ENVIS Technical Report: 89, July 2015 |

|

|

|

Biodiversity, Ecology, Energy, Landscape Dynamics & Hydrology of Agastya Foundation Campus, Kuppam |

|

| T.V. Ramachandra* | Harish R.Bhat | Bharath H. Aithal | Rao G. R. | Sudarshan P.Bhat |

| Vinay S. | Ganesh Hegde | Gouri Kulkarni | Bharath H. Aithal | Vishnu D. Mukri |

*Corresponding author: cestvr@ces.iisc.ac.in, energy@ces.iisc.ac.in [080-22933099]

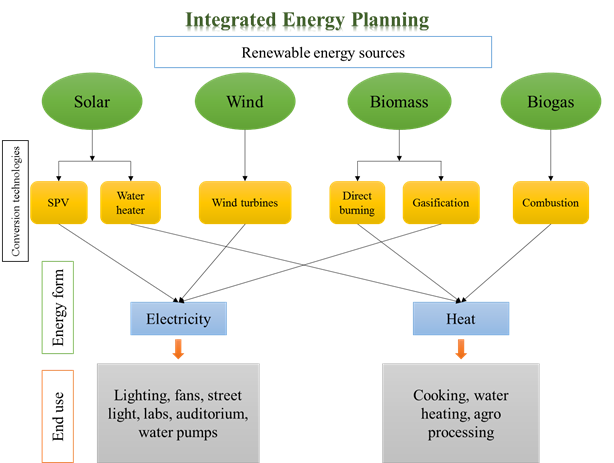

Energy is essential for economic and social development of a region or a nation. However, consumption of fossil fuels is the major cause of air pollution and climate change. The threat posed to sustainability by greenhouse gas emissions and deterioration of the natural resource base (for example oil crisis, Fuel wood scarcity, etc.) has caused worldwide concern. Improving energy efficiency and de-linking economic development from energy consumption (particularly of fossil fuels) is essential for sustainable development of a region. The energy sector, on one hand, is a part of the economy and on the other hand it itself consists of parts such as energy supply and energy demand interacting with each other. Both these interactions are of immense complexity. Energy is required for all the economic activities. Energy supplies are essential for both intermediate production as well as final consumption. So, economic development is dependent on the energy system of the country. In turn, the implementation of technologies or improvement of the energy system is dependent on economic factors such as capital costs, energy prices etc. Also, the demand supply balances involve the flow of energy from source as primary energy to service as useful energy. At each stage of the energy flow, technologies are involved with different conversion efficiencies and losses India has abundant renewable energy resources such as solar, wind, biomass, etc. which are environmentally benign and can effectively meet energy demand. About 5200 MW of power generating capacity based on renewable energy sources has been installed in the country so far, which constitutes about 3.8% of the total installed capacity. The effective transition from a fossil fuel driven energy system to the renewable energy systems is possible only through the policy shift, capacity building, strengthening institutions and building infrastructure. There is a need for strengthening of existing research institutions and creation of a few centers of excellence that have state of the art research / testing facilities for renewable energy technologies. Centralised energy planning exercises cannot pay attention to the variations in socio-economic and ecological factors of a region which influence success of any intervention. Decentralised energy planning advocated these days is in the interest of efficient utilisation of resources, ensuring more equitable sharing of benefits from development. The regional energy planning endevaour needs to focus on the area based decentralised energy plans for meeting energy needs for subsistence and development with least cost to the environment and the economy. The regional planning mechanisms take into account all resources available and demand in a region. This implies that the assessment of the demand and supply, and the intervention in the energy system which may appear desirable due to such exercises, must be at a similar geographic scale. For example, bioresource assessment of supply and demand at the aggregate level is likely to be misleading as scarcity and surplus is always at a localised level. Consequently, the energy interventions in the form of energy supply enhancement, containing demand and/or encouraging alternative fuels may be aimed at the wrong area or target group.

Ecologically sound development of the region is possible when energy needs are integrated with the environmental concerns at the local and global levels. Energy planning entails preparation of area based decentralised energy plans for meeting energy needs for subsistence and development with least cost to the environment and the economy. The need to search for renewable, alternate and non-polluting sources of energy assumes top priority for self-reliance in the regional energy supply. This demands an estimation of available energy resources spatially to evolve better management strategies for ensuring sustainability of resources. The spatial mapping of availability and demand of energy resources would help in the integrated regional energy planning through an appropriate energy supply - demand matching.

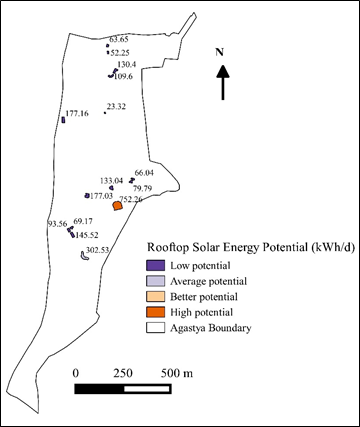

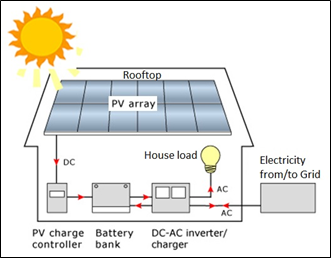

Typical solar rooftop system for Parijata guest house: Table 1 shows the typical rooftop solar PV system which can be installed in the guest house. Capital cost and technical specification to the load of one room is computed which can be deduced to any number of rooms and estimation holds good for other guest house in the organisation.

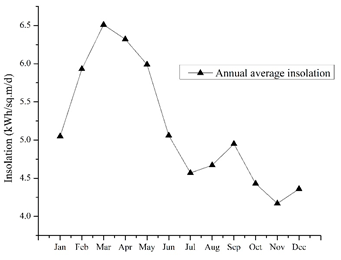

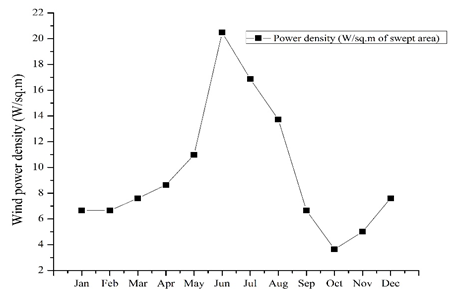

Solar Street light is one of the applications of SPV system which helps to provide light to remote locations. Agastya organisation has already installed few solar street lights (and few of them were non-functional). Battery is an important component of the solar street light system which needs regular maintenance and observation. It must be placed in a water proof dry container and shielded from dust, moisture and insects. Distilled water level in the battery should be checked once in 3-4 month and complete charge drain (or over changing) be avoided to enhance the life of these batteries. Panels shall be cleaned regularly since dust accumulation and bird droppings are common. Regular maintenance and servicing will enhance the lifespan with higher conversion efficiencies. Wind energy scenario: Region has a lower average wind speed which less than 2.5 m/s in most of the months. During June and July region experiences higher wind speed of over 3 m/s. Figure 4 gives the monthly variation in wind power density in Agastya foundation region. The wind power density ranges from 3.64 W/m2 (October) to 20.5 W/m2 (June) in the region. It shows that, low speed vertical axes wind turbines are feasible for small capacity electricity generation, which may be integrated with solar PV systems.

Wind Energy Conversion System (WECS) uses wind to convert mechanical energy into electrical energy. Main components of WECS are blades, gears, turbine, a generator and a pillar to mount all the equipment at the required height. Wind potential assessment is a prominent pre-installation procedure to assure perfect selection of a site to harness maximum energy.

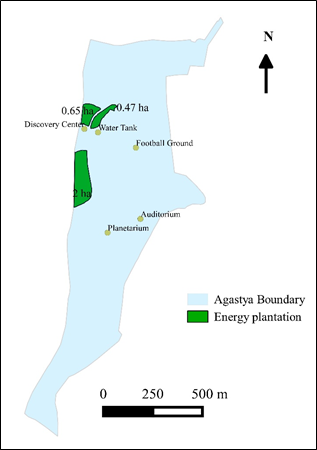

Bioenergy prospects Agastya foundation is spread over 172 acres which mainly has scrub/grass land with few trees. There are few patches with exotic species - Acacia (Acacia auriculiformis) and Nilgiri (Eucalyptus tereticornis) in the region, and the biomass may be used for energy. Biomass gasifier can be used to generate electricity which can meet the motive (water pumps) and mechanical (workshop/construction) electricity demand. The organisation is located in the arid region and suitable for energy plantations. Technically, energy plantation refers to growing high biomass yielding species of trees and shrubs which are harvestable in a comparably shorter time and are explicitly meant for fuel. The biomass harvested from trees are mostly dry due to the weather which can be further dried in sunlight for better combustion. The fuel wood may be used either directly in wood burning stoves and boilers or processed into methanol, ethanol and producer gas. The energy plantations provide inexhaustible renewable sources (with recycle time of 3-8 years) of energy and provide reliable electricity. The key features of energy plantations are given in Table 3.

Selection of multipurpose species provides a number of by-products like oils, organic compounds, fruits, edible leaves, forage for livestock, etc. [7]. Data collected from Forest Department reveals that annual woody biomass available is in the range 11.9 to 21 t/ha/yr. An energy forest raised at Hosalli village in Tumkur district to support a wood gasifier plant has annual yield of 6 t/ha/yr. Singh and Tokay [8] have concluded that energy plantations of different species shown net productivity of 15.7 to 32.62 ton/ha/yr. after 4 years of planting, which is shown in the Table 4. Table 4: Net productivity of Energy plantation [8]

Trees can be planted in the periphery of football playground selecting some fruit bearing trees which also give shades and biomass. Grasslands are to be retained un-disturbed which shelters vast insects and grass hoper which is linked to the bird diversity. However, few fruit bearing trees and scrub flora can be planted in these areas which help bird nesting and attract butterflies. The organisation has many Acacia auriculiformis and Eucalyptus tereticornis trees, which may be harvested in phased manner and planting of native species suitable for bioenergy would help in addressing the energy requirement while enhancing the local ecology.

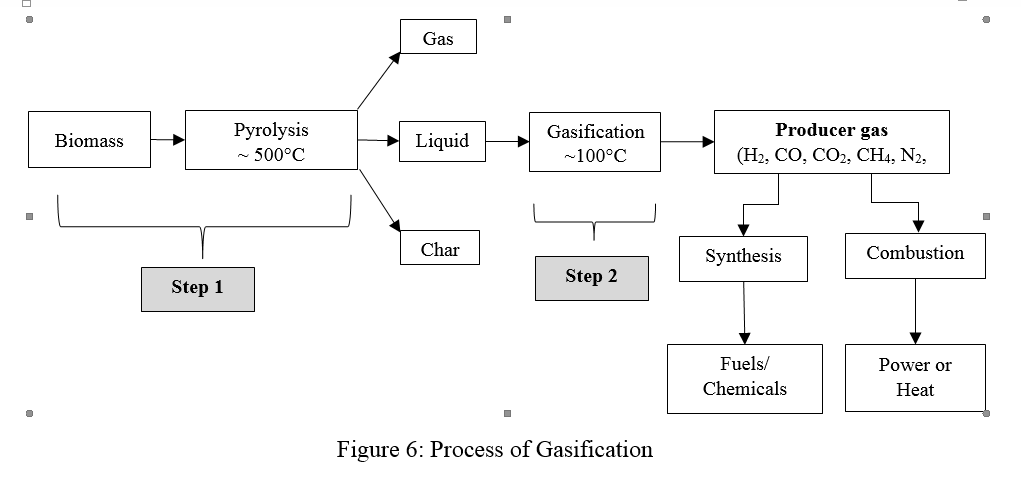

Electricity generation from biomass gasification Fuel wood can be converted into gas using thermo-chemical processes with only 2 - 4% of ash. Gasification is carried out in oxygen starved environment to generate carbon monoxide and hydrogen which are combustible. The reactions are carried out in elevated temperature of 500-1,400 °C and pressure of 33 bar (480 psi). Air based gasifiers normally produce gas with high nitrogen content, whose calorific value varies between 4 and 6 MJ/Nm3 (100-1200 kilo calories/Nm3). Oxygen and steam based gasifiers produce gas with relatively high calorific value of 10 to 20 MJ/Nm3. Gas generated from biomass is also called as Producer gas which is highly combustible [9].

(Source: NREL)

(Source: Biomass gasifier-based power generation system back to basics, with a difference, The Energy and Resource Institute. (http://www.teriin.org/index.php?option=com_content&task=view&id=59)) The capacity of the biomass based electricity generation ranges from few kilowatts few hundreds of kilowatt. Fuel requirement for gasifier is about 1.2 kg to generate 1 kWh of electricity which runs for 4 to 5 hours/day. These types of systems are best suited for distributed generation, have the capacity to meet the demand of domestic electricity consumption. Remote area electrification is possible where the conventional grid supply is not feasible [11]. Producer gas can be used with conventional fuels such as diesel or natural gas which allows 60-80% savings in fossil fuel consumption. MNRE (Ministry of New Renewable Energy, http://www.mnre.gov.in) is encouraging gasifier projects for both in community level and for individual household. Central Financial Assistance (CFA) is being provided for various components of gasifier plants from 15,000 per kW to 5 lakhs (one time) depending upon the application and benefitting population. Also the ministry organizes technical courses for technicians in order to understand the technology and for effective implementation [12]. Biogas generation The organization has few cattle which produce sufficient dung to produce biogas. Hundreds of students come to the organization every day, who produce significant amount of food waste which can be used along with animal residue to produce biogas. The wet organic residues offer very high potential of biogas production which can meet the cooking fuel demand in guest house or of employee colony. The slurry generated in the biogas production is good manure which can be used to prepare compost or directly fed to agricultural or horticultural plantations. Biogas mainly comprises of methane (60-65%) and carbon dioxide (35-40%) having a small fraction Hydrogen sulphide and water vapour. Biogas generation from dung, organic waste or agricultural and horticultural residues is dependent on temperature, carbon-nitrogen ratio (C:N), pH and retention period. Temperature is the most prominent factor that affects the biogas generation; The optimum conditions for biogas generation are: temperature 30-35°C, pH 6.8-7.5, carbon : nitrogen ratio (C:N) 20-30, solid contents 7-9%, retention time 20-40 days. The retention period decides the rate of digestion, longer the retention time more the gas generated for a given amount of waste. There are many technologies available for biogas generation depending upon the availability of resources. The most widely used technologies are:

Arrangements may be made to collect food waste. Waste collection and transportation to the biogas plant will be easier and effective. Significant amount of biogas can be generated from above mentioned technologies which can be used for coking or electricity generation.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||