Materials and methods |

Aerobic composting was carried out in rectangular polythene containers of volume 25 l and provided with perforations on the lid as well as on the sides to help aeration. The material to be composted was mixed with biogas digester liquid and 5% previously generated compost to help start the compost process. The overall process was carried out similar to the decentralized micro-composting methods normally adopted that are similar to turned windrows. No temperature control was exercised. The composting material was wrapped in nylon mesh and was placed in the rectangular polythene container to prevent interference by insects and vectors. Once a week these nylon mesh wrapping were opened, contents mixed and replaced in the wrapping. Feedstocks such as fruit waste, paddy straw and leaf litter were used without size reduction. Newsprint and photocopier paper were hand shredded to 3–4 cms, while sugarcane bagasse was chopped to 3–5 cm length prior to placing in the compost bins. Packing density (kg/dm3) of these materials vary from 0.17 (for fruit waste), 0.12 (leaf litter), 0.12 (photocopier paper), 0.11 (newspaper), 0.07 (paddy straw) to 0.07 (sugarcane bagasse).

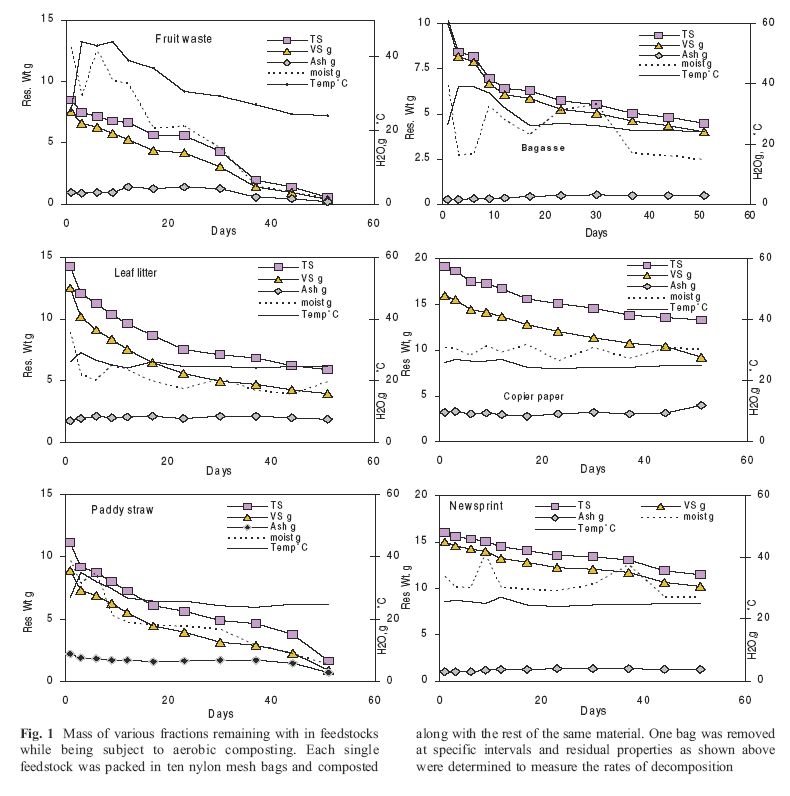

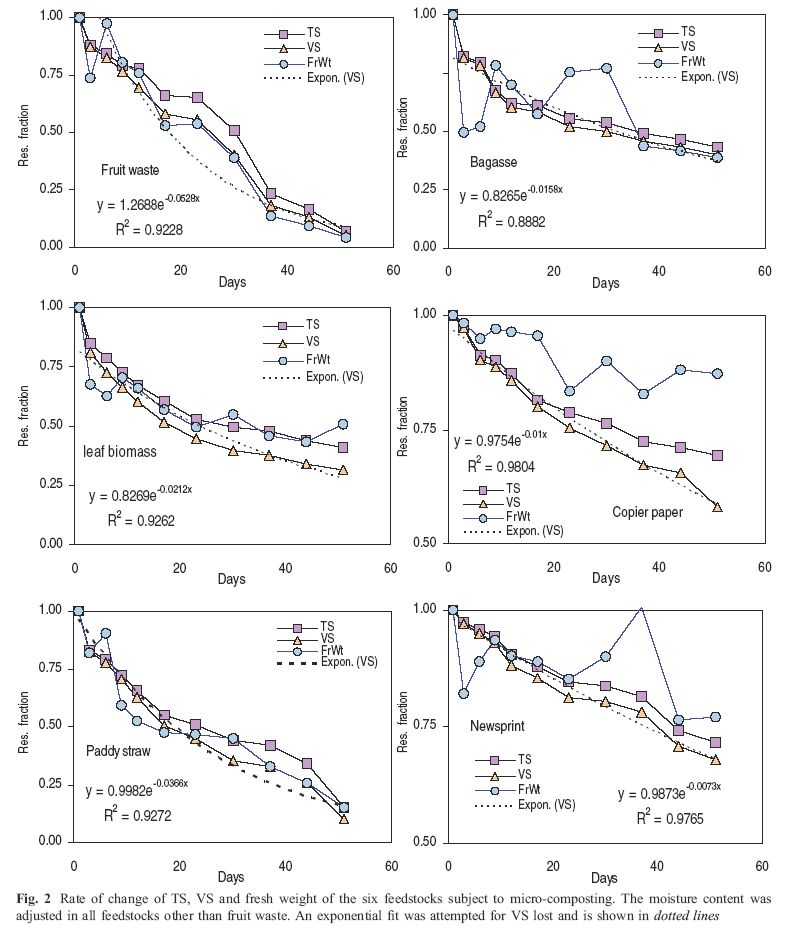

Decomposition rate and change in decomposition indicators were determined by subjecting each type of feedstock sample to varying decomposition duration within a pile. Ten nylonmesh bags containing 50 or 100 g

portions of the feedstock were placed within the composting material and removed at specific intervals. At the time of weekly mixing or when required, one bag of each of these six feedstocks was removed from the composting pile and subject to physico-chemical analyses. Sampling was carried out on 0, 3, 6, 9, 12, 17, 22, 30, 37, 44 and 51 days. These represent intervals where appreciable weight change was expected to occur. For each of the container, prior to weekly mixing, leachate collected was drained, its volume measured and its COD, BOD, TS, VS were determined by standard methods. The loss in VS, measured as a fraction of the original VS mass added, was plotted for each of the feedstock along with an exponential fit calculated by spread-sheet software.

Six different location specific (representative)

OFMSW constituents were studied. Fruit waste,

soiled newsprint, leaf litter and photocopier paper

represent wastes from areas with fruit juice stalls,

service and catering area, gardens and walkways and

photo-copier service areas respectively (Sathishkumar

et al. 2001). Leaf litter studied here represents a wide range of fallen tree leaves with an age on the ground

ranging from 1 to 10 days. This suggests that leaves

will be in various stages of decomposition and do not

represent green leaves harvested from trees and

subsequently dried. Paddy straw (packing material)

and sugarcane bagasse (waste collected after juice is

pressed out and this differs from sugar industry

bagasse in many ways) are found in locations specialized in metal furniture making (or bulk fruit

packing) and sugarcane juice stalls on streets respectively.

Anaerobic digestion of bagasse to biogas using

a stratified-bed fermentation technique has been

studied previously (Chanakya et al. 1999). Paddy

straw and bagasse served as internal standards for the

study with respect to anaerobic digestion and biogas

potential. Food and vegetable wastes have been

studied intensively and were not considered for study

here. The sources and the quantity of each of the six

feedstock composted in plastic bins are presented in

Table 1.

Biological methane potential (BMP) was determined by fermenting powdered dry feedstocks at 1 and 2% TS in 133 ml serum vials. The required quantity of dried and powdered feedstock (0.5 and 1.0 g) feedstock was placed in serum vials. Fifty milliliters of biogas digester liquid previously enriched withmethanogens was added to these vials (five replications) and the air in the headspace was immediately displaced with biogas from a biomass fed biogas plant, the bottles capped, crimped and incubated upside down. Within a few minutes, the biogas in the headspaces of the vials was replaced by oxygen-free nitrogen. Nitrogen was bubbled into the fermenting liquid with a long hypodermic needle and the headspace gas was vented with a short needle to keep it at atmospheric pressure. The head space gas composition was determined immediately for all the vials in a gas chromatograph with a Porapak-Q column connected to a thermal conductivity detector. These vials were subsequently incubated upside down at 35°C in an incubator. The gas production in these vials was determined by releasing the headspace gas through a hypodermic needle into an inverted burette filled with water. Any gas production accumulating in the headspace of the vials would thus result in it being released into the burette and its volume is read directly in the burette. The composition of gas in the head space was determined each time the gas was released into the inverted burette. In this way the volume and composi- tion of the gas produced was recorded for a period of 90 days. The interval for gas measurement was chosen from past experience to ensure that significant volume could be recorded each time and also the volume of gas production did not exceed the capacity of the burette. From this data it was possible to estimate the volumes of methane and carbon dioxide produced at various periods. The production of a continuously high fraction of methane is expected to indicate a healthy anaerobic decomposition process. The cumulative gas production was recorded and their average was used for arriving at conclusions on suitability for anaerobic digestion and biogas recovery.