar et al., 2015; Ramachandra,

2010 , 2000, 2004). Biofuels from biomass such as plants, algae or organic waste are emerging as promising

alternative renewable energy sources to liquid fuels ((Jambo et al., 2016). Different technologies have evolved

towards the conversion of biomass into fuels and other value added products that have the advantage of mitigating

global warming by cutting down the carbon dioxide emission, as CO2 is fixed by the biomass via

photosynthesis, making it a carbon neutral emission (del Río et al., 2020) and also ease the dependency on oil

reserve (Bhattacharyya, 2006; Kumar et al., 2015; McKendry, 2002; Naik et al., 2010). Biofuels are of two types

bioethanol and biodiesel; bioethanol are produced from carbohydrate rich algal biomass (e.g. macroalgae) whereas,

biodiesel is produced from lipid rich algal biomass (e.g. microalgae). Dependence on fossil fuels (gasoline) in

transport sector can be reduced by bioethanol, as it is effective in replacing or blending with gasoline.

Development and commercialization of bioethanol is largely achievable due to the availability of feedstock in large

quantum (Jambo et al., 2016). Bioethanol feedstocks are categorised into first, second and third generation based on

the feedstock’s carbon source. Bioethanol from first generation feedstock (1G) involved food crops like corn and

sugarcane, which encountered resistance due to the arable land, freshwater source for its cultivation and

competition with food crops (Naik et al., 2010). The lacunae of 1G bioethanol in supplementing the growing energy

demand led to the exploration of alternate feedstock involving agricultural residues and woody biomass rich in

lignocellulose (second generation (2G) bioethanol feedstock). However, 1G and 2G bioethanol production failed, due

to process technology involving the cost-intensive delignification process and difficulty in scaling up (Zhu and

Pan, 2010). Bioethanol potential from 1G and 2G feedstock marginally complies with various other sustainability

criteria’s such as; conversion of ecologically vulnerable wetlands, extensive usage of fertilizers, soil erosion,

rainforests, peat lands, savannas into energy crop lands, disruption of global food supply contributing to several

magnitude of CO2 (Gasparatos et al., 2013; Maeda et al., 2015). Bioethanol production from third

generation feedstock (3G) involves algal biomass that are grown in fresh water, wastewater (Ramachandra et al.,

2013) and marine waters with zero nutrient input and more importantly, non-interference with the lands required for

food production (Demirbas, 2008; Odum and Heald, 1972). At present, the research focus is currently on bioethanol

production from 3G feedstock due to higher photosynthetic efficiency (6-8%), productivity (~13.1 kg dry

weight/m2 over 7 months), ease of cultivation, low consumption of fertilizers, no alteration with food

supply, and high absorption of CO2 (8-10 tonne CO2 per hectare) (Kraan, 2013),

potential to obtain high value added products (pigments, cosmetics, food additives etc.). Algal biomass has emerged

as one of the ideal feedstock for achieving sustainable biorefinery having immense potential for commercialization

(Jambo et al., 2016).

|

Fig.1. Bioethanol production process from biomass |

Bioethanol production from algal biomass

Production of bioethanol from algal biomass involves three steps; pretreatment, saccharification and fermentation

which are discussed in detail in the subsequent sections. Algae are of two types - micro and macroalgae. Microalgae

are explored for production of biodiesel (Ramachandra et al., 2009; Saranya et al., 2018), whereas macroalgae rich

in carbohydrate are suitable for production of bioethanol (Borines et al., 2013; John et al., 2011; Ramachandra

& Hebbale, 2016; Ramachandra & Hebbale, 2020; Roesijadi et al., 2010; Wei et al., 2013; Yanagisawa et al.,

2013). Macroalgae (commonly known as seaweeds) are multicellular, photosynthetic algae growing in marine environment

and lesser extent in brackish waters. Photosynthetic pigments in seaweeds imparts characteristic range of colors

such as red (Rhodophyta), green (Chlorophyta) and brown (Phaeophyta) algae (Abbott et al., 1992; Smith, 1938; Van

Den Hoek, 1984). Green seaweeds are euryhaline i.e. tolerating a wide range of salinity whereas, red and brown

seaweeds are strictly marine dwelling. Seaweeds have a wide range of distribution from tropics, temperate, polar,

tidal pools, estuaries, deep waters and rocky shores whereas, brown seaweed species belonging to order Laminariales

occur mostly in temperate regions (<24oC) (Abbott et al., 1992). Seaweeds

grow by attaching to a substrate (natural or artificial); for need of stable anchorage large seaweed beds are

restricted to rocky substrate (Abbott et al., 1992; Speight and Henderson, 2013). Macroalgal tissues lack

specialized translocatory systems and structure of the “higher plants” (Abbott et al., 1992). Macroalgal body is

rootless, stemless and leafless entity called thallus, although many have superficially leaf-like blades, stem-like

stipes and often having attaching organs called holdfast or haptera (Lobban et al., 1994; Smith, 1938). Most algae

lack these structures owing to their morphological adaptations and modifications (Abbott et al., 1992). Seaweeds

reproduce either asexually or sexually (Lobban et al., 1994). Asexual reproduction is a common mode of reproduction

in seaweeds.

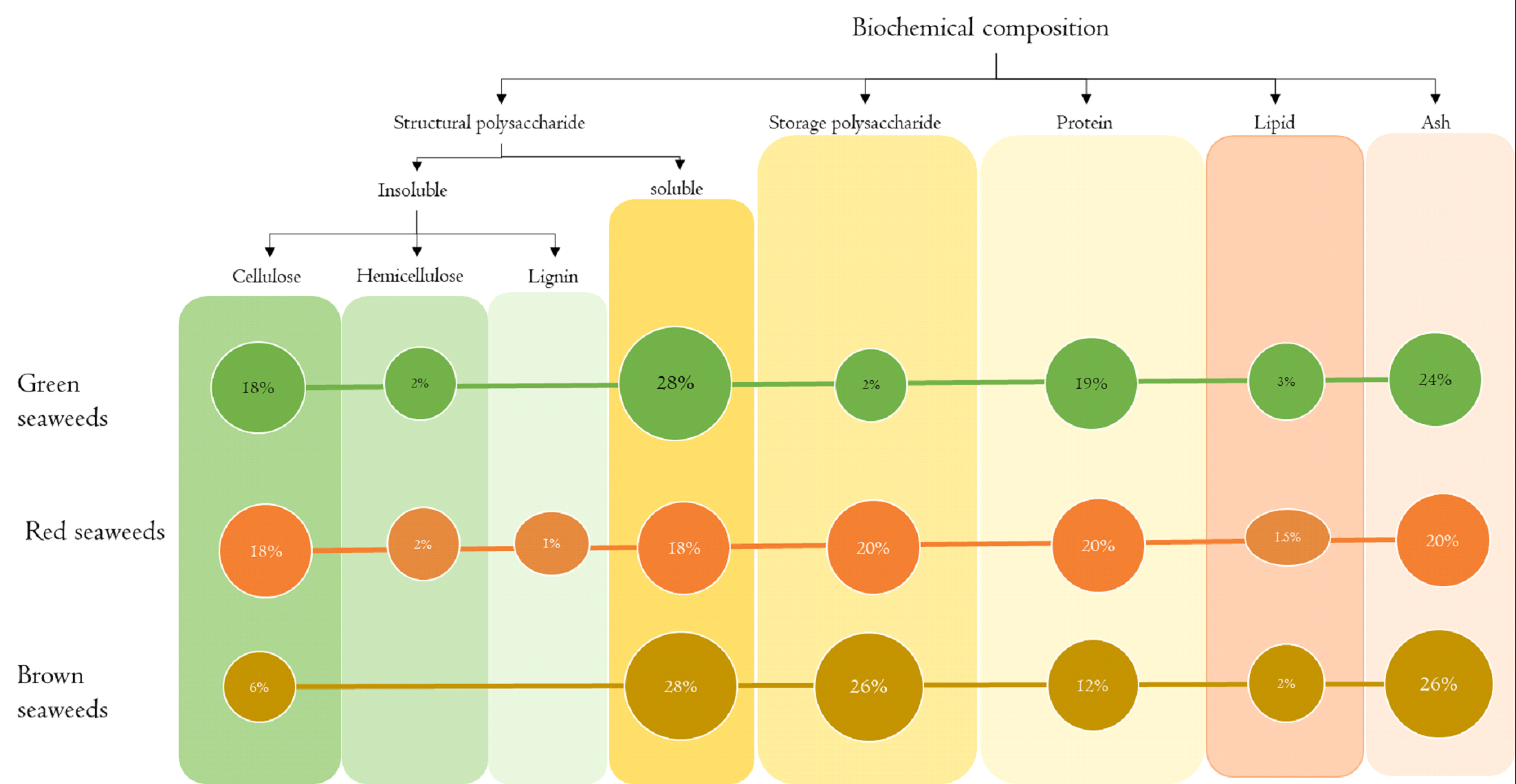

Fig.2. Macroalgal biochemical composition profile

Generally, the range of biochemical composition of seaweeds are; carbohydrate: 25-77% dry weight, proteins: 5-43% dry

weight, lipid: 1-5% and ash content: 9-50% dry weight followed by higher water content of 70-90% fresh weight (Jung

et al., 2013; Praveen et al., 2019). Seaweeds consist of varied profiles of structural and storage carbohydrate

(Daroch et al., 2013; Kostas et al., 2016) based on the respective intercellular spaces and cell wall (Pereira and

Neto, 2014) (Fig 2).

Seaweed polysaccharides show a range of structures and fulfil a variety of functions similar to neutral sugars and

sugar acids of terrestrial plants. Certain seaweeds also contain acidic half ester sulphated groups attached to

hydroxyl groups of sugars. Hexose sugars such as glucose, galactose and mannose found in these polysaccharides have

identical chemical composition. Carbohydrate reserves of red algae are usually stored in the form of small grains

that lie in the cytoplasm outside the algal plastids, the chromatophores. The insoluble carbohydrate reserve of red

algae has been called floridean starch (intermediate between true starch and dextrin) (Yu et al., 2002).

Polysaccharides such as starch and cellulose in green algae are similar to that of terrestrial plants. Macroalgal

biomass lacks lignin in their composition (Jung et al., 2013) except in few red seaweed species. Apart from higher

content of carbohydrates in seaweeds, protein and ash contents are also relatively higher; however, lipid fraction

is considerably low.

An effective bio-refinery process is achieved by characterization of the feedstock employed such as large variety of

carbohydrate (mono-, di-, polysaccharides) serves as raw materials for bioethanol production. Quantification of

carbohydrate content (Table 1) in the biomass is an essential step in biorefinery process as it is directly

proportional to ethanol yields in biochemical conversion process and facilitates overall process efficiency

calculations as well as mass balance (Aden et al., 2002; Kostas et al., 2016). Seaweeds accumulate large

concentrations of carbohydrates (polysaccharides) made up of various monosaccharides such as xylose, glucose,

galactose and fructose. These sugars are converted to bioethanol through fermentation via appropriate

microorganisms.

Availability of macroalgal feedstock

Macroalgae occur along the nutrient rich coastal zones by attaching on hard substratum. Global seaweed distribution

is highest between 60oN and 60oS latitude with 900-1100 species, least species are recorded

>60o in both hemispheres, in these regions, mostly cold water desiring macroalgae are recorded such as

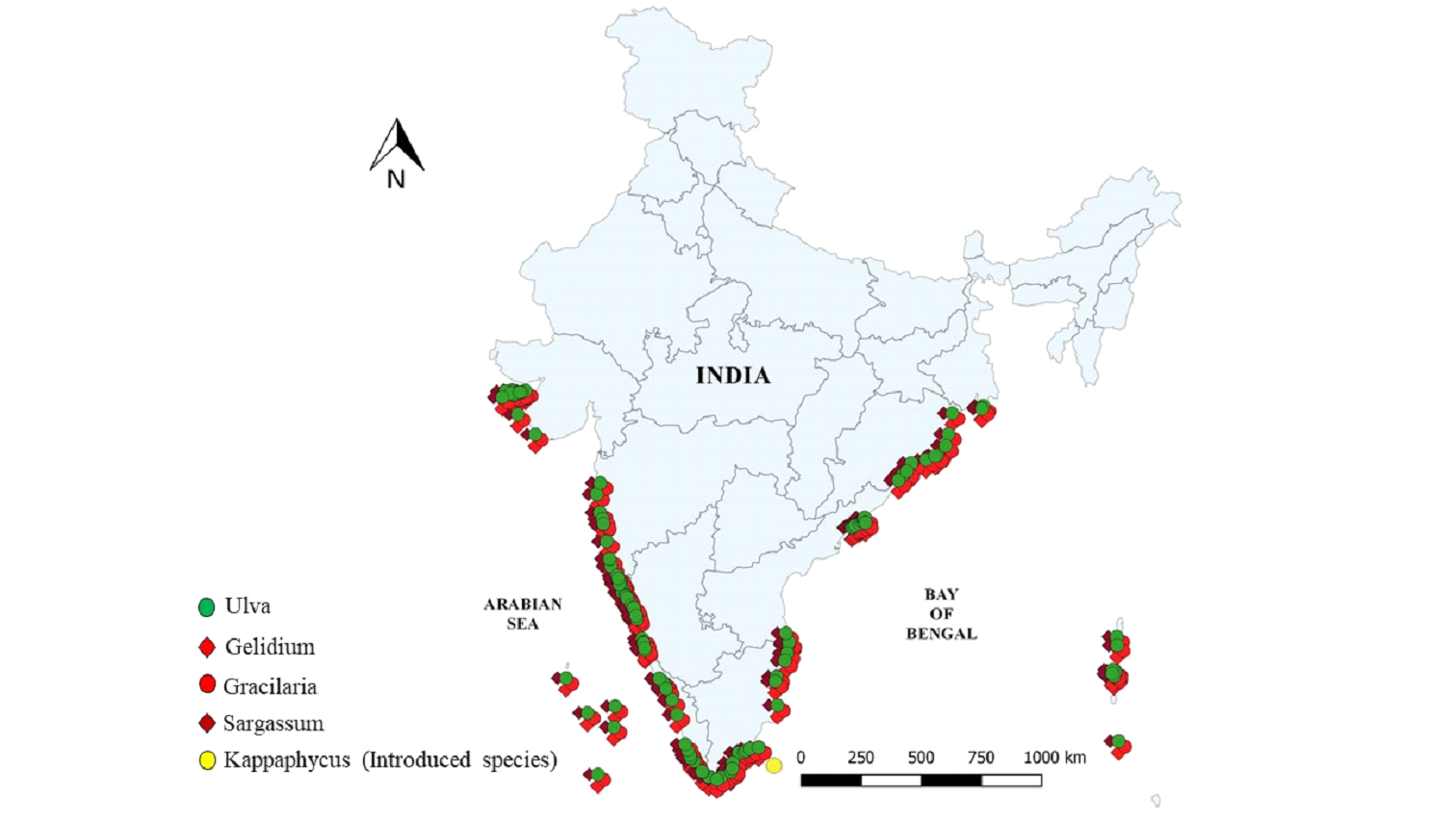

Laminaria, Undaria etc. (Hurd et al., 2014). The most prominent macroalgal genera explored for

bioethanol potential is indicated in Fig 3. along the coastal regions of India.

Table 1. Biochemical composition and monosaccharide profile of potential

macroalgal genera for bioethanol production |

Biochemical composition (%)/ 100 g dry biomass |

Ulva sp. |

Gracilaria sp. |

Gelidium sp. |

Sargassum sp. |

Kappaphycus sp. |

Laminaria sp. |

Ash |

18-49.6 |

22.9-26 |

2.5-4.8 |

40.0-46.0 |

18.0-19.7 |

8.7-41.2 |

Lipid |

1-3.5 |

0.7-6 |

0.7-7.4 |

0.75-2.5 |

0.2-0.75 |

0.6-3.4 |

Protein |

10.7-25.9 |

4.3-16 |

10.2-18.7 |

10.25-15.42 |

2.3-5.74 |

1.1-19.8 |

Carbohydrate |

53-69.9 |

30.4-76.67 |

53.2-75.8 |

23.5-41.81 |

51.6-59.58 |

33.9-76 |

Monosaccharides composition/ 100g carbohydrate |

|

3,6-Anhydrogalactose |

|

|

28.9-43.5 |

|

|

|

Arabinose |

0.0-0.8 |

|

|

|

|

|

Fucose |

0.2-0.4 |

|

33.6-57.0 |

0.2-7.4 |

|

4.2-8.5 |

Galactose |

7.2-8.5 |

30.6-42.8 |

21.8-40.6 |

0.0-4.0 |

20.3-22.39 |

|

Glucose |

0.2-25.4 |

20.5-24 |

|

22.5-65.6 |

0.4-0.78 |

24.5-62.2 |

Mannitol |

|

|

0.0-0.8 |

0.2-5.04 |

|

11.2-37.9 |

Mannose |

0.0-4.2 |

0.0-0.07 |

0.0-0.4 |

0.0-4.0 |

|

|

Rhamnose |

3.3-12.7 |

|

|

|

|

|

Ribose |

0.1-2.7 |

|

|

|

|

|

Uronic acids |

25.9-28.8 |

|

|

|

|

20.8-41.6 |

Xylose |

5.6-14.4 |

0.0-0.3 |

0.0-1.3 |

0.5-19.4 |

|

6.0-12.0 |

Bioethanol (L/100kg dw) |

5.58-11.7 |

2.6-4.7 |

1.62 |

4.4 |

1.7-2.4 |

5.4-26.2 |

(Abd-Rahim et al., 2014; Borines et al., 2013; Chennubhotla et al., 1990; Masarin et al.,

2016; Parthiban et al., 2013; Sung-Soo Jang, 2012; Wu et al., 2014; Yeon et al., 2011) |

Fig. 3. Distribution of macroalgal species along the coastal regions across the India,

explored for bioethanol production potential ( Ramachandra & Hebbale, 2020)

Pretreatment

Bioethanol production from macroalgae requires extraction of fermentable sugars, several studies have reported (Table

2) of different pre-treatment techniques including chemical, physical or biological or combination of these

techniques through which higher sugar concentration can be obtained (Feng et al., 2011; Kim et al., 2014; Meinita,

Kang, et al., 2012; Park et al., 2012; Yoon et al., 2010). Pretreatment of biomass is carried out to reduce the size

and alter or remove structural and compositional impediments prior to subsequent enzyme hydrolysis. Pre-treatment

needs to be cost effective and release higher quantum of sugar with the minimal inhibitor formation.

Table 2. Assessment of selected pre-treatment processes |

|

Pre-treatment process |

Yield of fermentable sugars |

Physical or physico-chemical

Pre-treatments |

Mechanical |

Low |

Steam explosion |

High |

Ammonia fibre explosion (AFEX) |

Moderate |

Carbonic acid |

Very high |

Chemical pre-treatments |

Dilute acid |

Very high |

Concentrated acid |

Very high |

Alkaline extraction |

Very high |

Wet oxidation |

High |

Organosolvent |

Very high |

Biological pretreatments |

Commercial Enzymes or bacterial/fungal enzymes |

Very high |

Source: (Hendriks and Zeeman, 2009; Wooley et al., 1999) |

Most commonly used chemical pretreatment method for obtaining higher fermentable sugars from macroalgal biomass is

dilute acid pretreatment method, that employs mineral acids such as H2SO4 and HCl at milder

concentrations of 0.3-0.9N (Meinita et al., 2012a; Park et al., 2012). During dilute acid pretreatment process,

reaction parameters such as reaction time, acid concentration, and substrate concentration is involved for efficient

sugar release from algal feedstock (Table 3). Pre-treatment with dilute- H2SO4 at optimal

concentration and temperature is reported effective for cell-wall depolymerization. The advantage of dilute acid

pretreatment method is lower energy consumption as compared to other pre-treatments. However, disadvantage of dilute

acid pretreatment is formation of fermentation inhibitors such as 5-Hydroxymethyl furfural (HMF) and levulinic acid

(LA) with the degradation of hexose sugars and furfurals from pentose sugar degradation. Hence, enzyme hydrolysis

has been opted as sustainable option for hydrolysis as it does not involve formation of any

inhibitors because enzymes do not cause degradation of monosaccharides (Yanagisawa et al., 2013).

Table 3. Reducing sugar yield reported from macroalgal feedstock at different dilute

H2SO4 concentration |

Macroalgal species |

Dilute H2SO4 concentration |

Reducing sugar yield |

Reference |

Gracillaria verrucosa |

1.5% |

430 mg/g |

(Kumar et al., 2013) |

373 mM |

7 g/ l |

(Nguyen et al., 2017) |

0.1 N |

7.47 g/L |

(Kim et al., 2015) |

Kappaphycus alvarezii

|

0.9 N |

300 mg/g |

(Khambhaty et al., 2012) |

1% v/v |

81.62 g/L |

(Hargreaves et al., 2013) |

0.2 M |

30.5 g/L |

(Meinita et al., 2012) |

Laminaria japonica |

0.06% |

29.09% |

(Lee et al., 2013) |

Gelidium amansii |

3% |

33.7% |

(Park et al., 2012) |

Enzyme saccharification

Biological pretreatment method employs substrate specific enzymes (Fig 4). Major portion of macroalgal cell wall is

composed of cellulose, which is made up of glucose subunits, in order to break the cellulose structure cellulase

enzyme is commonly used. Similarly, agarases is used for agar, carageenase for carrageenan, alginase for alginate

and laminarases for laminarin. Pretreatment is a prerequisite prior to enzyme saccharification, as it opens up the

cellulose fibrils and maximizes the enzymatic conversion of cellulose (Harun, 2011; Jeong et al., 2013; Kang et al.,

2013; Kim et al., 2014). Commercial enzymes as well as enzymes extracted from bacteria or fungi are reported for

enzyme saccharification of macroalgal biomass (Table 4).

Enzyme saccharification of cellulose to glucose is considered an environmentally friendly pretreatment process.

However, this research is at a nascent stage, orientated toward isolating efficient enzyme systems (Swain et al., 2017)

from microorganisms that produce cellulolytic enzymes in their metabolic processes (Bhat and Bhat, 1997; Niehaus

et al., 1999; Zhang and Kim, 2010). Higher concentrations of extracellular cellulase enzymes have been reported from

bacteria and fungi that are feasible for large-scale production. Terrestrial sources for cellulase enzyme have been extensively explored and investigated; however, studies related to cellulase extraction from marine source is still an unexplored platform. A large reservoir of microbes thrives in the marine ecosystem at extreme conditions of salt,

temperature, and high pressure (Trivedi et al., 2016), which imparts well-developed cellular machinery and

stable enzymes, offering novel biocatalysts with unusual properties which can be explored for bioethanol production

(Gao et al., 2010; Zhang and Kim, 2010).

15.2.4 Fermentation

Sugars obtained from dilute acid hydrolysis, enzyme saccharification, or a combination of both are subjected to fermentation, where microorganisms consume the sugar as their sole source of carbon and metabolize it for their growth and

reproduction and yield ethanol as a by-product. Fermentation is dependent on the simple sugars; seaweeds consist of

both C6 and C5 sugars, but not all the microorganisms can metabolize both the sugars simultaneously. Hence the choice

of the organism for fermentation plays a pivotal role. The most widely used microorganism for ethanol fermentation is

Saccharomyces cerevisiae, which metabolizes hexose (C6) sugars. Fermentation of glucose alone will not produce high

yields of ethanol. Pichia stipitis and Pichia angophorae can metabolize pentose (C5) sugars. Other than yeast microorganisms, bacteria such as Pacchysolan tannophilus and Escherichia coli have also been studied for ethanol production

from hexose and pentose sugars. Macroalgae are also composed of sugar alcohols that are not metabolized by yeast

microorganisms; Zymobacter palmae isolated from palm was observed to convert mannitol present in brown algae into

ethanol (Horn et al., 2000a,b).

Glucose is metabolized in a series of enzyme-catalyzed reaction processes called glycolysis to yield two molecules

of three-carbon compound pyruvate. Under hypoxic or anaerobic conditions, pyruvate is decarboxylated, and acetaldehyde is reduced to ethanol through alcohol dehydrogenase (Nelson and Michael, 2008). Xylose is converted to xylulose

and phosphorylated to xylulose-5-phosphate and further metabolized to glyceraldehyde-3-phosphate and fructose-6-

phosphate, which then enters the glycolysis pathway for subsequent pyruvate and ethanol production (McMillan, 1993),

as illustrated in Fig. 15.5.

S. cerevisiae is the predominant microorganism utilized in ethanol fermentation in industrial bioethanol production

processes. Ethanol is produced via homoethanol pathways, by EmbdenMeyerhofParnas (EMP) glycolytic pathway,

|

Fig 4. Schematic representation of enzyme action on substrate |

Table 4. Reducing sugar yield reported from macroalgal feedstock using enzymes |

Macroalgal Feedstock |

Enzymes hydrolysis |

Sugar yield |

Reference |

E. intestinalis |

Viscozyme L and Cellic CTec2 |

20.1 g/L |

(Kim et al., 2014) |

|

Celluclast 1.5 L and Viscozyme L |

40 g/L |

(Cho et al., 2013) |

|

|

U. fasciata |

Cellulase 22119 |

215 mg/g |

(Trivedi et al., 2013) |

|

Viscozyme L |

206 mg/g |

|

Cellulase isolated from Cladosporium sphaerospermum |

112 mg/g |

( Trivedi et al., 2015) |

|

U. pertusa |

Meicelase-Simple saccharification |

43 g/L |

(Yanagisawa et al., 2011) |

|

|

Meicelase |

78.8 g/L |

|

Meicelase |

59.1 g/L |

|

Cellulase & Amyloglucosidase |

26 |

(Choi et al., 2012) |

|

|

G. elegans |

Meicelase |

70.9 g/L glucose |

(Yanagisawa et al., 2011) |

|

53.2 g/L galactose |

|

G. amnasii |

Cellulase 0.98 FPU/g β-glucosidase 10.4 U/g |

43.7% glucose |

( Kim et al., 2015) |

|

12% galactose |

|

K. alvarezii |

Celluloclast 1.5 L & Novozyme |

11 g/L |

(Tan and Lee, 2014) |

|

Multifect |

81 g/L |

(Hargreaves et al., 2013) |

|

G. amansii |

Enzyme Viscozyme L |

2.4 g/L |

(Ra et al., 2013) |

|

G. amansii |

Celluclast (0.168 EGU/ml) |

10.5 g/L |

|

G. verrucosa |

10% enzyme extract |

7.47 g/L |

(Kim et al., 2015) |

|

A. crassifolia |

Meicelase |

66.3 g/L |

(Yanagisawa et al., 2011) |

|

|

S. japonica |

Enzyme Cellulase- 45 FPU/g Cellobiase-55 CBU/g |

268.5 mg/g |

(Ge et al., 2011) |

|

U. pinnatifida |

Celluclast 1.5 (4ml/100g of cellulose) Novozyme 188 |

65 mg/g |

( Lee et al., 2011) |

|

Sargassum. sp. |

10 FPU cellulase /g ,250CBU cellobiase/g |

120 mg/g reducing sugar |

(Borines et al., 2013) |

|

S. japonica |

Novozyme (Termamyl 120L) |

20.6±1.9 g/L |

(Jang et al., 2012) |

|

Saccharomyces cerevisiae, is the predominant microorganism utilized in ethanol fermentation in industrial

bioethanol production processes. Ethanol is produced via homoethanol pathways, by Embden-Meyerhof-Parnas (EMP). The

EMP (glycolytic) pathway, summarized below (Walker & Walker, 2011):

Glucose + 2ADP + 2Pi + 2NAD+->Pyruvate + 2ATP + 2NADPH + 2H+

Saccharomyces cerevisiae reoxidizes the reduced co-enzyme NADH to NAD+ in terminal fermentative

step reactions emanating from pyruvate:

2Pyruvate + 2NADH + 2H+->NAD+ + 2Ethanol + 2CO2

The intermediate compound, acetaldehyde, acts as the electron acceptor

NAD+ is re-generated by alcohol dehydrogenase which requires zinc as an essential co-factor for its activity.

Fermentation thus maintains the redox balance by regenerating NAD and keeps glycolysis proceeding. In doing so,

yeast gets energy for its own maintenance by generating 2ATP. The theoretical (stoichiometric) conversion to ethanol

from glucose is as follows:

Fig.5. Glucose and Xylose metabolism and conversion to

ethanol

For each kilogram of glucose fermented, around 470 g of ethanol can be produced (i.e., <50%) representing a yield

of 92% of theoretical maximum. In industrial fermentation practice, however, the best yields are only around 90% of

this theoretical conversion due to the diversion of fermentable carbon to new yeast biomass and minor fermentation

metabolites (organic acids, esters, aldehydes, fuel oils etc). Bioethanol production from macroalgal biomass is

carried out either by Separate Hydrolysis and Fermentation (SHF) or Simultaneous Saccharification and Fermentation

(SSF) process. In SHF process, dilute acid hydrolysis/enzyme saccharification and fermentation are carried out

separately. This process involves higher operating cost, energy consumption and more reaction time. Not all the

sugars in the medium is utilized at the end of this process. In SSF process, enzymatic saccharification and

fermentation is achieved in the same reactor. This process is favourable as it requires slower process time, lower

energy consumption and yield higher ethanol. However, the process time required for both enzyme and yeast

microorganisms are different which results in slower release and consumption of sugar. Lower concentrations of

inhibitors are formed in SSF process.

Current Status

Kappaphycus, Gelidium, Gracilaria, Sargassum, Laminaria and Ulva, are largely cultivated

macroalgal genera for hydrocolloid extraction and human food usage by China, Philippines and Indonesia. However in

recent years these genera are regarded as potential feedstock for biofuel production in addition to the value added

products for phycocolloids extraction, human food, cosmetics, fertilizer and other chemicals (Harun, 2011; Jang,

Cho, Jeong, & Kim, 2012, Dhargalkar & Pereira, 2005; McHugh, 2003; Yanagisawa et al., 2013). Species from

these genera have been chosen considering the availability and assessment of resources around the globe, ease of

cultivation and harvesting. Shorter life cycles of seaweed are taken into advantage for largescale cultivation,

which is cost-effective and involves environmentally friendly methods, zero input of fertilizers, and no changes in

land use as they are exclusively grown in marine waters. Laminaria is most cultivated seaweed with average

production of 5.14 million tonnes (Alaswad et al., 2015).

Table 5. Current status of seaweed utilization |

Species |

Food |

Feed |

Industrial |

Medicine |

Fertilizer |

Biofuel feedstock |

Ulva fasciata* |

+ |

+ |

- |

+ |

- |

+ |

Enteromorpha compressa* |

+ |

+ |

- |

+ |

- |

- |

Enteromorpha intestinalis* |

+ |

+ |

- |

+ |

+ |

+ |

Monostroma oxyspermum |

+ |

+ |

- |

- |

- |

- |

Cladophora fascicularis* |

+ |

+ |

- |

- |

- |

- |

Chaetomorpha media* |

+ |

+ |

- |

- |

+ |

- |

Codium fragile |

+ |

+ |

- |

+ |

- |

- |

Caulerpa sertularioides |

+ |

+ |

- |

- |

- |

- |

Dictyota dichotoma* |

+ |

+ |

+ |

- |

- |

+ |

Spatoglossum asperum* |

- |

- |

+ |

- |

+ |

+ |

Hydroclathrus clathratus |

- |

- |

+ |

- |

+ |

- |

Stoechospermum marginatum |

- |

- |

+ |

- |

+ |

- |

Colpomenia sinuosa |

- |

- |

+ |

- |

+ |

- |

Dictyopteris australis |

- |

- |

+ |

- |

+ |

- |

Padina tetrastromatica |

- |

- |

+ |

- |

+ |

+ |

Sargassum cinereum* |

- |

- |

+ |

+ |

+ |

+ |

Sargassum ilicifolium* |

- |

+ |

+ |

+ |

+ |

+ |

Laminaria digita |

- |

- |

+ |

+ |

+ |

+ |

Macrocystis pyrifera |

- |

- |

+ |

+ |

- |

+ |

Porphyra vietnamensis* |

+ |

+ |

- |

- |

- |

+ |

Amphiroa fragillissima* |

+ |

- |

- |

- |

- |

- |

Jania adhaerens* |

- |

- |

- |

+ |

- |

- |

Gracillaria corticata* |

+ |

+ |

+ |

- |

- |

+ |

Hypnea musciformis* |

+ |

+ |

+ |

- |

- |

+ |

Centroceros clavulatum |

+ |

- |

+ |

- |

+ |

- |

Laurencia papillosa* |

+ |

+ |

+ |

- |

- |

- |

Chondrus crispus* |

+ |

- |

+ |

- |

- |

+ |

Eucheuma uncinatum |

+ |

+ |

+ |

- |

- |

+ |

Gelidiella acerosa* |

- |

- |

+ |

- |

- |

+ |

* Seaweeds distributed along Indian Coast. |

|

Bioethanol of 40 g/L is reported from green seaweed by the glucose subunits alone, whereas other sulphated

polysaccharides such as, Ulvan is yet to be explored. In brown seaweeds, mannitol is fermented to produce 40 g/L of

bioethanol whereas, techniques for conversion of alginate sugar to ethanol is still underway. Whereas, in red

seaweeds 3,6 anhydrogalactose (composed of glucose and galactose) poses a hindrance for conversion to ethanol

(Yanagisawa et al., 2013). Higher concentration of bioethanol is obtained by conversion of all the sugars present in

the seaweed which can be achieved by developing methods appropriate to each seaweed species.

Challenges in bioethanol production

Following are the challenges to be addressed for successful bioethanol production from macroalgal biomass

- Major cost reductions need to be achieved by suitable biocatalyst and optimal processes.

- Microorganisms possessing enzymes, which have ability to convert polysaccharides to fermentable sugars needs to

be screened or constructed.

- Commercial enzymes such as amylases, cellulases and proteases are available, but they are more efficient in

depolymerizing polysaccharides from terrestrial sources. To produce, these enzymes for commercial use, microbial

bioreactors are utilized by exploiting the microalgal strains to accumulate carbohydrate and directly utilize

their enzymatic or anaerobic digestion systems to produce ethanol, resulting in a cost-effective bioethanol

production process. In order to proceed with this procedure, screening of high carbohydrate accumulating

seaweeds from natural water bodies based on their growth cycle is to be known.

- Large-scale production to be economical, needs to utilize all sugars present in macroalgal biomass to achieve

100% efficiency.

- Mannitol is a non-fermentable sugar alcohol produced from brown algae, most of the anaerobic bacteria are unable

to carry out fermentation of mannitol as there is requirement of oxygen for regeneration of NAD+ for conversion

of NADH to NADPH which is obtained from mannitol dehydrogenase during oxidation of mannitol to fructose and

NADH. A facultative anaerobic bacterium, Zymobacter palmae ferments sugar alcohols, including mannitol

from Laminaria hyperborea extracts. Pichia angophorae is also seen to consume both mannitol

and laminarin and yield ethanol. Similar investigation to be carried out for ulvan, alginate, 3,6

anhydrogalactose conversions to bioethanol.

- Bioethanol is an intermediate product obtained during digestion of organic material, and is produced by specific

microbial strains only which makes it an obvious practical constraint of keeping the microbial culture from

getting contaminated by other microbes (Horn et al., 2000b, 2000a; Nguyen et al., 2017). Hence a controlled

condition needs to be maintained.

- Setting up of decentralised biorefinery systems in coastal areas with supporting infrastructure (e.g. roads,

utilities).

- Economically feasible algal bioethanol can be turned into a reality only through breakthrough technological

innovations. Getting algae to produce bioethanol—in very large volumes, at a very low cost—is the grand

challenge that young biotech firms have to shoulder.

|