|

Results and Discussion

Results and Discussion

Isolation and screening of ethanologenic wild yeast

strains

Fruits serve as microhabitats for a variety of yeast species.

Therefore bioprospecting of yeasts from fruits is advantageous

[32]. Yeasts isolated from 100 samples (98 fruit sources and two

fermented products) were screened in the current study. Colonies

were observed in 89 samples, and colony morphology was recorded

by incubating the strains at 35oC for 24h. Colony

morphology of isolated yeast presented elongated (24.72%), oval

(14.61%), rounded (60.67%) shape, Large (6.7%), medium (23.6%),

or small (69.66%) size, cream (39.33%) or white (57.3%) or

yellow (3.37%), irregular (48.31%) or regular (51.69%) borders,

bright (49.44%) or opaque (22.47%) or smooth (28.09%) texture.

Yeast exhibit variation in the ability to ferment and assimilate

various sugars, which also aids in the identification of yeast

than morphological and physiological characteristics. Certain

genera of yeast such as Saccharomyces, Torulaspora, and

Zygosaccharomyces ferment glucose readily, whereas;

Lipomyces and Sterigmatomyces are strictly non-fermentative

genera of the yeast. In this study, it was seen that about

74.16% and 71.91% of yeast strains readily fermented sucrose and

glucose, respectively. Glucose as a carbon source allows faster

growth within 24h, which is due to the presence of 20 different

glucose transporters in their plasma membrane [32]. Sucrose, a

disaccharide, is assimilated extracellularly by secreting enzyme

invertase. Lactose was fermented by 57.3% yeast strains,

galactose by 55.06% yeast strains, and lowest being maltose by

41.57% yeast. Production of biofuels from second and

third-generation biomass encourages isolation of yeast strains

capable of fermenting xylose. About 69.66% of yeast strains

fermented xylose in the current study. In a similar study[32],

45 yeast strains were isolated from fruits and chicken litter

and observed that yeast strains readily fermented glucose (22%),

sucrose (12.5%), lactose (2.1%), xylose (40%), galactose (8.3%)

and maltose (2.1%). Yeast strains were tested in glucose and

xylose medium as these sugars are major constituents across the

taxonomical groups of green macroalgae. Strains with the highest

biomass in glucose media (>0.5 OD600) and xylose

media (>0.1 OD600) were considered for further

investigations (Supplementary, S1). The screening was done using

the phenotypic microarray method by eliminating strains with

lower redox signal intensity (RSI) in glucose medium [37]. About

40.45% of yeast strains exhibited good growth in glucose media

with the biomass >0.5 OD, and 47.19% of yeast strains

obtained biomass > 0.1 OD in xylose medium. Yeast strain with

full gas production in Durham’s fermentation tube were selected.

About 19 yeast strains (CY, TY, CHY, MY, MFY, GVY, TNY, PLY

FBY2, BAY, FBJY, RJY, GWY, CKY, PWY, WTY, YKY, POY, CUIY) were

screened down for further characterization and fermentation

capabilities. A growth curve study was carried out for the

strains, incubated at 35oC for 24h with samples drawn

at every 1h interval and biomass growth observed at 600nm.

Strains exhibiting a more prolonged exponential phase

(Supplementary, S1) were selected, as it is a proxy for higher

ethanol production as most of the primary metabolites are formed

during this phase [38, 39].

Screening of multi-stress tolerant ethanologenic yeast

strain

Ethanol endurance is an important property that decides the

fermentation efficiency of the yeast strain. Ethanol tolerance

of yeast has been determined as the accumulation of ethanol

during the fermentation process, and ethanol is toxic to yeast

organisms as it inhibits the activity of crucial glycolytic

enzymes involved in ethanol production and hinders amino acid

and glucose transport leading to the loss of cell viability and

inhibition of cell growth [34, 35]. Isolated yeast growth was

recorded in a spectrophotometer (600nm) in terms of turbidity at

different ethanol concentrations. CHY had the highest ethanol

tolerance, up to 10%, followed by CY, TY, and MY, after which

the growth decreased (Supplementary, S2). In a similar study,

yeast strains CHY1011 and CHFY0901 belonging to Saccharomyces genera

exhibited ethanol tolerance up to 5% [42], comparable tolerance

level was recorded for baker’s yeast (positive control) in the

current study whereas, an isolated yeast (Y-1) from wine (Jiuqu)

had ethanol tolerance up to 14% [40]. S.cerevisiae

isolated from Nuruk [43], cashew [44], and soil [45] exhibited

tolerance in a medium containing 15% alcohol.

Yeast growth at different temperatures were monitored.

Thermo-tolerance of yeast is evident up to 37oC, and

growth is inhibited at higher temperatures. PLY strain exhibited

consistent high growth up to 40oC, whereas TY strain

exhibited higher thermotolerance up to 45oC. In a

similar study earlier [46], Pichia kudriavzevii DMKU

3-ET15 isolated from fermented pork sausage displayed

thermo-tolerance up to 45 oC, which is comparable to

TY strain (Pichia kudriavzevii) in the current study

(Supplementary, S3). Candida tropicalis, Pichia

kudriavzevii, Candida orthopsilosis, Candida

glabrata and Kodamea ohmeri were reported as

thermotolerant, and high ethanol-producing yeasts strains [47].

Pichia caribbica isolated from ripe banana was

subjected to different temperatures, displayed good growth at

temperatures 28, 30, 40 oC, which declined at 45oC

[48], contrary to which CY strain (identified as P.carribbica)

exhibited good growth at 35, 40 and 45 oC, which

declined after 45 oC.

Bioethanol process from seaweeds encounters a high concentration

of NaCl due to its habitat [49]. Therefore, isolated yeast

strains were subjected to different salt concentrations, which

show a decline of cell growth with an increase in salt

concentration, similar to S.cerevisiae KCTC 1126. But,

S.cerevisiae KCTC 1126 adapted to NaCl and yielded an

ethanol concentration of 0.48 [50]. Issatchenkia

orientalis MF-121 produced 2.9% (w/v) ethanol in a

medium containing Na2SO4 (50g/L), while

tolerant to multi-stress factors such as temperature, ethanol,

and salt [51]. Halotolerance up to 14% NaCl concentration was

exhibited by WTY strain, however, the strain achieved a lower

ethanol conversion efficiency of glucose and xylose fermentation

(Supplementary, S4).

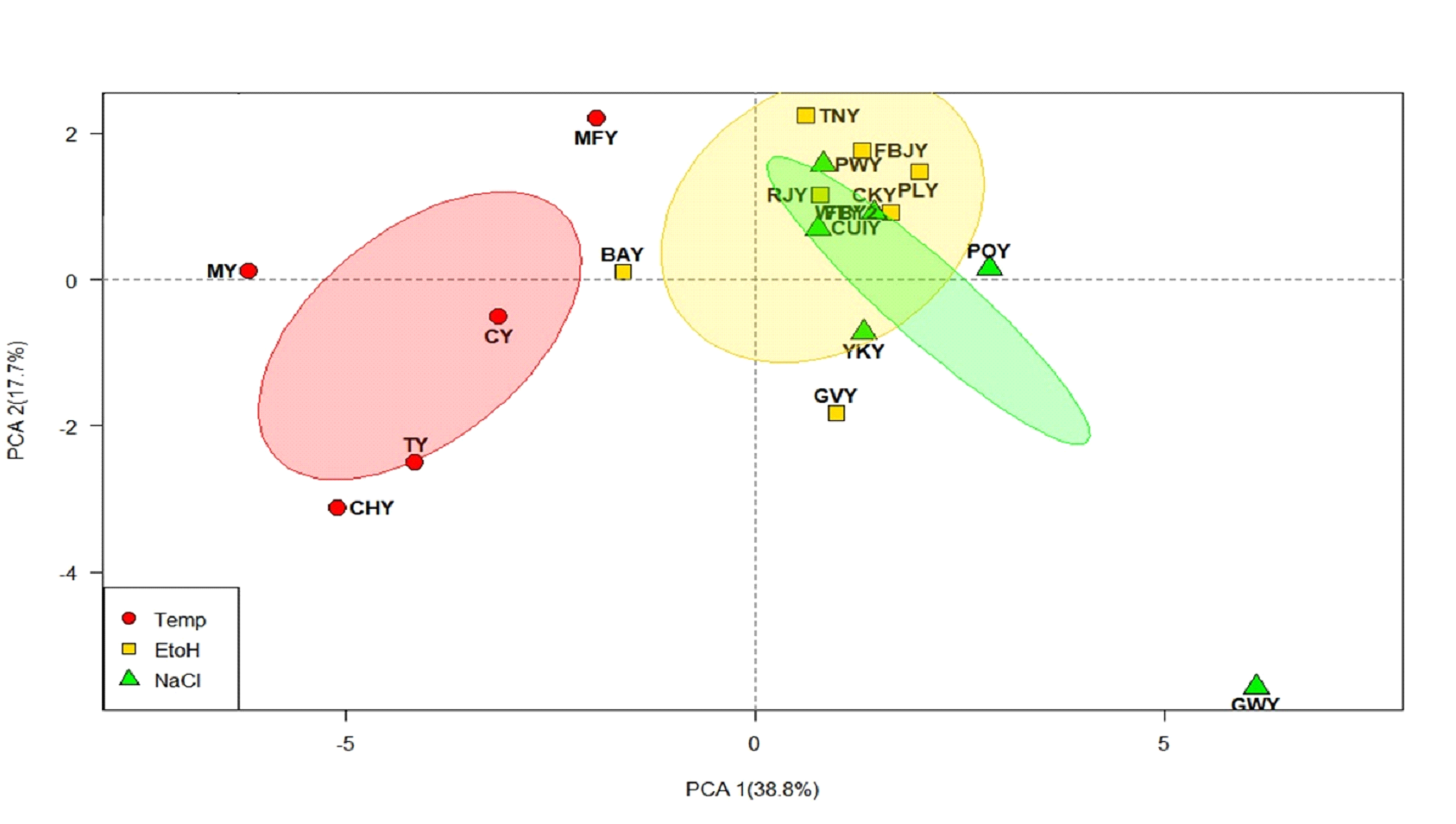

Multivariate analyses through Principal Component Analysis (PCA),

given in Fig. 1a, illustrate strains clustering into three

groups with the clustering of temperature tolerant strains and

overlapping of ethanol and salt-tolerant strains. Principal

components are accounting for 56.5% of the total variance, with

PC1 contributing 38.8% and PC2 contributing 17.7%. Salt tolerant

strains POY, YKY, CUIY, and PWY were located at the positive

side along PC1; on the other hand, thermotolerant species CY, TY

MY, MFY and CHY were closely loaded at the negative side along

PC1. Ethanol-tolerant strains were loaded at the positive side

of PC2. Ethanol production by yeast strains using

a synthetic medium

Fermentation of glucose is an established technology; however,

fermentation of xylose has been posing challenges. During the

fermentation process, 70% of the sugar is converted to ethanol,

whereas 20% assimilated by the yeast cells yield glycerol,

organic acids, etc. [52, 53]. Production of glycerol at a higher

concentration inside the yeast cell is stimulated by factors

such as higher pH, a lower flux of pyruvate (due to the

utilization of glycolytic intermediates), increase in osmotic

pressure, etc. with the formation of by-products (higher

alcohols and organic acids at lower level), affecting the

ethanol yield as the growth of yeast cells invariably directs

the glycolytic intermediates to corresponding pathways.

Ethanologenic yeast strains are evaluated based on the ability

of strains to utilize all sugars (glucose, xylose, galactose,

mannose, rhamnose, and arabinose) and convert to ethanol with

minimal by-product formation [54]. Conventionally, ethanol yield

at an industrial scale is calculated based on the total

sugar-fed into the fermentation system, and 90-93% ethanol

bioconversion is considered for an efficient ethanologenic

strain.

Fig. 1a. PCA score plot of yeast

strains tolerant to stress factors; temperature,

ethanol and salt concentration

Fig. 1b. Multivariate cluster

analysis of yeast strains

Glucose is abundantly found sugar in the feedstock and is readily

fermented by yeast microorganisms. Yeast prefers glucose over

xylose, and xylose uptake is regulated by glucose concentration

[55, 56]. Glucose is metabolized in a series of enzyme catalysed

reaction process called glycolysis, to yield two molecules of

three carbon compound pyruvate, under hypoxia or anaerobic

condition, pyruvate is decarboxylated and acetaldehyde is

reduced to ethanol through alcohol dehydrogenase [57]. Xylose is

converted to Xylulose and phosphorylated to Xylulose-5-phosphate

and further metabolized to glyceraldehyde-3-phosphate, and

fructose-6-phosphate, which then enters the glycolysis pathway

for subsequent pyruvate and ethanol production [58]. It was seen

that about 60-80% of glucose was assimilated and fermented by

yeast strains within 24 h except for CY and TY strains, which

consumed less glucose but achieved a higher conversion

efficiency of 83% and 94%, respectively, compared to other yeast

strains. The highest ethanol concentration of 5.04 g/L was

recorded for MY strain with 65.3% conversion efficiency. The

least ethanol concentration was recorded for PLY, CKY, and FBJY

strains.

Xylose is the main component (1/3) of lignocellulosic biomass,

and xylose is not fermented by Saccharomyces cerevisiae

due to lack of transport system. Yeast species capable of

fermenting xylose belong to the genera Brettanomyces,

Candida, Claviospora, Kluyveromyces, Pachyysolen,

Pichia, and Schizosacchzromyces. Among

which Candida shehatea, Pachysolen tannophilus, and

Pichia stipitis ferment xylose at high concentrations

[58], and studies are being carried out to isolate

xylose-fermenting yeast strains [59–61]. In the current study

(Table 1), a higher ethanol concentration of 28.2% was recorded

for GVY followed by CY strain with 15.3% conversion efficiency

indicating the ability to ferment xylose sugar. GVY strain

produced lower conversion efficiency in glucose medium.

Co-fermentation using two different yeast species has been

carried out to efficiently utilize both xylose and glucose [19,

62]. Co-fermentation of sugars present in lignocellulose biomass

was carried out using P.stipitis and

K.marxianus and P. stiptis, and S.cerevisiae yielded

31.87g/L and 29.45g/L of ethanol [15]. In this study,

co-fermentation of glucose and xylose using yeast strain was

carried out. Acid hydrolysis of biomass releases mixed sugars

into the medium, and therefore mixed sugar fermentation was

carried out, and CY strain produced 1.83 g/L of ethanol,

achieving 27% efficiency, whereas GVY strain produced 1.8g/L of

ethanol achieving 20.6% conversion efficiency. Ethanol

production was affected in other yeast strains due to xylose,

hence the lower ethanol yield despite the presence of glucose.

Studies report that in order to improve xylose fermentation,

isolated yeast strain was grown on xylose rich media, and

efficacy of yeast strain in ethanol production was evaluated by

supplementing xylose in concentration of 10g/L or 25g/L [63].

Ethanol production by prioritized strain using

macroalgal sugars

Fermentation of macroalgal hydrolysate was carried out to

validate the potential of isolated wild yeast strains for

selection of ethanol production. Hydrolysate of E.

intestinalis and U. lactuca obtained from acid

hydrolysis were neutralized and subjected to fermentation using

each of the screened yeast individually at 35oC for

24h on an orbital shaker with 100 rpm. Reducing sugar of Ulva and

Enteromorpha are illustrated in Table 1.

Table 1. Reducing sugar profile

of macroalgal feedstock |

Macroalgae |

Glucose |

Xylose |

Mannose |

Galactose |

Arabinose |

References |

Ulva sp. |

8.2 |

4.5 |

0.29 |

1 |

0.08 |

Wal et al., 2013, Yaich et al., 2011 |

Enteromorpha sp. |

26.3 |

3.5 |

|

6 |

|

Cho et al., 2010 |

Fermentation progress was determined by measuring the reducing

sugar (after the fermentation process) and comparing it with the

theoretical yield (51% of fermented sugar) by estimating the

sugar conversion efficiency of each strain, which is detailed in

Table 2. A higher conversion efficiency of 49.4% was obtained

for CY strain for E. intestinalis followed by TY strain

42.9%. A similar study was carried out using wild yeast strains

S.cerevisiae Y12 and YPS128, derived from clean

lineages with no alternations to their genome due to human

interventions or domestication [37, 64], and this strain

fermented the hydrolysate of U.lactuca producing 7g/L

of ethanol. A multi-tolerant strain of six

Saccharomyces strains was selected and utilized for

fermentation of lignocellulose hydrolysate. This study indicates

that the natural strains outcompeted other strains for specific

traits. Yeast strains isolated from the natural environment have

the potential for bioethanol production and superior to

industrial strains obtained by tweaking the strain through

breeding, experimental evolution, or genetic engineering [34].

Free amino acid nitrogen (FAN) content in green seaweeds is >

0.15 g/L, and this avoids the need to supply additional nitrogen

sources during fermentation [37]. The FAN required for yeast

growth during fermentation and metabolism is 0.15g/L. Hence,

fermentation of seaweed hydrolysate was carried out without the

addition of nitrogen sources. Multivariate cluster analysis was

performed by selecting biochemical compositions of fruit sources

(carbohydrate, protein, fat, dietary fibers, vitamins, moisture

content and minerals) as independent variables and ethanol

production from synthetic sugar as a dependent variable. Fig.

1(b) illustrates the clustering of strains CY and TY from the

rest of the isolated strains indicating its unique properties

with the higher performance capabilities. These two strains

achieved higher biomass, longer exponential growth, maximum

conversion efficiency concerning glucose fermentation, and

exhibited temperature tolerance. Based on these criteria,

strains CY and TY were prioritized for fermentation of

macroalgal sugar.

Table. 2. Fermentation

capacities of yeast strains for synthetic sugar:

Glucose, Xylose and Glucose+ Xylose |

Glucose |

Xylose |

Glucose + Xylose |

Yeast strains |

Initial sugar g |

Fermented sugar g |

EtOH g |

Theoretical yield |

%

Conversion |

Fermented sugar g |

EtOH g |

Theoretical yield |

%

Conversion |

Fermented sugar g |

EtOH g |

Theoretical yield |

%

Conversion |

POY |

20 |

17.01±0.06 |

1.80±0.04 |

8.68 |

20.8 |

14.63±0.01 |

0.07±0.01 |

7.47 |

0.1 |

18.08±0.01 |

0.33±0.05 |

7.47 |

3.6 |

BAY |

16.36±0.14 |

3.71±0.10 |

8.34 |

44.6 |

15.63±0.01 |

0.01±0.00 |

7.98 |

0.1 |

18.27±0.01 |

1.28±0.17 |

7.98 |

13.8 |

GVY |

16.78±0.06 |

0.98±0.20 |

8.56 |

11.5 |

15.69±0.01 |

2.25±0.04 |

8.00 |

28.2 |

17.50±0.01 |

1.83±0.05 |

8.00 |

20.6 |

F3 |

15.26±0.22 |

0.48±0.01 |

7.78 |

6.2 |

13.43±0.03 |

0.05±0.02 |

6.85 |

0.8 |

17.05±0.06 |

0.08±0.02 |

6.85 |

1.0 |

TY |

2.97±0.18 |

1.42±0.02 |

1.52 |

93.7 |

16.01±0.1 |

0.04±0.01 |

8.17 |

0.6 |

16.63±0.03 |

0.02±0.01 |

8.17 |

0.3 |

CY |

3.21±0.24 |

1.35±0.04 |

1.83 |

82.5 |

18.40±0.04 |

1.43±0.01 |

9.39 |

15.3 |

13.35±0.03 |

1.83±0.05 |

9.39 |

27.0 |

CHY |

14.20±0.01 |

4.16±0.22 |

7.24 |

57.5 |

10.36±0.01 |

0.02±0.01 |

5.29 |

0.5 |

13.96±0.02 |

0.04±0.01 |

5.29 |

0.6 |

MY |

15.12±0.04 |

5.04±0.03 |

7.72 |

65.3 |

9.54±0.06 |

0.03±0.01 |

4.87 |

0.7 |

11.57±0.03 |

0.05±0.02 |

4.87 |

0.9 |

MFY |

15.25±0.02 |

4.64±0.03 |

7.78 |

59.7 |

10.21±0.12 |

0.02±0.01 |

5.21 |

0.5 |

11.57±0.11 |

0.04±0.02 |

5.21 |

0.8 |

|

Table. 3. Fermentation

capacities of yeast strains for acid treated hydrolysate

of E. intestinalis and U. lactuca

|

Yeast strains |

Enteromorpha intestinalis

|

Ulva lactuca |

Initial sugar g |

Fermented sugar g |

Ethanol g |

Theoretical yield |

%Conversion |

Initial sugar g |

Fermented sugar g |

Ethanol g |

Theoretical yield |

%Conversion |

CY |

3.74±0.15 |

3.23±0.01 |

0.81±0.01 |

1.6 |

49.4 |

3.74±0.24 |

1.97±0.01 |

0.42±0.02 |

1.0 |

41.8 |

TY |

3.20±0.02 |

0.70±0.02 |

1.6 |

42.9 |

2.02±0.05 |

0.59±0.01 |

1.0 |

57.1 |

CHY |

3.39±0.01 |

0.57±0.02 |

1.7 |

33.2 |

2.75±0.02 |

0.46±0.02 |

1.4 |

32.8 |

MY |

3.32±0.01 |

0.42±0.03 |

1.7 |

24.8 |

2.85±0.01 |

0.36±0.04 |

1.5 |

25.2 |

MFY |

3.32±0.01 |

0.50±0.02 |

1.7 |

29.5 |

2.61±0.02 |

0.42±0.03 |

1.3 |

31.8 |

GVY |

3.12±0.03 |

0.38±0.01 |

1.6 |

24.3 |

2.82±0.01 |

0.23±0.02 |

1.4 |

16.4 |

BAY |

3.08±0.01 |

0.46±0.04 |

1.6 |

29.6 |

2.73±0.03 |

0.43±0.01 |

1.4 |

31.5 |

YKY |

3.14±0.03 |

0.51±0.01 |

1.6 |

32.3 |

2.51±0.01 |

0.18±0.01 |

1.3 |

14.7 |

POY |

3.01±0.04 |

0.24±0.02 |

1.5 |

16.1 |

2.62±0.01 |

0.44±0.03 |

1.3 |

33.6 |

Yeast Identification

The identity of the prioritized yeast strains CY was confirmed as

Meyerozyma (Pichia) caribbica and TY as Pichia

kudriavzevii based on 16S rRNA

nucleotide sequences homology match within the NCBI GenBank

(Supplementary, S5). The yeast cells

were stained with methylene blue and observed under an Olympus

BX-51 bright field, phase contrast microscope, live cells reduce

the dye (methylene blue) [65] and remain colorless, whereas dead

cells retain the color and are stained blue (Fig 2 a-d). Pichia

kudriavzevii cells are oval or ellipsoidal to elongate

in the study. P.kudriavzevii is a thermo-tolerant yeast

strain isolated from fruits and food sources. In contrast, Meyerozyma

caribbica are isolated from fermented beverages having

the capabilities to ferment xylose with high efficiency [66],

which was observed in this study as well.

|

Fig 2a. Microscopic

image and Scanning electron micrographs of (CY) Meyerozyma

(Pichia) caribbica |

Fig 2b. Microscopic image and

Scanning electron micrographs of (TY) Pichia

kudriavzevii |

|

Fig 3. (a) Effect of different

concentration of salt on CY strain growth and ethanol

production (RS : Reducing sugar) |

Fig 3. (b) Effect of different

concentration of salt on TY strain growth and

ethanol production (RS : Reducing sugar) |

Fermentation of macroalgal sugar using prioritized yeast

strainsSeparate Hydrolysis (acid) and

Fermentation (SHF)

Reducing sugar from E. intestinalis and U.

lactuca was obtained by using 0.7N and 0.5N H2SO4 concentration.

About 22.4% and 19.2% sugar conversion with respect to biomass

were achieved for E. intestinalis and U.

lactuca, respectively (Table 4). The acid hydrolysate

obtained was subjected to fermentation using prioritized yeast

strains CY and TY in different combinations at 35oC,

100 rpm for 24h. Fermentation of E. intestinalis hydrolysate

using CY and TY produced 0.14g/L and 0.16 g/L of ethanol with

fermentation efficiencies of 46.9% and 51.8%, respectively.

Co-fermentation of E. intestinalis hydrolysate using CY

and TY yielded lower fermentation efficiency of 33%.

Candida sp. isolated from marine fermented red algae,

Kappaphycus alvarezii acid hydrolysate achieving 50%

fermentation efficiency [27]. E.intestinalis subjected

to SHF produced 8.6 g/L of ethanol with 30% conversion

efficiency within 48h (Cho et al., 2013). SHF of

K.alvarezii [67] and G.amansii [68] yielded

0.25g and 3.33 g of ethanol achieving 55.9% and 74.7% efficiency

respectively. Acid hydrolysis (1% v/v,

H2SO4 for 90 min) of sugarcane bagasse

pith were subjected to fermentation obtaining 2.58 g/L of

ethanol in 30h. Fermentation time for lignocellulose biomass is

longer than macroalgal biomass due to the presence of complex

polysaccharide lignin. Fermentation of U. lactuca hydrolysate

yielded lower ethanol of 0.04g/L and 0.05g/L for both CY and TY

strain with fermentation efficiencies 24 % and 48.7%

respectively. Bioethanol has been obtained from all the three

types of algae, however appropriate microorganism is yet to be

isolated which consumes pentose sugar and mixed sugar [69].

Lower ethanol yield in this study can be attributed to inhibitor

formation during acid hydrolysis. Simultaneous

Saccharification and Fermentation (SSF)

Acid pre-treated macroalgal biomass was subjected to enzyme

hydrolysis using enzyme extracted from V.

parahaemolyticus [14] and subjected to the

subsequent fermentation. SSF of E. intestinalis and

U. lactuca using CY strain produced ethanol of 0.12g/L

and 0.08g/L achieving conversion efficiencies of 45.5% and 48.7%

(Table 5). Higher conversion efficiency of 80.9% was achieved

for U. lactuca followed by 65.2% for E.

intestinalis biomass using TY yeast strain indicating

its thermo-tolerance capabilities. Similarly, Kluyveromyces

marxianus was recognized as a safe (GRAS)

thermo-tolerant yeast strain with tolerance range of 38-45oC and

producing high ethanol concentration SSF process [66].

Higher sugar conversion efficiency by these non-domesticated

(“wild”) strains Pichia kudriavzevii and Meyerozyma

caribbica indicate potential to be used at industrial

level, with strain improvement through experimental evolution,

hybridization, or genetic engineering.

Table. 4. Separate

Hydrolysis and Fermentation of dilute acid hydrolysis of

macroalgal biomass |

Seaweed

hydrolysate |

Biomass

(g) |

Acid pretreatment |

Yeast strain and fermentation

Process condition |

Initial sugar

(g) |

Fermented sugar

(g) |

Ethanol (g) |

Theoretical yield |

%Conversion efficiency |

E. intestinalis |

5 |

0.7N

H2SO4, 121oC for 45min

|

CY (35oC, 100rpm for 24h) |

1.12±0.03 |

0.58±0.03 |

0.14±0.02 |

0.30 |

46.9 |

TY (35oC, 100rpm for 24h) |

0.61±0.01 |

0.16±0.02 |

0.31 |

51.8 |

CY & TY (35oC, 100rpm for

24h) |

0.48±0.08 |

0.08±0.01 |

0.25 |

33.0 |

U. lactuca |

0.5N

H2SO4, 121oC for 45min

|

CY (35oC, 100rpm for 24h)

|

0.96±0.07 |

0.30±0.07 |

0.03±0.01 |

0.15 |

24.0 |

TY (35oC, 100rpm for 24h)

|

0.20±0.04 |

0.05±0.01 |

0.11 |

48.7 |

CY & TY (35oC, 100rpm for

24h) |

|

0.30±0.01 |

0.06±.01 |

0.16 |

40.4 |

Effect of salt on ethanol production

Marine yeast is utilized in several applications as they thrive

in harsh conditions hence tolerate higher process conditions

(salinity and temperature) [70]. In the bioethanol process,

pretreatment using dilute acid hydrolysis of marine macroalgal

biomass results in salty hydrolysate, which requires a

desalination process when employing terrestrial yeast strains,

but in the case of halotolerant yeast strains, the hydrolysate

is directly fermented to bioethanol.

Table. 5. Simultaneous

Saccharification and Fermentation of acid pre-treated

macroalgal biomass |

Seaweed

hydrolysate |

Biomass

(g) |

Acid pretreatment |

Enzyme and

Yeast strain

Fermentation process condition |

Initial sugar (g) |

Fermented sugar

(g) |

Ethanol

(g) |

Theoretical yield |

%Conversion efficiency |

E. intestinalis

|

2 |

0.7N

H2SO4, 121oC for 45min

|

S9 &CY (55oC 100rpm

for 24h) |

0.87±0.08 |

0.53±0.02 |

0.12±0.02 |

0.27 |

45.48 |

S9 & TY (55oC 100rpm for 24h) |

0.31±0.02 |

0.10±0..01 |

0.16 |

65.19 |

S9, CY &TY (55oC 100rpm for 24h)

|

0.33±0.01 |

0.06±0.01 |

0.17 |

39.04 |

U. lactuca

|

0.5N

H2SO4, 121oC for 45min

|

S9 &CY (55oC, 100rpm for 24h)

|

0.86±0.01 |

0.33±0.04 |

0.08±0.01 |

0.17 |

48.74 |

S9 & TY (55oC 100rpm for 24h) |

0.34±0.01 |

0.14±0.02 |

0.18 |

80.94 |

S9, CY &TY (55oC 100rpm for 24h)

|

0.21±0.02 |

0.04±0.01 |

0.11 |

44.67 |

CY: Cashew yeast (P. caribbica); TY:

Toddy yeast (P. kudriavzevii); S9: V.

parahaemolyticus |

Several industrial

applications have utilized salt-tolerant yeast strains such as

Debaryomyces hansenii and Zygosaccharomyces

rouxii, but not all the yeast have the ability

to tolerate high salt conditions. However, in this study, it was

seen that CY strain has consistent ethanol production till 4%

salt concentration, produced the highest ethanol of 2.6g/L from

5.95 g/L of reducing sugar achieving 88.8% fermentation

efficiency and reduced at 5% and 6% salt concentration along

with biomass. Similar results of luxuriant growth was observed

for Candida sp. isolated from a marine source in the

presence of 2-13% salt, which subsequently decreased at 14 and

15% salt [27]. Dabaryomyces, Rhodotorula Candida and

Saccharomyces exhibit tolerance to NaCl ranging from

0-16% [71]. The TY strain (Fig 3b) biomass gradually

decreased with the increase in salt concentration and

intermittent ethanol production. Highest

ethanol of 2.5g/L from 11.94g/L fermented sugar was obtained at

3% salt concentration achieving 41.45% fermentation efficiency.

At 5 and 6%, sugars were left unutilized by TY strain.

Screening of cellulolytic yeast and ethanol production

by CBP

A single strain of microorganisms that expresses cellulolytic

activity and fermentation capabilities is of potential interest

in bioethanol production as it brings down the economic burden

of enzyme production and the overall bioethanol production and

is regarded as the low-cost biomass processing [72, 73]. In this

study, prioritized strains were isolated on plates comprising 1%

CMC as the sole source of carbon (Fig 4). Hydrolytic activity

was recorded for both strains CY: 2.06 and TY: 2.69. Enzyme

activity of 1.15 U/ml and 1.19 U/ml was recorded for M.

caribbica and P. kudriavzevii at 24h

respectively (Table 6).

.png) Fig. 3 a Fig. 3 a Efect of diferent concentrations of salt on CY strain

growth and ethanol production

(RS, reducing sugar). b Efect

of diferent concentrations of

salt on TY strain growth and ethanol production (RS, reducing sugar) In CBP, cellulase production, cellulose hydrolysis, and

fermentation of subsequent sugar occur in a single reactor by a

single microbial community [74] compared to SSF. The advantage

of CBP is lower or zero capital costs for enzyme production and

compatibility of enzymatic and fermentation processes. Anaerobic

bacteria have been tested for ethanol production via CBP.

However, lower ethanol tolerance (<2%) of bacteria is a

limitation for its application at an industrial scale. In this

study, wild ethanologenic yeast strains M. caribbica

and P. kudriavzevii were used to ferment the

pre-treated macroalgal biomass E. intestinalis and U.

lactuca (Table 7). Higher ethanol conversion efficiency

was recorded for P. kudriavzevii fermenting E.

intestinalis and U. lactuca compared to the

conversion efficiency achieved through SSF process.

K.marxianus PT -1 isolated from grape fermented

Jerusalem artichoke tuber flour consisting of inulin at

40oC for 48h and achieved 90% conversion efficiency

through CBP [39]. CBP was carried out for brown algae Saccharina

japonica using engineered E.coli (BAL1611)

bacteria for 150h and obtained 4.7% ethanol [75].

SEM analysis was carried out for macroalgal biomass after CBP

process, the initial dilute-acid pretreatment provided surface

area for the yeast cells to attach and secret enzymes to degrade

the biomass. Biomass was disintegrated after CBP process

indicating the cellulolytic yeast activity (Fig 5).

CBP- compatible microorganism extensively studied is S.cerevisiae;

however, it is not suitable while employing second-generation

feedstock as it only yields higher ethanol from hexose and not

from pentose sugar [72]. Therefore, there is a need to explore

wilder ethanologenic yeast strains that exhibit higher

cellulolytic activity and be employed for CBP of

third-generation macroalgal feedstock and second-generation

feedstock.

Table 6. Enzyme activity

of yeast strains at 24h |

Yeast Strain |

Protein (mg) |

Total activity (U/ml) |

Specific activity (U/mg) |

Meyerozyma caribbica, CY |

5.23 |

1.15 |

0.22 |

Pichia kudriavzevii, TY |

5.73 |

1.19 |

0.21 |

Table 7. Fermentation

of pre-treated macroalgal biomass using cellulolytic

yeast strain through CBP |

Seaweed |

Acid Pretreatment |

Fermentation |

Initial sugar

g |

Fermented sugar

g |

Ethanol g |

Theoretical yield |

%Conversion efficiency |

E. intestinalis |

0.7N H2SO4,

121oC for 45min |

CY (35oC, 100rpm for 72h) |

1.07±0.09 |

0.56±0.02 |

0.12 |

0.29 |

43.06 |

TY (35oC, 100rpm for 72h) |

0.19±0.01 |

0.07 |

0.10 |

74.14 |

U. lactuca |

0.5N H2SO4,

121oC for 45min |

CY (35oC, 100rpm for 72h) |

1.51±0.09 |

0.95±0.02 |

0.32 |

0.49 |

64.22 |

TY (35oC, 100rpm for 72h) |

0.94±0.01 |

0.46 |

0.49 |

94.84 |

Fig 5. SEM micrographs of the

interaction between cellulolytic yeast strains Meyerozyma

caribbica on (A) E.intestinalis and

(B) U.lactuca, Pichia kudriavzevii on (C) E.intestinalis

and (D) U.lactuca

|