Introduction

Fossil fuels such as oil, coal and natural gas are the major commercial energy

sources and about 87% of global CO2 emitted due to the anthropogenic activities [1,2]

are contributed by utilization of coal (43%), oil (36%) and natural gas (20%). Earth endows finite source of oil

reserve and its increased consumption in several sectors has led to increased oil production, exerting pressure on

the reserves which is apprehended to peak and no longer suffice the world’s demand with the fast dwindling stock [3]. Rising population with higher consumption levels coupled with a fast pace of

development have spurred higher exploitation of fossil fuels leading to the escalating prices and resultant

greenhouse gases (GHGs) posing problems for planet’s climatic stability [4–6]. It is imperative

to ensure energy security through the sustainable alternative energy sources [7,8]. Globally,

nations are actively addressing the issues concerning greenhouse gases and peak oil crisis through several

mitigation measures such as; energy conservation, fuel substitution, incentives for the use of unconventional and

renewable oil, and policy reforms such as carbon tax [8]. Therefore, the current focus is on

carbon neutral renewable sources, notably photovoltaic, wind, hydrogen, etc. These alternative sources were useful

in addressing the electricity requirement, but the exploration for viable alternatives to oil in order to meet the

requirement of transport sector, etc. is quintessential. Despite the existence of possible solutions such as

renewable resources, energy efficient products (CFLs and LEDs) have not been widely adopted due to market barriers.

Wind power contributes 2.5% of world electricity output and are weather dependent, susceptible to geographic and

climatic changes [9,10]. Dependency on conventional generation coupled with the depleting stock and the enhanced

environmental awareness in the public have been the major constraints faced by the land based energy systems [11,12]. Nuclear power witnessed 2% growth in Europe, but encountered resistance with

respect to disposal of waste, safety during nuclear accident and declining global uranium stocks. Nuclear disaster

at Fukushima Daiichi nuclear power plant in 2011[13], led Germany to rethink its energy policy

[14].

India has been the 3rd largest energy consumer surpassing Russia, China and USA and about 80% of India’s

energy consumption was contributed by imported crude oil [15], which was estimated to be 213.93

Million Metric Ton (MMT) in the year 2016-17. This is attributed to the poorly endowed natural reserve of

hydrocarbon in India, however crude oil production in India is about 36.01 MMT, from the 0.3% oil reserves [15]. India is emerging as the fastest growing economy next to China with the growing

energy demand, burgeoning population (at 1.58% annual) and dwindling stock of fossil fuel in next few decades, it is

challenging to support this growing economy demand[16]. The total CO2 emission in

India accounts for 965.9Tg/yr, with electricity generation (343Tg/yr) and transport (246.23Tg/yr) sectors as the

major contributors [17]. The higher level of CO2 emissions necessitates

implementation of efficient management strategies to mitigate changes in climate [18]. The new

renewable energy resources are being explored to meet the energy demand in all sectors and also research is underway

to address the intermittency problems associated with wind and solar based energy systems [19–21].

In this context, studies have shown that biofuels are emerging as promising alternative to liquid fuels. Realizing

the potential of biomass, different technologies have evolved towards the conversion of biomass into fuels,

popularly known as biofuels [22–24]. Produced from renewable plant sources or other organic

wastes, biofuels have the advantages of cutting down carbon emission and dependency on oil [25].

In India, around 80% of rural energy [26] is met by biomass energy consumption, in the form of

firewood, agriculture residues, cow dung cake and other natural feedstock [24,27,28].

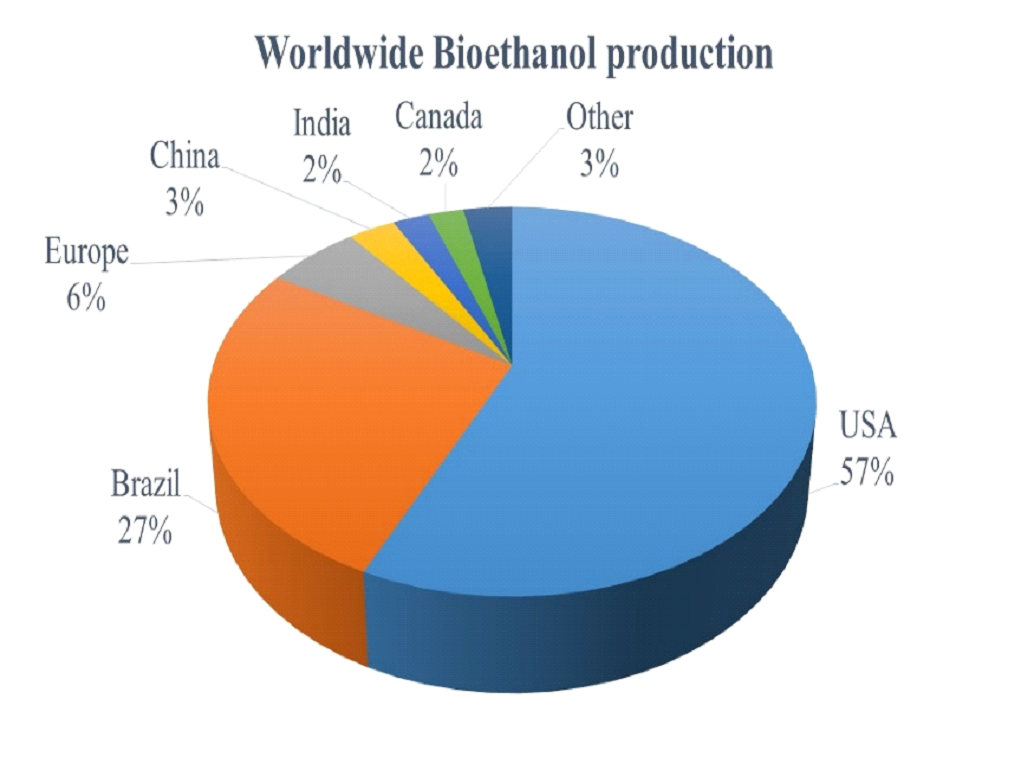

Fig. 1 represents the share of each country in the global bioethanol production, which

highlights that India’s share is only 2% [29] despite burgeoning demand for fossil fuel. This

emphasizes the need for augmentation with the viable indigenous alternative feedstock to minimize fossil fuel

dependence.

Fig. 1 Fig. 1. Worldwide Bioethanol Production

|

Biofuel from first generation feedstock involved food crops like corn and sugarcane which were exploited for biofuel

production over three decades, but this technique encountered resistance due to the limited stock and competition

with food crops [25]. The inadequacy of first generation feedstock in augmenting the growing

energy demand led to the evolution of second generation feedstock involving lignocellulose biomass (Fig.

2). However, biofuel from second-generation feedstock also failed, due to the difficulty in scaling up and

process technology involved in the cost-intensive delignification process [30]. Due to this,

the cost of production of cellulosic ethanol is two to three fold higher than the price of corn grain ethanol [31]. In the US, it was seen that, the fossil energy required to produce bioethanol from

corn, grain, soybean and wood biomass was more than the energy content of the biofuel, while sufficing only 12% of

gasoline and 6% of the diesel demand. Though first and second generation feedstock are explored for biofuel

production and assessed for carbon sequestration, environmental impacts and production potential only marginally

complies with various other sustainability criteria’s such as; disruption of global food supply, soil erosion,

extensive usage of fertilizers, conversion of ecologically vulnerable wetlands, rainforests, peat lands, savannas

into energy crop lands contributing to several magnitude of CO2 [32,33]. GHGs

footprint of major cities in India [34], recorded aggregation of carbon dioxide equivalent

emission of GHGs in the range of 13,734.59-38,633.2 Gg, with transportation being one of the major sector next to

the energy generation. Emergence of a strong global biofuel feedstock is expected to realize a positive balance

between energy and ecological footprints [35].

Table 1. Yield and Ethanol production of First, Second and Third generation feedstocks

Biofuel |

Crop |

Yield(ton/ha/yr) |

Ethanol (liters/ha/yr) |

First

generation |

Sugarcane |

50-90 |

3,500-8,000 |

Sweet sorghum |

45-80 |

1,750-5,300 |

Sugar beet |

15-50 |

1,350-5,500 |

Fodder Beet |

100-200 |

4,400-9,350 |

Wheat |

1.5-2.1 |

510-714 |

Barley |

1.2-2.5 |

300-625 |

Rice |

2.5-5.0 |

1,075-2,150 |

Irish potatoes |

10-25 |

1,110-2,750 |

Cassava |

10-65 |

1,700-11,050 |

Sweet potatoes |

8-50 |

1,336-8,350 |

Grapes |

10-25 |

1,300-3,250 |

Second

generation |

Nipa palm |

|

2,300-8,000 |

Maize |

1.7-5.4 |

600-1,944 |

Sorghum |

1.0-3.7 |

350-1,295 |

Third

generation |

Algal biomass |

730 |

23400 |

Table 1 illustrates the prospects of algal biomass emerging as an ideal alternative to the

first and second generation [37,38]. Though, algae is being utilized as an energy feedstock

since 1950s [26], the oil crisis of 1970's spurted the research [39].

Algal feedstock do not require prime agricultural land and can be grown in fresh water, wastewater [40]

and saline waters with zero nutrient input and non-interference with the land used for food production [38,41]. Algal biomass have higher photosynthetic efficiency (up to 5%) as compared to

terrestrial biomass (1.8-2.2%) [42], and require for their growth light, carbon dioxide and

nutrients (such as nitrogen, phosphorus, potassium, etc.), which are maintained through continuous flow of water [42]. Algae have a higher yield per unit area compared to terrestrial plants e.g. brown

algae under the cultured condition, yields ~13.1 kg dry weight/m2 over 7 months as compared to sugarcane

yield of ~10 kg dry weight/m2/yr [43]. Algae based on their morphology and size are

grouped into micro and macroalgae [29]. Microalgae accumulate large quantities of neutral

lipids which serves as raw material for biodiesel production [44,45], whereas macroalgae are

carbohydrate rich biomass which are useful for bioethanol production. Large scale cultivation of macroalgae in Korea

reveals an uptake of 8-10 tonne CO2 per hectare [42].

1.1 Potential macroalgal feedstock available

Marine macroalgae or seaweeds establish on hard substratum and grow luxuriantly along nutrient rich coastal zone (Fig. 3). One of the richest seaweed resources in the world is in Nova Scotia/Gulf of St.

Lawrence area [46]. Global seaweed distribution can be summarized as : (i) Least flora <200

Spp in latitudes >60o in both hemispheres, (ii) Moderate flora of 600-700 spp. that occur throughout

warm and cold tropical and temperate regions, (iii) Highest flora of 900-1100 spp. occur in four regions Southern

Australia, Mediterranean, Japan and Philippines.

| images |

Fig. 2.Evolution of biofuel production from

feedstocks and technologies |

Fig. 3. Prominent coastal regions of the world rich in seaweed

resources and potential feedstock for bioethanol production |

Seaweed resources and their uses are well established across regions in the world. Red seaweeds are mostly utilized

for extraction of hydrocolloid valuing $585 million [47] and source of food (e.g. Salads)

valuing $5 billion [48] with Asia as its prime market [43]. Cultivation of

macroalgae is a promising option as seventy percent of the Earth surface is covered by water [39,42,49,50],

therefore in order to satisfy these industrial demands, macroalgae are cultivated in large scale, mainly of the

genus Laminaria,, Undaria, Poryphyra, Eucheuma, Enteromorpha and Gracilaria representing 76% of

total macroalgae aquaculture production [51].

In recent years, algal genera of Kappaphycus, Gelidium, Gracilaria, Sargassum, Laminaria and

Ulva, (Fig. 2) are the promising potential feedstock for biofuel production in addition to

the value added products for phycocolloids extraction, human food, cosmetics, fertilizer and other chemicals [52,53]. These algal feedstock have been chosen considering the availability and

assessment of resources around the globe, ease of cultivation and harvesting. However, there is still scope to

assess other potential macroalgal species based on their availability, biochemical composition and prospects for

cultivation.

1.2 Bioethanol production from Macroalgal Feedstock

Bioethanol from algal biomass is a sustainable and eco-friendly option of renewable biofuel production [39]. Macroalgae or seaweed, saltwater thriving algae have proved to be the viable biofuel

feedstock [54] for sustainable biofuel production as it avoids the competition with fresh

water, food crops or cultivable land [39,55]. Seaweeds are multicellular marine macroalgae,

broadly grouped as green, brown and red based on the pigment present in the thallus. Seaweed consists of

carbohydrates (Table 2), which are converted to bioethanol by appropriate microorganisms such

as yeast or bacteria. The common processes involved in ethanol production are (i) pretreatment, (ii) hydrolysis and

(iii) fermentation.

1.2. Bioethanol production from macroalgal feedstock

Bioethanol from algal biomass is a sustainable and eco-friendly option of renewable biofuel production [39]. Macroalgae or seaweed,

saltwater thriving algae have proved to be the viable biofuel feedstock

[54] for sustainable biofuel production as it avoids the competition with

fresh water, food crops or cultivable land [39,55]. Seaweeds are

multicellular marine macroalgae, broadly grouped as green, brown and

red based on the pigment present in the thallus. Seaweed consists of

involved in ethanol production are (i) pretreatment, (ii) hydrolysis and

(iii) fermentation.

1.3 Pretreatment and Hydrolysis for extraction of macroalgal sugar

Different types of biomass contain different amounts of sugars and the complexity of the biomass is reflected between

structural and carbohydrate components [62,63]. Plant biomass is mostly composed of lignin

(13.6-28.1%), cellulose (40.6-51.2%) and hemicellulose (28.5-37.2%) biopolymer [64], which

serves as raw material for production of fuels. However, critical step involved in biofuel production is the

conversion of biomass to sugars [65]. It is therefore important to carefully choose the

pretreatment process based on the biomass and an optimal pretreatment process towards better yield of sugar with the

low energy input [66].

Pretreatment involves physical, chemical and biological (or combinatorial) process to expose the cell constituents

and cell wall materials of feedstock [67]. Physical pretreatment involves reduction in size of

the feedstock to increase the surface area for better transport of acid/base catalysts, enzymes and steam to the

fibers (cellulose) [68]. Chemical pretreatment involves dilute acid, alkaline, ammonia, organo

solvent and other chemicals. Biological pretreatment involves microorganisms like bacteria and fungi (rich in cellulase

enzyme) to degrade the biomass and release the sugars [69]. Integrated pretreatment involves

combination of all the process such as acid catalyzed steam explosion, ammonium fiber explosion (AFEX), acid

pretreated enzyme hydrolysis etc [66].

First generation biomass is starch based and requires no stringent pretreatment conditions to extract sugar, whereas

lignocellulose biomass is complex in structure due to the presence of biopolymer lignin that embeds cellulose in a

matrix resulting in a higher degree of polymerization and crystallization, which is the main factor responsible for

recalcitrance [66,70–72] requiring a high cost for delignification process [73].

Therefore, the process of sugar extraction requires severe pretreatment conditions such as steam explosion at 200

oC [74], at 121 oC [75], AFEX, Sulphite pretreatment

to overcome recalcitrance of lignocellulose (SPORL) [31], pressurized steam liquefaction [76]. It is seen that alkaline based pretreatment is effective in solubilizing significant

portion of lignin from lignocellulose biomass [69]. Lignin was removed from cotton stalk

pretreated using sodium hydroxide at high temperature and 96% fermentable sugars were recovered [77,78].

Around 11.4 MMT cotton plant wastes available in India, can generate 3,533 billion litres of ethanol considering 90%

fermentation efficiency [78]. Removal of 89% lignin and 69.77% hemicellulose in rice husk was

achieved through wet air oxidation pretreatment method [79]. Hydrothermal pretreatment of wheat

straw was carried out and viewed under scanning electron microscope (SEM), which reveal partial de-fibration of the

lignin fibers due to pretreatment, whereas in delignification process lignin appears as layer of globular deposits

exposing the cellulose structure [71].

Compared to this, macroalgae with the large concentration of structural polysaccharides (Table

3) and low lignin contents [80] requires mild and low-cost processes for extraction of

sugars. The most widely used chemical pretreatment method for macroalgal biomass is dilute acid (Table

4), as it solubilizes hemicellulose and exposes cellulose fibers for further enzyme hydrolysis [68]. The energy consumed in acid pre-treatment is comparatively low as compared to other

pre-treatments and higher sugar yields are achieved [69]. Dilute acid concentration for

hydrolysis varies based on the feedstock, listed in Table 3. However, limitation of dilute

acid pretreatment is the formation of Hydroxymethyl furfurals (HMF) and Levulinic acid (LA) resulting from the

degradation of sugars that inhibit the subsequent process (fermentation) in ethanol production [81,82].

These inhibitors are mitigated by neutralization process before fermentation [83,84] or by

employing other sustainable alternatives such as biological pretreatment: enzyme hydrolysis [53,85–94].

Enzyme hydrolysis of cellulose is carried out efficiently by cellulolytic (cellulase) enzyme, which

is comprised of exo-, endo-glucanases and cellobiase (β- D-glucosidase) enzymes [71]. Endoglucanases

cleave cellulose at random sites of β-1, 4-bond and form free reducing ends and short-chain oligosaccharides [84] Exoglucanases cleaves the accessible ends of cellulose molecules to liberate

glucose and cellobiose. β- D-glucosidase hydrolyses soluble cellobiose and other cellodextrin to produce glucose

molecules [95]. Enzyme conversion is substrate specific without any by-product formation. The

process could be enhanced [7], by exposing the cellulose fibres through pre-treatment using

acid. Enzymatic hydrolysis disintegrates the cellulose and hemicellulose into simple sugars [96]. Along with this, depolymerization of xylan (polysaccharide composed of xylose) can

be achieved by dilute-acid pretreatment [88] with about 64% xylose conversion efficiency.

Pretreatment techniques include high thermal liquefaction process (HTLP) [97], alkali

pretreatment, CaO, Ozonolysis, etc. However it was seen that the acid treated biomass was more susceptible for

enzyme attack than HTLP, NaOH, CaO and other pretreatment [87].

Algal cell wall is composed of cellulose Iα (triclinic crystalline form) unlike the cellulose Iβ (monoclinic

crystalline form) in plant cell wall. Cellulose Iα consists of weaker hydrogen bonds resulting from spatial

arrangement of individual cellulose chains, resulting in easy access to endocellulases enzymes during enzyme

hydrolysis [98]. Most common categories of enzymes considered for cell wall depolymerization

are cellulases, hemicellulases and accessory enzymes [99], produced from wood-rot (soft rot)

fungi such as Trichoderma, Penicillium, and Aspergillus [100]. The

production costs of these enzymes are relatively higher.

Table 2

Detailed characteristics of different types of Seaweeds |

Characteristics |

Green seaweed |

Red seaweed |

Brown seaweed |

Number of species recorded |

6032a |

7105b |

2039c |

Habitat |

Freshwater and Marine |

Strictly marine |

Strictly marine |

Photosynthetic pigment present |

Chlorophyll a, b, carotene

and Xanthophyll |

Phycoerythrin |

Fucoxanthin |

Photosynthetic rate (µmol CO2 /h) g/dry |

30 to 1786 |

20-1808.7 |

100-500 |

Productivity [dry g/(m2 year)] |

7100 |

3300-11300 |

3300-11300 |

Nature of cell wall |

Cellulose, pectin rarely hemi-cellulose |

Cellulose and pectic material with polysulphate esters |

Cellulose with alginic acid and fucocinic acid |

Sexuality |

Isogamy to oogamy |

Advanced and complex (oogamous) |

Isogamy to oogamy |

No. of flagella and their insertion |

2 or 4, equal anterior, whiplash |

Absent |

Only in reproductive cells, 2 unequal, lateral whiplash and tinsel |

Cell structure |

Eukaryotic |

Eukaryotic |

Eukaryotic |

Phycolibins |

Absent |

Allophycocyanin,

r-Phycoerythrin

r-Phycocyanin |

Absent |

Carotenoids |

α-, β-, γ- carotene |

α-, β- carotene |

α-, β-, ε- carotene |

Xanthophylls |

Lutein

Prasinoxanthin |

Lutein |

Fucoxanthin, Violaxanthin,

Diadinoxanthin, Heteroxanthin,

Vacheriaxanthin |

Carbohydrate (%) |

30-60 |

30-50 |

20-30 |

Protein (%) |

10-20 |

6-15 |

10-15 |

Lipid (%) |

1-3 |

0.5-1.5 |

1-2 |

Ash (%) |

13-22 |

5-15 |

14-28 |

Photosynthetic reserve*

(Stored food) |

Starch |

Floridean starch (intermediate between true starch and dextrin) |

Laminarin and mannitol (hexahydride alcohol) |

Source: [50,54,56–61] |

Table 3

Sugar profile of Macroalgae |

|

Green seaweeds |

Red seaweeds |

Brown seaweeds |

Structural polysaccharide |

Cellulose |

Cellulose, lignin |

Cellulose, Alginate |

Storage polysaccharide |

Starch, Ulvan, Mannan |

Agar, Carrageenan |

Fucoidan, laminarin |

Monosaccharides |

Glucose, Mannose, Rhamnose, Xylose, Galactose |

Glucose, Galactose, Agarose |

Glucose, Galactose, Fucose, Xylose |

Sugar alcohol |

|

|

Mannitol |

Sugar Acid |

Uronic acid, Glucuronic acid |

|

Uronic acid, Mannuronic acid, Glucuronic acid, Alginic acid |

Commercial industrial enzymes are produced from aerobic

fungi

Trichoderma reesei, which produces over 100 g per liter of crude cellulase enzyme with higher

specific activity, achieved by genetic engineered strains

[101]. Most common enzymes employed

for seaweed hydrolysis are commercial enzymes such as Cellulase, Celluclast 1.5 L, Viscozyme L, Novozyme 188,

Termamyl 120 L, β-glucosidase, Multifect, Meicelase, Amyloglucosidase etc operated at pH 4.5-5.5 and temperature

35-55

oC, incubation time varies based on the algal feedstock

[56,71,

,89,90,103–109].

Cellulase producing microbes have been screened and isolated from various sources such as soil from forest and nature

reserves, hot water springs, marine bacteria [90] compost, sewage, animal manure and bovine

rumen [91]. Enzymatic hydrolysis has been done conventionally at <50oC, resulting

in lower sugar yield [95]. Therefore, research is under progress for isolating efficient

cellulolytic enzyme systems from a wide variety of bacteria, fungi, aerobes, anaerobes, mesophiles, thermophiles and

thermo-stable microbes [92,93,96] which can overcome low sugar yield for biofuel production.

Cellulase from thermophilic and psychrophilic microbes are preferred as they are resistant to high and low

temperatures respectively [91]. Thermo-stable enzymes increase solubility of reactants and

products, facilitating easy recovery of end products [96] while reducing hydrolysis time,

decreasing contamination and cost of energy.

Marine fungus Cladosporium sphaerospermum was isolated to extract cellulase enzyme and used to hydrolyze

U. pertusa biomass, which yielded 112 mg/g of reducing sugar at pH 4 and temperature 25 oC for

42 h [94]. Similarly, marine bacteria was isolated from degrading U.lactuca to extract

cellulase enzyme, which is tolerant to high salt concentration and alkaline pH [86].

Polysaccharolytic enzymes extracted from the gut of the abalone Haliotis midae degraded the polysaccharides

laminarin, carboxymethylcellulose (CMC), alginate, agarose and carrageenan [109].

1.2.2 Fermentation of macroalgal sugars

Macroalgal biomass contain different types of polysaccharides, exclusively composed of glucose i.e., glucans. Main

glucans present in green: cellulose and starch; red: cellulose and floridean starch; brown: cellulose and laminarin

[46,50,61]. Non-glucans are sulphated polysaccharides such as agar, carrageenan and alginate.

In order to obtain higher ethanol, hydrolysis of glucan as well as non-glucan with the fermentation of the resulting

sugars is essential [60]. Sugar released from the pretreatment process has been fermented using

microorganisms such as yeast, bacteria, and fungi, which ferment these sugars to produce ethanol as a by-product [41,110]. Saccharomyces cerevisiae is the commonly used yeast microorganism for

fermentation as it readily ferments glucose [111]. However, pretreatment releases mixed sugars

namely; glucose, galactose, mannitol, rhamnose and xylose. Due to the lack of xylose transport system,

S.cerevisiae is not capable of utilizing xylose [112]. Its uptake takes place through

glucose transport system and is regulated by the concentration of glucose. At only low concentration of glucose,

xylose is consumed by the yeast [113]. As a result, studies related to isolation of wild yeast

strains from various sources is done that can ferment both hexose and pentose sugars yielding higher ethanol.

Bacteria, yeast and fungi are explored for xylose fermenting organisms, and mostly preferred organisms are bacteria

and yeast as fungi are too slow for competitive industrial process [7].

Single or combination of strains are being attempted for utilization of sugars. Laminaran and mannitol obtained from

L. hyperborea were subjected to fermentation using one bacterium (Zymobacter palmae T109) and

three yeast strains (Pichia angophorae, Pacchysolen tannophilus and Kluyveromyces marxianus). It was seen

that only P. angophorae is capable of fermenting laminaran and mannitol at higher oxygen

transfer rate to produce 0.43 g ethanol/g substrate [114]. Utilization of mannitol by Zymobacter

palmae resulted in the production of 0.37 g ethanol/g mannitol [115], however

mannitol was utilized at lower oxygen rate in fermentation media. Mannitol was effectively fermented by

E.coli KO11 for production of 0.41 g ethanol/g mannitol [116]. Similarly, glucuronic

acid fermentation was attempted using Pachysolen tannophilus and E.coli.

Bioethanol production from all forms of macroalgal biomass; wet, dried and residues (after extraction of

hydrocolloid) was attempted. Residues after extraction of hydrocolloids are rich in cellulose, which have been

utilized for bioethanol production. Floating residue of

Table 4

Bioethanol production from macroalgal biomass |

Green Seaweeds |

Pretreatment

conditions |

Enzyme hydrolysis

conditions |

Yeast/Bacterial strain and Fermentation process |

Reducing Sugar g/L |

Ethanol yield g/g |

Theoretical yield (%) |

Reference |

E.intestinalis |

Hydrothermal process

(75mM for 90min) |

Celluclast 1.5 L and Viscozyme L

(55oC, 120 rpm for 54h) |

Saccharomyces cerevisiae KCTC 1126

(pH 5.5, 30oC, 220 rpm for 12h) |

40.4 |

0.21 |

41.74 |

[120] |

U.fasciata |

H2SO4

(0.1% at 100oC for 1h) |

Cellulase 22119

(Sodium acetate buffer pH 4.8 at 45oC for 36h) |

Saccharomyces cerevisiae

(109 CFU/ml 28oC, 120rpm for 48 h) |

20.6 |

0.45 |

88.24 |

[89] |

U.lactuca |

|

Cellulase isolated from Cladosporium sphaerospermum

(pH 4, 25oC, 42h) |

Saccharomyces cerevisiae MTCC180

(28oC for 12h) |

112mg/g |

0.47 |

92.16 |

[94] |

U.pertusa |

Citric acid buffer

(0.1M sterilized using autoclave) |

Meicelase

(combined saccharification)

(pH 5.5, 50oC, 100rpm for 120h) |

Saccharomyces cerevisiae IAM4178

( 30oC for 36h) |

59.1 |

0.47 |

91.24 |

[70] |

HTLP+Enzyme

(150oC, 15 min) |

Cellulase & Amyloglucosidase

(pH 4.8, 50oC, 150rpm for 24h) |

Saccharomyces cerevisiae ATCC24858

(pH 5.5, 150rpm, 30oC for 24h) |

26 |

0.48 |

93.51 |

[97] |

Red Seaweeds |

G. elegans |

|

Meicelase

( pH 5.5 at 50oC for 120h) |

Saccharomyces cerevisiae IAM4178

( 30oC for 36h) |

49 |

0.38 |

73.63 |

[70] |

G. amnasii |

H2SO4

(56-168mM ,45-240min) |

Enzyme Viscozyme L (0.024 FBG/ml) |

Scheffersomyces stipitis

(pH 5.5, 30oC, 200rpm) |

43.5 |

0.47 |

92.40 |

[108] |

|

H2SO4

(2%, 150oC for 4h) |

|

Brettanomyces custersii KCCM11490

(pH 4.8-5.5, 27-30oC) |

42.2 |

0.38 |

74.51 |

[126] |

G. verrucosa |

H2SO4

(1.5%, at 80oC for 2 h) |

|

|

87 |

0.43 |

84.29 |

[60] |

373mM H2SO4 |

Celluclast 1.5L and Viscozyme L

(pH 5, 45oC, 150rpm for 72h) |

Saccharomyces cerevisiae KCTC1126

(pH 5, 30oC, 150rpm for 114h) |

20.4 |

0.48 |

94 |

[110] |

Gracilaria sp. |

H2SO4

(0.1N,121oC for 30min) |

Commercial enzyme

(pH 4.5, 50oC) |

Saccharomyces cerevisiae

( 30oC for 48h) |

11.46 |

0.42 |

82.80 |

[132] |

K. alvarezii |

Soaked in 1.6 L distilled water for 30 min and boiled at 90oC for 1 h |

Celluloclast 1.5 L & Novozyme

(pH 5, 50oC, 150 rpm for 24h) |

Saccharomyces cerevisiae

(pH 5,35oC, 130 rpm for 6h) |

79.2 |

0.25 (SHF) |

49 |

[88] |

0.27

(SSF) |

52.9 |

H2SO4

(0.2M, 130oC for 15min) |

|

Commercial brewer’s yeast

(30oC 120 rpm pH 5 for 72 h) |

20.4 |

0.21 |

41.18 |

[133] |

H2SO4

(0.9N, 100oC for 1h)

5 cycles |

|

Saccharomyces cerevisiae NCIM

(5% v/v, 30oC 150 rpm, pH 6.4-6.8 for 48 h) |

51.9 |

0.42 |

82.36 |

[117] |

P. palmata |

Acid hydrolysis |

|

|

21.84 |

0.173 |

33.92 |

[133] |

Brown Seaweeds |

A. crassifolia |

Citric acid buffer

(0.1M sterilized using autoclave) |

Meicelase

(5g/l at 50°C for 120 h) |

Saccharomyces cerevisiae IAM 4178

(30oC for 36h) |

66.3 |

0.38 |

75 |

[70] |

L. hyperborea |

Extracted in water at 65°C |

|

Pichia angophorae |

30 |

0.43 |

84.31 |

[114] |

|

Extracted in water 121oC for 20min |

|

Zymobacter palmae

(pH 6, 30oC) |

3.8 (mannitol) |

0.38 |

74.51 |

[115] |

S. sagamianum |

|

|

Pichia stipitis

(pH 5, 200rpm) |

19.8 |

0.35 |

69.32 |

[125] |

S. janponica |

H2SO4

(1mM, 121oC, for 120min) |

Cellulase and cellobiase

(pH 4.8, 50oC, 150rpm for 48 h) |

Saccharomyces cerevisiae

(pH 6.5, 30oC for 36 h) |

34 |

0.41 |

80.74 |

[103] |

Acid hydrolysis

(0.1N, 121oC for 15min) |

Celluclast 1.5L, Viscozyme L, Novoprime 959, Novoprime 969 or AMG 300L

(50oC, 150rpm for 24h) |

E.coli KO11

(30oC for 24 h) |

30.54 |

0.41 |

80.39 |

[116] |

H2SO4

(40mM , 121oC for 60min) |

Novozyme

(Termamyl 120L) |

Pichia angophorae KCTC 17574

(5% 30oC at 200 rpm, 136h) |

45.6 |

0.16 |

33.3 |

[52] |

Shredding and enzymatic

(23oC for 30min) |

|

Ethanol Red yeast

(32oC) |

35 |

0.45 |

88.24 |

[126] |

U. pinnatifida |

Dilute acid

(5% H2SO4, 120oC for 24h) |

Celluloclast 1.5L & Novozyme188

(pH 4.6, 45oC) |

E.coli

(pH 7,170 rpm, 37oC for 12h) |

20 |

0.144 |

28.2 |

[107] |

L. japonica was subjected to acid pretreatment

followed by enzyme hydrolysis, an ethanol yield of 14 g/L was obtained from 34 g/L of reducing sugar achieving 41.2%

conversion efficiency

[103]. Similarly,

K. alvarezii dried residues after extraction

of sap were utilized for production of bioethanol

[117]. Wet biomass of

G. amansii was

used as bioethanol feedstock,

Brettanomyces custersii KCTC 18154P strain

was utilized for

fermentation of the hydrolysate due to the ability of the strain in exhibiting co-fermentability. Utilization of raw

or wet macroalgal biomass is not feasible for bioethanol production due to high viscosity of the medium for

fermentation

[118]. In green seaweeds, studies have focused on conversion of cellulose and

starch to bioethanol. Whereas conversion of other sulphated polysaccharides such as Ulvan to produce ethanol is yet

to be explored

[60]. Non availability of natural strains capable of fermenting alginate, a

major polysaccharide of brown algae

[60], makes it difficult to achieve higher ethanol

production.

Fermentation is carried out in two process, Separate Hydrolysis and Fermentation (SHF) and Simultaneous

Saccharification and Fermentation (SSF) [119]. SHF involves hydrolysis and fermentation

performed sequentially, whereas SSF involves performing simultaneous hydrolysis and fermentation [74].

Saccharina japonica, Undaria pinnatifida and Poryphyra were subjected to SSF using Pichia

angophorae KCTC strain and obtained 7.7 g/L of ethanol [52]. SHF process is

faster but presence of inhibitors resulting from acid pretreatment has significant impact on yeast microorganisms.

SSF is preferred over SHF as the sugars released are readily metabolized by yeast microorganisms, which results in a

faster ethanol production rate and lower capital costs. SSF has a drawback due to the difference in temperature

optima of cellulase (50oC) and fermenting microorganism (35oC). SHF and SSF

of Enteromorpha intestinalis or Ulva (Enteromorpha) intestinalis produced 8.6 g/L and 7.6 g/L with

30.5% and 29.6% fermentation efficiency respectively. Conversion of ethanol to acetic acid by yeast and suboptimal

temperature of 30 oC than the optimum temperature of 55 oC for enzyme activity was attributed

to the lower ethanol yield in SSF [120].

Higher temperature shortens the exponential phase of the yeast cell [121] affecting the ethanol

production. However, this has been overcome through thermotolerant yeast strains or cell immobilization technique

which allows higher processing temperatures [120–123]. Thermotolerant yeast

species such as Candida tropicalis and Kluyveromyces marxianus (38-45oC) are mainly

utilized to produce bioethanol from lignocellulosic biomass [123,124].

Bioethanol production from macroalgae utilized commercial yeast strains such as S. cerevisiae KCTC 1126 [110,111], MTCC 180 [60], IAM 4178 [70], ATCC 24858

[97], KCTC 17574 [52], Pichia stipitis [125], Pichia angophorae [114], Scheffersomyces

stipitis [108], Brettanomyces custersii KCCM 11490 [126], Ethanol red yeast [36] and bacterial strains such as Zymobacter

palmae [115] and Escherichia coli SJL2526 [107]. Fermentation of macroalgal polysaccharides is carried out at pH 4.5-6.8

and temperature 25-30 oC and the incubation time is largely strain dependent. The yeast growth rate is

dependent on temperature and fermentation time [131]. However, exponential phase of yeasts are shortened at large

temperatures and pH < 4, requiring longer incubation for higher ethanol production, as reported in S.cerevisiae

BY4742 [64]. Shorter fermentation time causes inadequate growth of microorganisms resulting in inefficient

fermentation [132].

In order to optimize ethanol yield and improve substrate utilization range [129], studies

focused on immobilization of yeast cells [121,130]. Immobilized yeast cells have enhanced the

ethanol productivity and reusable for 15 cycles with bacterial cellulose-alginate sponge [121].

Free and immobilized strains were used for molasses fermentation. Free cells were unable to ferment at temperatures

greater than 38 oC, compared to immobilized yeast. Immobilized yeast strains exhibited both psychrophilic

and thermo-tolerant characteristics, suitable for fermentation in a wide range of temperatures [131]

and increased ethanol yield and higher cellular stability, while reducing downstream processing expenses [132]. Fermentation of U.lactuca biomass done using immobilized Saccharomyces

cerevisiae strain, yielded ethanol (concentration of 12 g/g of sugar) with conversion efficiency of 47.1%

[130]. Table 4 summarizes ethanol yield from the three types of

macroalgae along with the process conditions and strains utilized for hydrolysis (pretreatment) and fermentation.

Fermentation of red seaweed Gracilaria using free yeast cells yielded 0.41 g/g of ethanol and immobilized

yeast cells yielded 0.42 g/g achieving 80 and 82.8% fermentation efficiency [132].

Studies emphasize on production of bioethanol from readily available carbohydrates of brown and red seaweeds, but

utilization of red and brown seaweeds such as Kappaphycus, Gelidium, Gracilaria, Sargassum, and Laminaria

have the likelihood to override the existing multi-billion dollar hydrocolloid industry [89].

This can be addressed in two ways: (i) utilization of cellulosic rich residue after hydrocolloid extraction, (ii)

exploration of green seaweeds which are abundantly recorded from various estuaries and abandoned aquaculture ponds

across maritime states in India [134]. Green seaweeds exhibit characteristics of a potential

feedstock for biofuel production by their cosmopolitan distribution, wide environmental tolerance, higher growth

rates and year around productivity [135]. In India, seaweeds are seldom consumed as a food

source, and the suitability for biofuel production is still underexplored as several species accumulate different

levels of carbohydrate. Seaweeds contain low amounts of polysaccharides composed of glucose, highlighting the need

for ethanol production from carbohydrates including sulfated polysaccharides, sugar acids and sugar alcohols. Not

all the reported microorganisms are capable of fermenting these sugars and a major limitation is lack of tractable

microorganisms that can efficiently ferment all sugars extracted from seaweed into ethanol. Isolation of yeast

strains to ferment both pentose (C5) and hexose (C6) sugars are vital for achieving high ethanol yield. In this

backdrop, the current study explores bioethanol prospects from viable feedstock habituated in the west coast of

India, which involves:

- screening and prioritizing potential macroalgal feedstock for bioethanol production based on the biochemical

composition;

- comparative performance analysis of chemical and biological pretreatment method for extraction of sugar from

macroalgal biomass; and

- bioethanol potential assessment of green seaweeds and comparative analysis of ethanol yield across macroalgal

species.